EN | FR | ES

Home >> Shaft Seals >> DMR Bearing Isolators >> MX Series Bearing Isolator

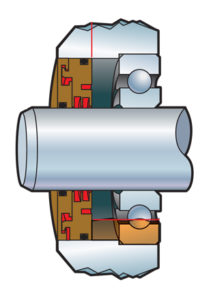

MX Series - Bearing Isolator

MX – MILLENNIUM® design metallic bearing isolator, flange mounted without drain port

Technical Specifications

- OPERATION TYPE: Non-Flooded

- MAXIMUM SURFACE SPEED: Up to 7,000 fpm (35 m/s)

- PRESSURE RATING: 0 psi

- AXIAL MOVEMENT: 0.020 inch (0.51 mm)

- ECCENTRICITY: 0.020 inch (0.51 mm)

- OPERATING TEMPERATURE: -40° to 400 °F / -40° to 204 °C

- SHAFT DIAMETER: 0.610 to 12.000 inch (15.5 to 304.8 mm)

- BORE DIAMETER: 1.004 to 13.575 inch (25.5 to 344.8 mm)

- SEAL MATERIAL: Bronze, Stainless Steel, Carbon Steel, Other Alloys

- O-RING MATERIAL: FKM is standard. Alternates available

Performance Advantages

Machine downtime due to bearing failure is costly. By keeping lubrication in and contaminants out, Parker’s bearing isolators provide reliable, two-way sealing protection of rotating equipment for extended bearing life. Labyrinth sealing technology applied to high performance materials allows MILLENNIUM® MX Profile bearing isolator to operate far beyond shaft speed and temperature limits of standard radial lip seals and avoid shaft wear.

The non-contact design has virtually no torque consumption, will not wear or groove shafts, and allows for non-lubricated dry running. It also accommodates the greatest axial movement in the industry, reducing a major factor that causes labyrinth seal failure.

We can custom engineer solutions to meet exacting specifications for either new or retrofit applications. When used to replace seals during planned or unplanned rebuilds, the MILLENNIUM MX Profile lowers shaft cost due to liberal specifications. Costs can also be eliminated on tooling charges due to the fact that ProTech is a precision-machined seal.

Design

The MILLENNIUM design is the first and only metallic isolator that is unitized without internal o-rings or locking rings. A proprietary unitization mechanism reduces potential leak paths while a non-wearing internal diffuser provides optimal spacing during installation and eliminates metallic dusting during start-up.

An external O-ring on the outside diameter of the stator allows for easy seal installation, maintains a press fit in the seal housing, and provides a static seal against the bore for oil retention. The stator has a sophisticated series of grooves to retain oil splash, which is proven to be the most effective design for oil retention when compared to various competitor designs.

The rotor uses an external O-ring to maintain a static press fit on the shaft. Since the rotor spins with the shaft, it will not wear, groove, or damage the shaft. This eliminates costs associated with having to recondition the sealing surface of the shaft.

The rotor and stator are assembled at the Parker facility where they are permanently unitized, allowing for a one-piece installation. This unitized design also maintains the seal’s integrity by keeping high-pressure water spray, vibration or axial movement from separating or increasing the gap between the rotor and stator.

Additional design features include:

- Reduced flange diameter on many sizes minimizes seal O.D. to equipment housing obstruction issues for easy installation

- Internal PTFE diffuser eliminates metallic dusting during initial start-up

- Minimal gap between the diffuser and rotor minimizes vapor flow through seal

- Specifically designed for excluding heavy water spray

- No external drainport

Applications

The MILLENNIUM MX Profile is our metallic design for vertical up, non-flooded applications where a metallic seal is preferred. It is ideal for sealing and protecting the bearing housings of electric motors, pumps, mixers, gear boxes, turbines, blowers and custom equipment against heavy water spray and dry contaminants. The MX design is excellent for retaining grease and oil splash, however the oil level must be below the inboard oil drainback of the seal (non-flooded). The MILLENNIUM MX is specifically designed to exclude contaminants in vertical up applications, and can run dry or with grease or oil lubrication.

Total Eccentricity: 0.020” (.51 mm)

Shaft Speed: Up to 7,000 fpm (35 m/s)

Maximum internal pressure: 0 psi (0 bar)

Axial Movement: 0.020” (0.51 mm). Special designs up to 0.100” (2.54 mm)

Shaft/Bore: Tolerances ±0.002” (±0.05 mm). Special designs available

Materials

Stator & Rotor: Available in various metallic materials, listed below.

- Bronze (Standard)

- 304 Stainless Steel

- 316 Stainless Steel

- Carbon Steel

O-Rings: Come standard as FKM, but are also available in:

- NBR

- FDA silicone

- Fluorosilicone

- EPDM

- Aflas®

Size Range

The MILLENNIUM MX profile in standard shaft diameters ranging from 0.610” to 12” (15.5 mm to 305 mm). Because this is a precision machined seal, we can manufacture virtually any configuration.