Home >> Seal >>O-Rings >> Kalrez O-Rings >> Kalrez Case Studies >> Sealing Collaboration Pays Dividends in Chamber Cleaning

Sealing Collaboration Pays Dividends in Chamber Cleaning

The Challenge

In the very competitive environment of semiconductor chip manufacturing, reduced cost per wafer is a top priority. DuPont successfully collaborated with Spansion Inc. Fab 25 in Austin, Texas to evaluate an O-ring product designed to help increase the uptime of HDPCVD equipment operating under aggressive chamber cleaning plasma conditions.

The dramatic improvement in seal performance enabled Spansion to make a step change in their preventative maintenance (PM) schedule that resulted in increased productivity and reduced cost-of-ownership. Spansion is the largest provider of Flash memory solutions in the world for the integrated electronics market.

The Solution

For Roger Sorum, equipment engineer at Spansion Fab 25, uptime and quality are his primary responsibilities to help maintain a competitive advantage. A problem occurred in the HDPCVD equipment when process gases (SiH4, O2, He) and chamber cleaning plasma (two stage NF3 and O2 plasma) created an aggressive process environment. High particle count and leaks from seal erosion and compression set caused sealing issues in IMD and STI processes. The scheduled PM cycle was 90 days, but premature sealing issues occurred within 30–60 days with the isolation valve poppet seal, slit valve door seal and the MESC port flange insert seal. The incumbent O-ring performance issues were related to physical as well as chemical plasma attack creating seal erosion.

Replacing O-rings can take up to 12 hours to bring the machine back on line and pass wafer qualification. Some seal locations limit individual chamber production, while others limit the entire tool. “The challenge is to increase availability while reducing the total cost-of-ownership” says Sorum.

Spansion turned to DuPont for options to produce longer seal life with reduced particle generation. Within several months, DuPont developed a prototype.

After reviewing test results, parts were produced for trials against other competitive FFKM products. Kalrez® 9100 parts outperformed the competitive FFKM products under all conditions. The DuPont and Spansion team, working together, pushed Kalrez® 9100 parts to extreme parameters faster than anyone expected and contributed to the success of this process.

Key Advantages

Key learnings from the collaboration were the following:

- Active feedback during development in real time;

- Testing Kalrez® 9100 parts in the harshest possible conditions;

- Extending testing well beyond timeframes for planned maintenance to establish a new, far-reaching standard for PM limits, all with Spansion process engineering agreement. Currently, Kalrez® 9100 continues to exceed the normal Spansion PM schedule by up to 6 times longer, extending the 30-day PM out to 180 days, depending upon the seal location. Increased equipment availability has increased the fab production capacity by more than 20%, without the need to purchase and install additional equipment. Spansion has now expanded their adoption of Kalrez® 9100 to other tools in both thin films and dry etch with consistently favorable results.

Features

Standard Kalrez® O-Ring Compounds

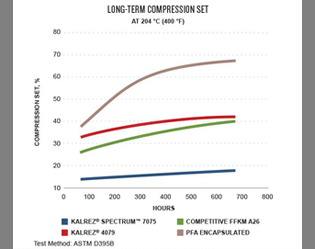

Kalrez® Compounds – 4079

4079 perfluoroelastomer parts are a black, low compression set product for use in many dry and wet semiconductor process environments. It has excellent chemical resistance, good mechanical properties and outstanding thermal stability.

Kalrez® Compounds – 6375

6375 is designed to give outstanding performance in the widest possible range of chemicals and temperatures. This product is an excellent choice for use in acids, bases, amines, steam, ethylene oxide, and many other aggressive chemicals.

Kalrez® Compounds – 7075

7075 is designed for general-purpose use as O-rings or custom sealing components in the chemical and hydrocarbon processing industries. It is a carbon black-filled compound with mechanical properties designed for improved sealing performance in temperature cycling applications. 7075 has improved thermal resistance that extends maximum service temperature to 327 °C (620 F).

Kalrez® Compounds – 0090

0090 perfluoroelastomer parts deliver durable, reliable sealing solutions for applications requiring excellent rapid gas decompression (RGD) properties as well as high hardness and high modulus properties. Some application areas include downhole equipment such as drilling and completion tools as well as industrial equipment including pumps and valves.

Specialty Kalrez® O-Ring Compounds

Kalrez® Spectrum™ – 7375

Kalrez® Compounds -6380

6380 is a non-black product specifically developed for chemical processes involving hot, aggressive amines. It has also been successfully used in applications involving highly oxidizing chemicals. In addition, it has excellent overall chemical resistance. This cream colored product is easily identifiable when selecting an O-ring material for harsh chemical plant services.

Kalrez® Compounds -7090

7090 is a product for uses requiring higher hardness/higher modulus than more typical applications. Kalrez® 7090 perfluoroelastomer parts are well suited for both static and dynamic applications as well as specific sealing applications requiring extrusion resistance at high temperatures.

Kalrez® Compounds -0040

0040 -is a black product specifically designed for low temperature environments where significant chemical resistance is required. Kalrez® 0040 parts maintain elasticity and seal force at temperatures unattainable by other perfluoroelastomers.

Kalrez® Compound – W240

Kalrez® is a registered trademark of E.I. du Pont de Nemours and Company or its affiliates