Home >> Seal >> Trelleborg Sealing Solution >> Turcon® Variseal® >> Preventing Seal Damage

Preventing Seal Damage

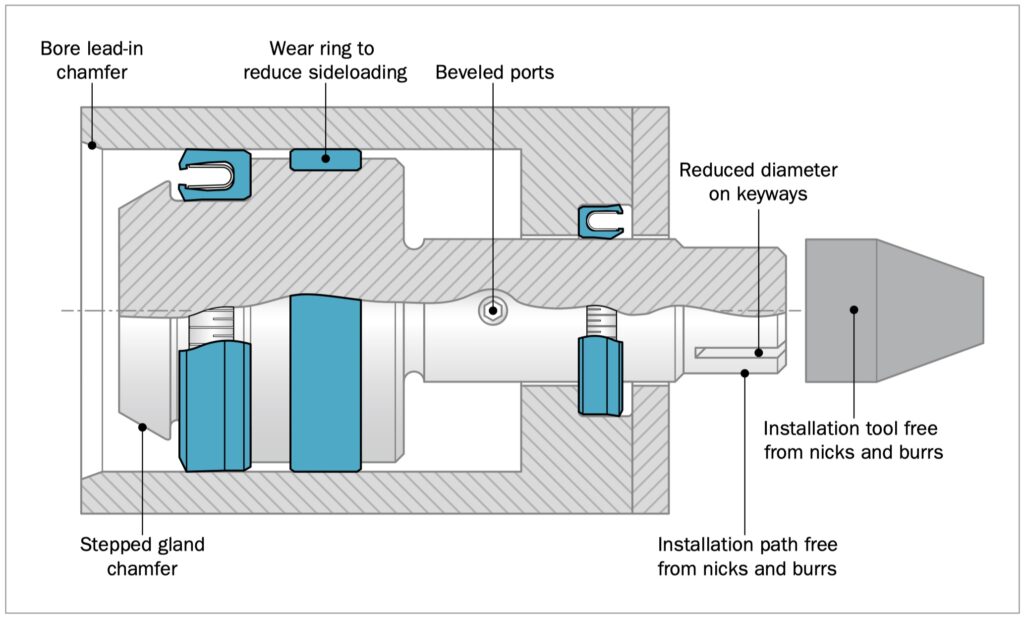

Taking a few reasonable precautions to prevent scratching the seals will increase seal life and reliability. To prevent damage during installation, consider the following aspects of hardware design:

- The installation path should be kept free of nicks, burrs, scratches, or any sharp edge that could damage the seal.

- Any tool used to install seals should be free of sharp edges. Screw drivers are especially notorious for damaging seals and should not be used to handle the Variseal®.

- A lead-in chamfer on the end of the rod or bore helps during installation. The proper chamfer dimensions are given in the Groove Design section. This is especially important where seals are to be installed face first (spring cavity side first) into the gland.

- When seals must be installed across ports, bevel and smooth the edges of the ports.

- Designate splines or keyways to fall on a smaller diameter than the sealing surface or use a protective sleeve to cover them during installation as illustrated in Figure below.

- The Variseal® is typically installed without the aid of heat or lubrication. In situations where heat is required to soften and expand the seal, submerse them for a few minutes in very hot oil or water.

- Application of a lubricant to surfaces of the seal and hardware reduces the force required to push the seal into a difficult gland such as a solid O-Ring groove.

- During handling, place the seals where they will not be crushed by tools or other items. It is advisable to leave the seals in their shipping containers until just before installation.

- Avoid glands which require bending the seals during installation. When seals must be stretched or compressed into a difficult gland, be sure to use the recommended tooling to resize the seals.

- Do not sideload the seals any more than is necessary. Avoid gland situations where a heavy rod or piston rests against one side of the seal.

If you feel that your application poses an especially difficult problem with installation, contact your local Customer Solution Center.