Home >> Seal >> O-Rings >> Kalrez® >> Kalrez Spectrum™ 7375

Kalrez® Spectrum™ 7375

For Oxidizing and Reactive Chemical Environment

Table 1: Typical Physical Properties1 |

|

|---|---|

| Color | Black |

| Hardness, Shore A2 | 79 |

| 100% Modulus3 , MPa (psi) | 10.2 (1473) |

| Tensile Strength at Break3 , MPa (psi) | 16.9 (2447) |

| Elongation at Break3 , % | 128 |

| Compression Set4 , % 70 hr at 204 °C (400 °F) | 9 |

| Compression Set4 , % 70 hrs. at 260 °C (500 °F) | 15 |

| Maximum Application Temperature5, °C (ºF) | 300 (572) |

1 Not to be used for specification purposes

2 ASTM D2240 (plied slab test specimens)

3 ASTM D412 (dumbbell test specimens)

4 ASTM D395B & D1414 (AS568 K214 O-ring test specimens)

5 DuPont proprietary test method

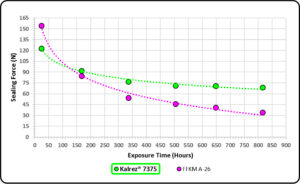

Compression Stress Relaxation (CSR) in Water6 at 225 °C (437 °F), measured at 90 °C (194 °F)

6 O-rings tested by compression stress relaxation per SAE J2979 at 20% compression; Tuckner, Paul, Grace Technology and Development

Table 2: Volume Change (%)7 comparison between different FFKMs after chemical immersion for 672 Hours. Volume swell is a good predictor of performance and low values typically translate to compatibility in the chemical environment.

| Chemical | Temp. ºC (ºF) | Kalrez® Spectrum™7375 | FFKM

Z-1 |

FFKM

A-1 |

FFKM

A-26 |

FFKM

B-3 |

|---|---|---|---|---|---|---|

| Steam | 225(437) | A | C | N/A | A | C |

| Nitric Acid (70%) | 85(185) | A | C | C | B | C |

| Sulfuric Acid (98%) | 150(302) | A | A | C | A | A |

| Butyraldehyde | 70(158) | A | C | B | B | N/A |

| Maleic Anhydride | 100(212) | A | B | N/A | A | A |

| Ammonium Hydroxide | 100(212) | B | B | A | A | A |

Rating system: A: 0–10% volume swell, B: 11–20% volume swell, C: >20% volume swell

N/A = Test Data Not Available.

7 ASTM D471 (AS568 K214 O-ring test specimens)

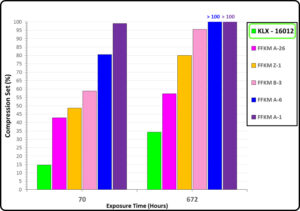

Long-Term Compression Set in Hot Air4,8 at 260 °C (500 °F)

Download the Kalrez® Spectrum™ 7375 technical sheet.

Standard Kalrez® O-Ring Compounds

Kalrez® Compounds – 4079

4079 perfluoroelastomer parts are a black, low compression set product for use in many dry and wet semiconductor process environments. It has excellent chemical resistance, good mechanical properties and outstanding thermal stability.

Kalrez® Compounds – 6375

6375 is designed to give outstanding performance in the widest possible range of chemicals and temperatures. This product is an excellent choice for use in acids, bases, amines, steam, ethylene oxide, and many other aggressive chemicals.

Kalrez® Compounds – 7075

7075 is designed for general-purpose use as O-rings or custom sealing components in the chemical and hydrocarbon processing industries. It is a carbon black-filled compound with mechanical properties designed for improved sealing performance in temperature cycling applications. 7075 has improved thermal resistance that extends maximum service temperature to 327 °C (620 F).

Kalrez® Compounds – 0090

0090 perfluoroelastomer parts deliver durable, reliable sealing solutions for applications requiring excellent rapid gas decompression (RGD) properties as well as high hardness and high modulus properties. Some application areas include downhole equipment such as drilling and completion tools as well as industrial equipment including pumps and valves.

Specialty Kalrez® O-Ring Compounds

Kalrez® Spectrum™ – 7375

Kalrez® Compounds -6380

6380 is a non-black product specifically developed for chemical processes involving hot, aggressive amines. It has also been successfully used in applications involving highly oxidizing chemicals. In addition, it has excellent overall chemical resistance. This cream colored product is easily identifiable when selecting an O-ring material for harsh chemical plant services.

Kalrez® Compounds -7090

7090 is a product for uses requiring higher hardness/higher modulus than more typical applications. Kalrez® 7090 perfluoroelastomer parts are well suited for both static and dynamic applications as well as specific sealing applications requiring extrusion resistance at high temperatures.

Kalrez® Compounds -0040

0040 -is a black product specifically designed for low temperature environments where significant chemical resistance is required. Kalrez® 0040 parts maintain elasticity and seal force at temperatures unattainable by other perfluoroelastomers.

Kalrez® Compound – W240

Kalrez® is a registered trademark of E.I. du Pont de Nemours and Company or its affiliates