Home >> Seal >>O-Rings >> Kalrez O-Rings >> Kalrez Industry Applications >> Semiconductor

Semiconductor Processing Seals

Field-Proven Contamination Control

Purity is critical to high wafer yield, and Kalrez® seals are designed with properties that help reduce contamination from particulates, outgassing and extractables.

![]()

Kalrez® seals for semiconductor processing are field-proven in the manufacture of semiconductor chips.

They can help extend planned maintenance intervals, and thereby lower long-term cost of ownership, in a wide range of semiconductor processes. In a number of fabrication customer evaluations, Kalrez®seals exhibited improved mechanical strength, lower particle generation and longer seal life versus competitive perfluoroelastomers, in both static and dynamic sealing applications.

Operations Improvements

Kalrez® seals can help improve semiconductor manufacturing in a range of wafer-fabricating operations, including:

- Deposition

- Etch

- Ash/strip

- Thermal

- Wet

| Process Environment | Suggested Product |

|---|---|

| HDPCVD/PECVD/ALD | Kalrez® 9100 |

| SACVD | Kalrez® 9500 |

| Dielectric Etch | Kalrez® 9300 |

| Conductor Etch | Kalrez® 9500 |

| Ash/Strip | Kalrez® 9500 |

| Thermal | Kalrez® 8900 |

| Wet | Kalrez® 6375UP |

Better Performance for Spansion

Spansion, the largest provider of flash memory solutions, turned to DuPont for material options that would produce longer seal life with reduced particle generation. High particle count and leaks from seal erosion and compression set caused seal issues in multiple processes. Kalrez® 9100 parts exhibited significantly less seal erosion, reduced particle generation, and provided better elastic recovery characteristics. View Spansion Semiconductor O-rings Case Study

A Proven Leader

When IMEC tested Kalrez® 9100 seals versus incumbent seals in an isolation valve and top nozzle position, the 9100 seals appeared undamaged and exhibited no sign of cracking after 5000 cycles.

These results inspired the international research center IMEC in Belgium to change the perfluoroelastomer seals on all positions to Kalrez® 9100 seals. View IMEC Case Study

Latest Product Offering Targeted for Semicon Fabrication

The latest perfluoroelastomer offering from DuPont, Kalrez® 9600 provides longer seal life by offering enhanced performance properties in an array of aggressive and emerging high-temperature plasma applications.

Kalrez® 9600 is an innovative product for the semiconductor fabricating industry and builds on the performance of the market leaders, Kalrez® 9100 and Kalrez® 9500. It offers lower defectivity and longer seal life with better sealing functionality at higher temperatures in vacuum plasma processes.

Targeted applications for Kalrez® 9600 include those especially suited to plasma deposition applications such as atomic layer deposition and chemical vapor deposition, as well as etch processes used to fabricate next-gen chips in the semiconductor industry.

Features

Standard Kalrez® O-Ring Compounds

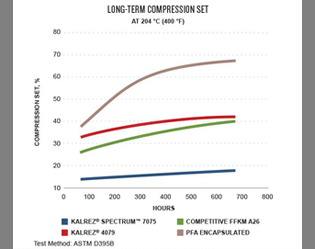

Kalrez® Compounds – 4079

4079 perfluoroelastomer parts are a black, low compression set product for use in many dry and wet semiconductor process environments. It has excellent chemical resistance, good mechanical properties and outstanding thermal stability.

Kalrez® Compounds – 6375

6375 is designed to give outstanding performance in the widest possible range of chemicals and temperatures. This product is an excellent choice for use in acids, bases, amines, steam, ethylene oxide, and many other aggressive chemicals.

Kalrez® Compounds – 7075

7075 is designed for general-purpose use as O-rings or custom sealing components in the chemical and hydrocarbon processing industries. It is a carbon black-filled compound with mechanical properties designed for improved sealing performance in temperature cycling applications. 7075 has improved thermal resistance that extends maximum service temperature to 327 °C (620 F).

Kalrez® Compounds – 0090

0090 perfluoroelastomer parts deliver durable, reliable sealing solutions for applications requiring excellent rapid gas decompression (RGD) properties as well as high hardness and high modulus properties. Some application areas include downhole equipment such as drilling and completion tools as well as industrial equipment including pumps and valves.

Specialty Kalrez® O-Ring Compounds

Kalrez® Spectrum™ – 7375

Kalrez® Compounds -6380

6380 is a non-black product specifically developed for chemical processes involving hot, aggressive amines. It has also been successfully used in applications involving highly oxidizing chemicals. In addition, it has excellent overall chemical resistance. This cream colored product is easily identifiable when selecting an O-ring material for harsh chemical plant services.

Kalrez® Compounds -7090

7090 is a product for uses requiring higher hardness/higher modulus than more typical applications. Kalrez® 7090 perfluoroelastomer parts are well suited for both static and dynamic applications as well as specific sealing applications requiring extrusion resistance at high temperatures.

Kalrez® Compounds -0040

0040 -is a black product specifically designed for low temperature environments where significant chemical resistance is required. Kalrez® 0040 parts maintain elasticity and seal force at temperatures unattainable by other perfluoroelastomers.

Kalrez® Compound – W240

Kalrez® is a registered trademark of E.I. du Pont de Nemours and Company or its affiliates