Home >> Seal >>O-Rings >> Kalrez O-Rings >> Kalrez Industry Applications >> Chemical Processing Seals

Chemical Processing Seals

Kalrez® seals provide exceptional service in high-heat, aggressive-chemical processing environments. Kalrez® chemical processing seals are a high-performance, cost-effective choice for demanding manufacturing uses. They provide broad chemical resistance and stability up to 327°C, with a range of grades to match specific applications.

| Seal Requirements | Suggested Product |

|---|---|

| Broad Chemical, Steam and Hot Water Resistance, Best General Purpose Product, Max 275°C (527°F) |

Kalrez® Spectrum™ 6375 |

| Resistance to Silanes and Chlorosilanes, Acrylic Monomers, Styrene, Aldehydes, Oxidizing Media, Pure Oxiranes, Max 300°C (572°F) |

Kalrez® Spectrum™ 7275 |

| High Service Temperature, Low Compresstion Set, No Amines or Steam, 7090 has higher hardness |

Kalrez® Spectrum™ 7075 Kalrez® Spectrum™ 7090 |

| Resistance to Oxidizing Media and Hot Amines, Non-black, Max 225°C (437°F) |

Kalrez® Spectrum™ 6380 |

| Low-temperature Applications to -42°C (43°F), Very Good Chemical Resistance |

Kalrez® Spectrum™ 0040 |

A New Standard of Resistance

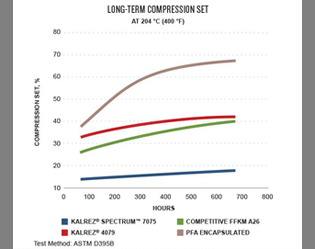

Kalrez® 4079 set the standard for high-temperature, chemically resistant seals with its introduction in the 1980s. It rapidly found its way into aerospace, chemical processing and oil and gas applications. Since its introduction, many additional products have been added to the Kalrez® portfolio, to help meet unique application requirements.

Broad-Spectrum Resistance

Kalrez® Spectrum™ 6375 seals have been an excellent choice for use with acids, bases, amines, steam, ethylene oxide, and many other aggressive chemicals. Mixed streams, once a problem for many chemical processors, are now applying Kalrez® Spectrum™ 6375 parts.

For higher temperature environments, Kalrez® Spectrum™ 7075 seals can withstand temperatures up to 327°C. Kalrez® Spectrum™ 7275, the latest innovative FFKM, provides long life sealing in an array of aggressive chemical environments that are known to be difficult for sealing, including ethylene oxide, acrylic monomers, silanes & chlorosilanes and strong oxidizers such as nitric acid, chlorine and chlorine dioxide, at temperatures up to 300°C.

Kalrez® parts are available in various compounds to meet individual application requirements. Contact Daemar if you require assistance in selecting the appropriate product.

More Efficient Production

Kalrez® chemical processing seals can reduce downtime and extend the mean time between replacements. Some examples of their uses include couplings, pumps, valves, reactors and flange joints. Kalrez® seals have proven performance in mechanical seal applications around the world. Whether you choose O-rings or a customized shape, Kalrez® is a high-value, cost-saving part that you can put to work in your applications.

Industry-Focused Solutions

The application engineers often collaborate with end-users to help users specify products that help meet their application requirements, whether it’s aggressive amines, solvents, high temperatures, or seals designed for specialty applications. Kalrez® seals are used in a range of industries, including:

- Chemical production and transport

- Petroleum refining

- Agricultural chemicals manufacturing

- Painting and coating operations

- Analytical and process control instrumentation

Safety and Compliance Support

Kalrez® seals can help reduce leaks and fugitive emissions, for improved compliance with environmental regulations. Because Kalrez® seals used in chemical processing maintain their sealing integrity within a broad range, they can help maintain operations and lower overall production costs.

Chemical Resistance Guides: Elastomers Chemical Resistance Guide and Kalrez® Application Guide

Chemical Resistance Guide

The Chemical Resistance Guide helps you choose the best elastomer for your application, which has been an industry resource with performance ratings of 20 elastomers in over 1,000 chemicals.

Kalrez® Application Guide

The Kalrez® Application Guide (KAG) helps ensure you choose the best Kalrez® product for your application. The selection tool rates all Kalrez® products in each industry in which Kalrez® is used.

Application temperatures and pressures can be input for more accurate product selection. The KAG can also assist in proper seal design for Kalrez® products in nine standard o-ring groove designs. Lastly, product datasheets are available for all the Kalrez® products.

Features

Standard Kalrez® O-Ring Compounds

Kalrez® Compounds – 4079

4079 perfluoroelastomer parts are a black, low compression set product for use in many dry and wet semiconductor process environments. It has excellent chemical resistance, good mechanical properties and outstanding thermal stability.

Kalrez® Compounds – 6375

6375 is designed to give outstanding performance in the widest possible range of chemicals and temperatures. This product is an excellent choice for use in acids, bases, amines, steam, ethylene oxide, and many other aggressive chemicals.

Kalrez® Compounds – 7075

7075 is designed for general-purpose use as O-rings or custom sealing components in the chemical and hydrocarbon processing industries. It is a carbon black-filled compound with mechanical properties designed for improved sealing performance in temperature cycling applications. 7075 has improved thermal resistance that extends maximum service temperature to 327 °C (620 F).

Kalrez® Compounds – 0090

0090 perfluoroelastomer parts deliver durable, reliable sealing solutions for applications requiring excellent rapid gas decompression (RGD) properties as well as high hardness and high modulus properties. Some application areas include downhole equipment such as drilling and completion tools as well as industrial equipment including pumps and valves.

Specialty Kalrez® O-Ring Compounds

Kalrez® Spectrum™ – 7375

Kalrez® Compounds -6380

6380 is a non-black product specifically developed for chemical processes involving hot, aggressive amines. It has also been successfully used in applications involving highly oxidizing chemicals. In addition, it has excellent overall chemical resistance. This cream colored product is easily identifiable when selecting an O-ring material for harsh chemical plant services.

Kalrez® Compounds -7090

7090 is a product for uses requiring higher hardness/higher modulus than more typical applications. Kalrez® 7090 perfluoroelastomer parts are well suited for both static and dynamic applications as well as specific sealing applications requiring extrusion resistance at high temperatures.

Kalrez® Compounds -0040

0040 -is a black product specifically designed for low temperature environments where significant chemical resistance is required. Kalrez® 0040 parts maintain elasticity and seal force at temperatures unattainable by other perfluoroelastomers.

Kalrez® Compound – W240

Kalrez® is a registered trademark of E.I. du Pont de Nemours and Company or its affiliates