Home >> Seal >>O-Rings >> Kalrez O-Rings >> Kalrez Case Studies >> Kalrez® O-rings for Hydrogen Sulfide Removal

Kalrez® O-rings for Hydrogen Sulfide Removal

Amine treatment is a process typically used for Hydrogen Sulfide removal from natural gas (sour gas). This operation is commonly referred to as gas “sweetening”.

Amine units are used all over the world in oil refineries and gas plants to remove hydrogen sulfide (H2S) from a product stream. New environmental standards are stricter and require ever decreasing contents of H2S in clean natural gas. Most of the new sources of oil and gas discovered today have high contents of H2S which demand more efficient removal technologies (the Shah Gas field in the United Arab Emirates for example has up to 30% H2S).

The Challenge

Amine units operate under harsh chemical environments. H2S for example, needs to be handled with care and can cause embrittlement of metal equipment. These processes also operate at high temperature where perfluoroelastomer sealing components are required. Amines, however, are known to be aggressive to many FFKMs. When elastomers are in contact with amines, they tend to swell to a high degree which results in a loss of mechanical properties and extrusion. This can lead to leakage, rupture of the fluid film in mechanical seals due to face seal deformation and an increase in torque needed to operate.

The Solution

DuPont™ Kalrez® Spectrum™ 6380 perfluoroelastomer parts offer outstanding resistance to amines because it exhibits four times lower swell over general purpose perfluoroelastomer (FFKM) offerings.

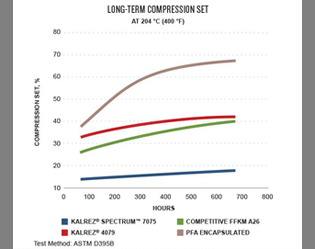

The use of DuPont™ Kalrez® Spectrum™ 6380 parts in these applications may extend the MTBR (Mean Time Between Repairs) of valves and pump mechanical seals and reduce leakage which can help contribute to reduce maintenance costs and lower emissions. The latest Kalrez® 0090 parts represent another option for this application when high pressure resistance is needed. The following graph compares the chemical resistance of Kalrez® Spectrum™ 6380 to other sealing materials when exposed to a typical amine/water mixture used in gas sweetening units.

Features

Standard Kalrez® O-Ring Compounds

Kalrez® Compounds – 4079

4079 perfluoroelastomer parts are a black, low compression set product for use in many dry and wet semiconductor process environments. It has excellent chemical resistance, good mechanical properties and outstanding thermal stability.

Kalrez® Compounds – 6375

6375 is designed to give outstanding performance in the widest possible range of chemicals and temperatures. This product is an excellent choice for use in acids, bases, amines, steam, ethylene oxide, and many other aggressive chemicals.

Kalrez® Compounds – 7075

7075 is designed for general-purpose use as O-rings or custom sealing components in the chemical and hydrocarbon processing industries. It is a carbon black-filled compound with mechanical properties designed for improved sealing performance in temperature cycling applications. 7075 has improved thermal resistance that extends maximum service temperature to 327 °C (620 F).

Kalrez® Compounds – 0090

0090 perfluoroelastomer parts deliver durable, reliable sealing solutions for applications requiring excellent rapid gas decompression (RGD) properties as well as high hardness and high modulus properties. Some application areas include downhole equipment such as drilling and completion tools as well as industrial equipment including pumps and valves.

Specialty Kalrez® O-Ring Compounds

Kalrez® Spectrum™ – 7375

Kalrez® Compounds -6380

6380 is a non-black product specifically developed for chemical processes involving hot, aggressive amines. It has also been successfully used in applications involving highly oxidizing chemicals. In addition, it has excellent overall chemical resistance. This cream colored product is easily identifiable when selecting an O-ring material for harsh chemical plant services.

Kalrez® Compounds -7090

7090 is a product for uses requiring higher hardness/higher modulus than more typical applications. Kalrez® 7090 perfluoroelastomer parts are well suited for both static and dynamic applications as well as specific sealing applications requiring extrusion resistance at high temperatures.

Kalrez® Compounds -0040

0040 -is a black product specifically designed for low temperature environments where significant chemical resistance is required. Kalrez® 0040 parts maintain elasticity and seal force at temperatures unattainable by other perfluoroelastomers.

Kalrez® Compound – W240

Kalrez® is a registered trademark of E.I. du Pont de Nemours and Company or its affiliates