Home >> Seal >> Trelleborg Sealing Solution >> Turcon® Variseal®

Turcon® Variseal®

Variseal® are effective in a wide range of applications. They are chosen when higher resistance to chemical media is required, if the seal is required to operate in extremes of temperature and/or where good extrusion and compression characteristics are needed.

Method Of Operation

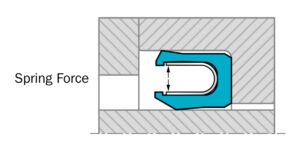

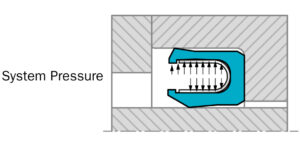

All Variseal® designs included on this page have the same operating principle and differ only in their profile form and the type of metallic spring used.

The Variseal® spring supplies the load required for sealing at low pressures (Figure 1). The “U” shaped jacket allows fluid pressure to energize the sealing lips, so total sealing pressure rises with increasing operating pressure (Figure 2).

Performance

Learn More with Additional Resources

- Choosing the Right Seal for your Application

- Seal Materials

- Spring Types and Materials

- Quality Criteria

- Hardware Design Considerations & Basic Gland Types

- Preventing Seal Damage

Industry Applications

Turcon® Variseal® in Semiconductor Industry

Field-proven in extreme gas and liquid handling situations, a number of variations of Turcon® Variseal® spring-energized seals are especially suited to the most demanding of semiconductor sealing applications, including high vacuum and corrosive environments.

Download Trelleborg’s Turcon® Variseal® Catalogue.

Turcon® Variseal® designs have three main characteristics:

Turcon® Variseal® designs have three main characteristics: