Home >> Seal >> Trelleborg Sealing Solution >> Turcon® Variseal® >> Spring Types and Materials

Spring Types and Materials

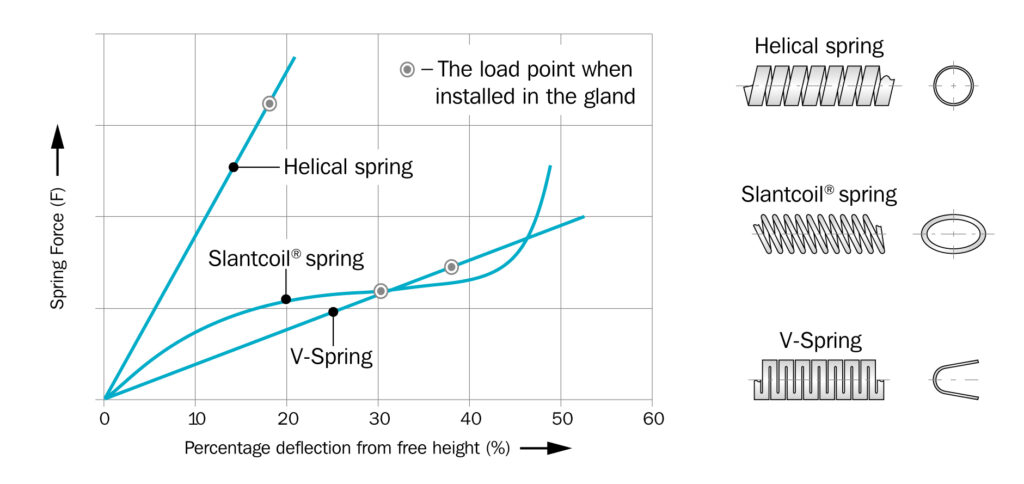

A metal spring is incorporated into Turcon ® Variseal ® to provide elasticity to the seal. This makes the seal permanently elastic, despite changes in operating temperature, pressure or chemicals processed. Each of the three spring types used in Variseal ® has unique properties that give them their performance characteristics. The two most important properties of the spring, besides the corrosion resistance of the metal, are load value and deflection range. The spring load affects sealing ability, friction and the wear rate of the seal. The deflection range determines the ability of the Variseal ® designs to take up wear and compensate for variations in gland dimensions.

V-Spring

V-Spring is the standard spring type for Variseal ® M2, Variseal M2S and Roto Variseal ®. It operates as a set of “cantilever beams”, extending from an arc at the bottom of the spring. The shape of the spring causes the load to be focused on the front edge of the sealing lip, giving the seal a positive wiping action. The V-Spring has a moderate load and deflection range.

Helical Spring

The Helical spring, used in Variseal ® H and Variseal ® HF, is made from a flat strip formed into a helical coil spring. It has a much higher unit load and a shorter deflection range than the other spring types. Therefore, it is best suited to static or slow dynamic applications, where friction and wear are not the key issues. Variseal ® H and Variseal ® HF are the best choices for vacuum, gas and low-temperature applications.

Slantcoil ® Spring

The Slantcoil ® spring used in Variseal ® W2 consists of round wire formed into slanted coils and has a relatively constant load over a wide deflection range. This allows accurate control of friction during the working life of the seal. Its unique design makes it almost impossible to damage the spring by excessive deformation of the seal.

Spring Materials

The standard spring material for Turcon ® Variseal ® is stainless steel (spring code S). Two further materials are available for specific applications, as detailed in the table below.

Table: Spring Materials Selection Guide

| Media | Spring materials | Spring order code |

| For General use e.g. Oil Grease Air Water, steam Solvents Food, drugs Gas |

Stainless steel DIN Mat No. 1.4310/1.4319 AISI 301/302 UNS 30100 |

S (Standard spring material) |

| For use in corrosive media e.g. Acids Caustics Seawater |

Hastelloy ® C-276 DIN Mat No. 2.4819 UNS N10276 |

H |

| For petrochemical use e.g. Crude oil Sour gas |

Elgiloy ® 1) DIN Mat No. 2.4711 UNSR30003 |

E |

Hastelloy® is a registered trademark of Haynes International, Inc. Elgiloy® is a registered trademark of the Elgiloy® Specialty Metals Alternative brand may be used.

1) NACE-approval