EN | FR | ES

Home >> Shaft Seals >> DMR Bearing Isolators

Bearing Isolators - Protech Seal

Daemar Bearing Isolators (Protech Seals) are designed to protect bearings with zero lubricant leakage and total exclusion of contaminants. Below is the most common profiles that are available.

Bearing Isolator Technology

The unique technology has been developed over a number of years to provide total bearing protection by ensuring zero leakage of lubricant to atmosphere and total exclusion of contaminants from the bearing housing. Lip seals are primarily designed to keep lubricants in, and are not always effective at keeping contaminants out. Surveys have shown that even a tiny amount of water or dirt in the lubricant can drastically reduce bearing operating life.

Unique Design

The DMR Bearing Isolator is based on a simple, unitized, two-piece design normally manufactured in chemically resistant PTFE. The product range Bearing Isolator ProTech consists of a complete family of complementary designs that provides outstanding performance for virtually any application. Applications with pressurized, flooded, or sealed bearing housings can now benefit from Types FS and FN, which feature an internal lip seal, again offering benefits of zero leakage and zero entry of contaminants.

Applications

High-grade PTFE composites in the construction of the standard bearing isolator range ensure a wide range of operating capabilities, including high and low temperature and extreme chemical environments. The use of alternative PTFE fillers extends the physical properties and capabilities into such areas as food production and pharmaceuticals. DMR Bearing Isolators can normally replace existing sealing devices, without modification to the equipment.

Extending equipment operating life across these industries:

- Chemical Processing

- Pulp and Paper

- Oil and Gas

- Mining

- Food and Beverage

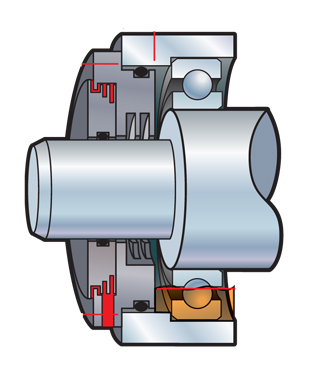

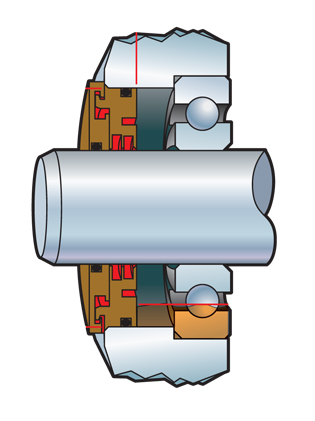

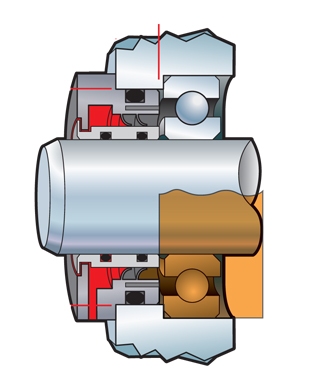

LS Series

Flanged General purpose sealing in a flanged design. PTFE material. Excludes heavy water spray and dry contaminants from the bearing cavity. Retains grease and oil splash (oil level must be below inboard oil drain-back or non-flooded).

Applications: electric motors, pumps, mixers, gear boxes, blowers and custom equipment.

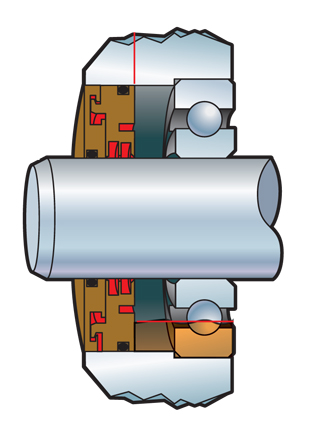

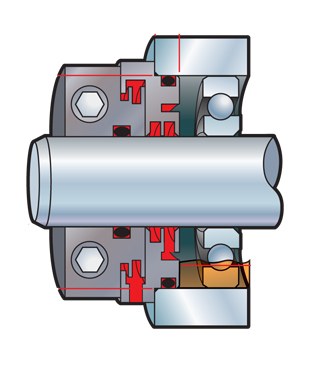

LN Series

Non-Flanged- Specifically designed for flush mount applications. General purpose sealing in non-flanged design. PTFE material. Excludes heavy water spray and dry contaminants from the bearing cavity. Retains grease and oil splash (oil level must be below inboard oil drain-back or non-flooded).

Applications: electric motors, pumps, mixers, gear boxes, blowers and custom equipment.

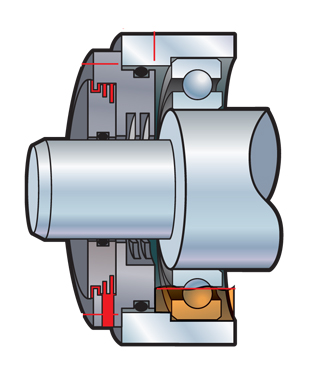

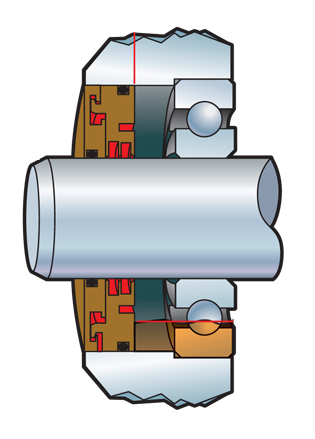

LW Series

Wrap Around- Specifically designed for heavier water spray exclusion. PTFE material. Excludes heavy water spray and dry contaminants from the bearing cavity. Retains grease and oil splash (oil level must be below inboard oil drain-back or non flooded).

Applications: electric motors, pumps, mixers, gear boxes, blowers and custom equipment.

LX Series

Wrap Around- Specifically designed for heavier water spray exclusion. Vertical up option design is "LX" same as "LW" but with no drain port. PTFE material. Excludes heavy water spray and dry contaminants from the bearing cavity. Retains grease and oil splash (oil level must be below inboard oil drain-back or non flooded).Applications: electric motors, pumps, mixers, gear boxes, blowers and custom equipment.

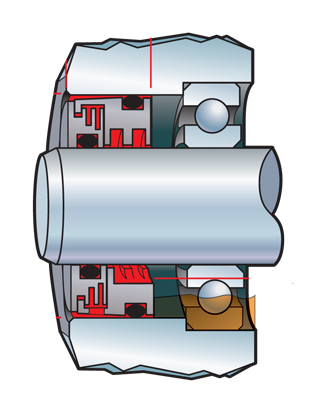

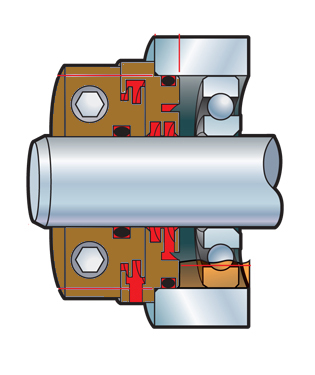

ML Series

Flanged Millennium-Specifically designed for heavier water spray exclusion. Bronze material. Also excludes dry contaminants from the bearing cavity. Retains grease and oil splash (oil level must be below inboard oil drain-back or non-flooded).

Applications: electric motors, pumps, mixers, gear boxes, blowers and custom equipment.

MN Series

Non-flanged Millennium- Specifically designed for flush mount applications. General purpose sealing in non-flanged design. Bronze material. Excludes heavy water spray and dry contaminants from the bearing cavity. Retains grease and oil splash (oil level must be below inboard oil drain-back or non-flooded).

Applications: electric motors, pumps, mixers, gear boxes, blowers and custom equipment.

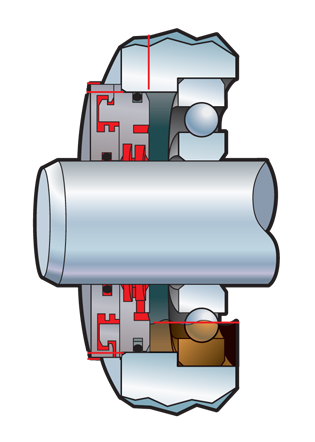

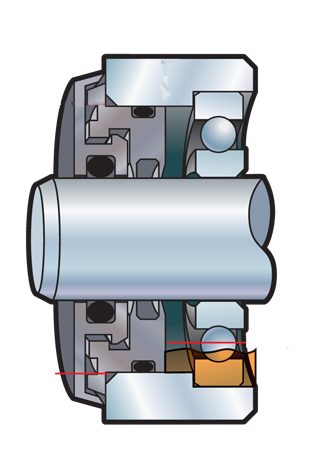

MX Series

The metallic design for vertical up, non-flooded applications where a metallic seal is preferred. Ideal for sealing and protecting the bearing housings of electric motors, pumps, mixers, gear boxes, turbines, blowers and custom equipment against heavy water spray and dry contaminants. Excellent for retaining grease and oil splash, however the oil level must be below the inboard oil drainback of the seal (non-flooded). Specifically designed to exclude contaminants in vertical up applications, and can run dry or with grease or oil lubrication.

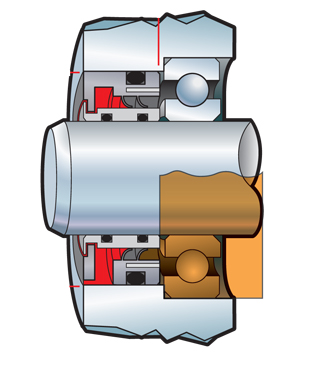

FN Series

Non-flanged 360- Specifically designed for oil flooded and oil mist applications where seal must be flush mounted. Maximum 5 psi (.03 bar) internal pressure. PTFE material with stainless steel rotor. Excludes heavy water spray and dry contaminants from the bearing cavity.

Applications: electric motors, pumps, mixers, gear boxes, blowers, cooling towers, aerators and custom equipment. Oil mist lubrication systems.

FS Series

Flanged 360- Specifically designed for oil flooded and oil mist applications. Maximum 5 psi (.03 bar) internal pressure. PTFE material with stainless steel rotor. Excludes heavy water spray and dry contaminants from the bearing cavity.

Applications: electric motors, pumps, mixers, gear boxes, blowers, cooling towers, aerators and custom equipment. Oil mist lubrication systems.

SL Series

Split- Split design for field retrofits where equipment can not be uncoupled or disassembled. Requires no wear sleeves or shaft refurbishment. PTFE material. Excludes heavy water spray and dry contaminants from the bearing cavity. Retains grease and oil splash (oil level must be below inboard oil drain-back or non flooded).

Applications: electric motors, pumps, mixers, gear boxes, blowers and custom equipment.

SM Series

Split MILLENNIUM® metallic bearing isolator, for time-saving retrofit installation, flange mounted Split design, non-contacting metallic bearing isolator enables time-saving, no tear-down installation on rotary shaft equipment. Labyrinth design provides unsurpassed two-way protection.

WD Series

Wash Down- Wash down purpose in narrow flanged designs. PTFE material. Specifically designed to exclude high pressure water spray and dry contaminants in limited space applications. For grease retention.

Applications: Small disposable electric motors and equipment for food processing industry. Economical for 140 & 480 frame IEEE 841 electric motors.