Home >> Industry and Applications >> Food and Beverage Processing

Food and Beverage Processing

The importance of consumer safety and the nature of the Food & Beverage Industry’s processing environments dictates the use of components that meet a demanding list of standards and regulations. Daemar’s lineup of Essential Components has been developed to provide confidence to manufacturers that their products will perform in these types of environments. Whether it be Metal Detectable Seals that help prevent product contamination or Washdown Bearing Isolators that protect bearings, gearboxes and motors from the aggressive procedures of equipment sanitation and washdown

Daemar’s Food & Beverage Industry Brochure highlighting product solutions for the industry.

Solutions for Food & Beverage

Our components are found in many types of equipment operating in the demanding sanitary environments of the Food & Beverage processing industry. Our seals, o-rings, bushings, retaining rings and shim are essential components in valves, pumps, gearboxes, motors and conveying equipment. Selecting the correct material and design for these components is crucial to the longevity of your processing equipment and can help reduce maintenance costs and downtime.

These components are designed and engineered to perform in the harsh food and beverage environment; the products must be resistant to the food materials they are exposed to, they must also be able to withstand the regular cycle and chemicals of washdown. There is the added level of complexity created by the Government regulations and standards for products involved in food and beverage processing operations.

X-Ray and Metal Detectable Seals

Designed to work with any Food Processing conveyor, pipe line or free fall detection system, these industry specific parts can help eliminate product recall, lower product loss and stop distribution of contaminated product.

Developed for microbial, high-temperature and mechanical applications, metal detectable o-rings and hydraulic seals are available in a range of elastomers including: Buna, EPDM, Viton and Silicone. More>>

Custom Metal Detectable Seals

Daemar manufactures custom metal detectable seals made from materials such as Polyurethane (PU), EPDM Rubber, and Fluoro Rubber (FKM). These seals are precision-machined to meet specific application requirements, these seals enhance HACCP and FDA compliance, reduce product recalls, and maintain the high safety standards required in the Food & Beverage Industry. More >>

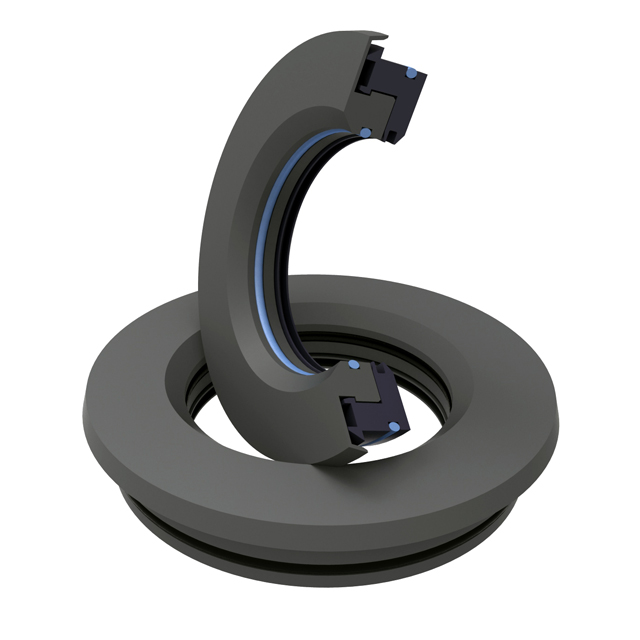

Washdown (WD) Bearing Isolators

Machine downtime due to bearing failure is costly. By keeping lubrication in and contaminants out, bearing isolators provide reliable protection of rotating equipment for extended bearing life – particularly in high pressure food and beverage wash down conditions. Labyrinth sealing technology applied to high performance materials allows ProTech WD Profile bearing isolators to operate far beyond shaft speed limits of standard radial lip seals and avoid shaft wear. More>>

Additional features include:

- Delivers highest level of exclusion against high-pressure water spray and dust

- Meets IP-56, IP-66, and IP69K testing for dust and water exclusion

- Specifically designed to exclude high pressure water spray and dry contaminants in limited space

- Food grade and anti-microbial material available per ASTM JIS Z2801 testing

- Not compatible with oil lubricated systems.

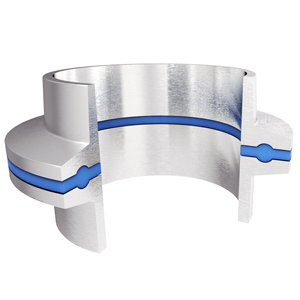

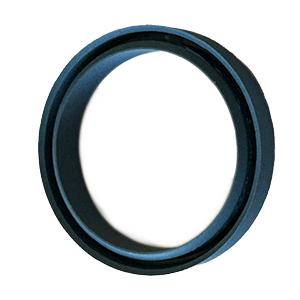

Sanitary Gaskets

Hygienic seals and sanitary gaskets are used widely in the Biotech, Pharmaceutical, Dairy, Food & Beverage, Industrial and Semi Conductor industries to seal clamp connections in sanitary pipe lines. DMR sanitary gaskets are available in a range of FDA compliant elastomers, fluoroelastomers and Kalrez perfluoroelastomers. For applications that require USP Class VI, we offer compounds in EPDM, Viton, Silicone and PTFE to meet these standards. More>>

Braided Packing

PTFE packing, interlock braid with a break-in lubricant. Food Grade FDA PTFE filaments and break-in lubricant. Manufactured from pure PTFE yarns lubricated with a food grade breakin lubricant. 154FDA complies with the FDA and USDA requirements under Title 21 Food and Drugs, 178.3570, Lubricants with Incidental Food Contact, 177.1500, Perfluorocarbon Resins. 154FDA contains only materials permitted for food contact use by U.S. Department of Agriculture and the Food and Drug Administration. More>>

Application Equipment:

- Rotating and reciprocating equipment

- Valves

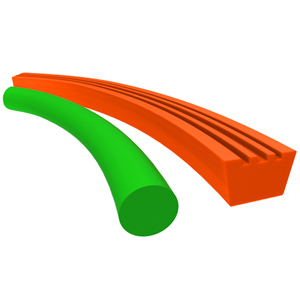

Urethane Belts

Vee and Round Urethane drive belts available in FDA/USDA grade materials and a range of durometers and diameters for the specific application. Supplied from cord stock and fabricated to the exact size required, the belts can be bonded on site. More>>

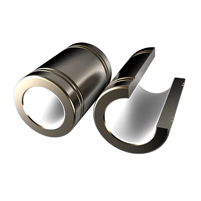

FDA-USDA Self Lubricating Bearings

These bearings offer food process, pharmaceutical, packaging machinery and medical equipment engineers 3 off-the-shelf, FDA/USDA compliant linear bearing options. More>>

- FDA/UDSA Compliant Linear Bearings

- Fluidline Linear Bearings

- FDA Lite™ Linear Motion Bearings

PTFE Encapsulated Viton® O-rings

PTFE Encapsulated Viton® o-rings are o-rings consisting of a seamless and uniform PTFE FEP/ PFA encapsulation/jacket which completely encloses a core material Viton® fluoroelastomer (also available in silicone). The combination of these components creates an o-ring that is virtually chemically inert and compression set resistant for use in harsh sealing environments. Encapsulated o-rings will decrease downtime and hence increase profitability wherever corrosive fluids and gases cause premature seal failure. More>>

Features:

- High Chemical Resistance

- Low Coefficient of Friction

- FDA compliant

- Outperform solid PTFE

- Low Compression Set

- Non Stick Surface

Custom Metal Detectable Seals

Daemar manufactures custom metal detectable seals made from materials such as Polyurethane (PU), EPDM Rubber, and Fluoro Rubber (FKM). These seals are precision-machined to meet specific application requirements, these seals enhance HACCP and FDA compliance, reduce product recalls, and maintain the high safety standards required in the Food & Beverage Industry. More >>