Home >> Seal >>O-Rings >> Kalrez O-Rings >> Kalrez Case Studies >> Kalrez® KVSP™ valve stem packing saves 56.000 £

Kalrez® KVSP™ valve stem packing saves 56.000 £

Following trials of alternative valve stem packing materials, BP Chemicals Limited significantly reduced unscheduled reactor shutdowns and saved an estimated 56.000 £ annually for each reactor control valve at its Hull, UK, plant by switching from PTFE packing to DuPont™ Kalrez® Valve Stem Packings (KVSP™). In addition to environmental and safety benefits due to improved leak prevention, the company reports much improved valve hysterisis and control, less “sticktion”, and longer service life for valve stem and bore parts.

The Kalrez® Valve Stem Packing set, supplied and fitted by Authorized Kalrez® Distributor James Walker & Co. Ltd, operates in an aggressive process environment involving 60 per cent pentane and 40 per cent butane, hexane, acetone and water acid at –30 °C (-22°F), at a specific pressure. These conditions caused annual attention to the previously fitted PTFE packings in order to prevent leakage, damage to valve parts and unscheduled reactor shutdowns.

The Challenge

“In the past, preventing product leakage from valve glands on the separator four levels at the company’s DF3 plant in order to avoid outages into the atmosphere and surrounding area was a major effort,” said Ken Foster, Line Manager Maintenance Services – Control Valve Department, BP Chemicals, Hull. “Also, valve stems became damaged beyond repair, necessitating costly replacement.”

Each time a valve has to be overhauled, whether scheduled or unscheduled, it is recorded on the valve history. The valves in question had been overhauled at least once per year over the past ten years.

The Solution

Previous attempts to remedy the problem with varying packing configurations and chromed stems were not successful. The solution was to fit a Kalrez® KVSP™ set supplied by James Walker & Co. Ltd, in conjunction with a ceramic coated stem.

DuPont™ Kalrez® Valve Stem Packing is recognized as the leading packing-based solution to help reduce fugitive air emissions and valve leakage in chemical and petroleum manufacturing processes. The systems have been used successfully in hundreds of different chemicals including benzene, vinyl chloride, chlorine, fluorine, steam, hot water and heat transfer fluids.

“At BP Chemicals we estimate that an unscheduled shutdown due to a valve leak can cost the plant as much as 56.000 £ annually per reactor. With four reactors, possible annual savings by converting to KVSP at this plant could total approximately 225.000 £,” Foster adds.

Features

Standard Kalrez® O-Ring Compounds

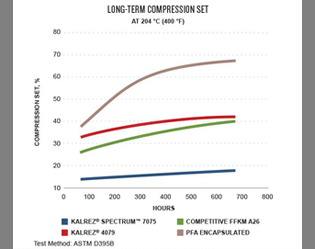

Kalrez® Compounds – 4079

4079 perfluoroelastomer parts are a black, low compression set product for use in many dry and wet semiconductor process environments. It has excellent chemical resistance, good mechanical properties and outstanding thermal stability.

Kalrez® Compounds – 6375

6375 is designed to give outstanding performance in the widest possible range of chemicals and temperatures. This product is an excellent choice for use in acids, bases, amines, steam, ethylene oxide, and many other aggressive chemicals.

Kalrez® Compounds – 7075

7075 is designed for general-purpose use as O-rings or custom sealing components in the chemical and hydrocarbon processing industries. It is a carbon black-filled compound with mechanical properties designed for improved sealing performance in temperature cycling applications. 7075 has improved thermal resistance that extends maximum service temperature to 327 °C (620 F).

Kalrez® Compounds – 0090

0090 perfluoroelastomer parts deliver durable, reliable sealing solutions for applications requiring excellent rapid gas decompression (RGD) properties as well as high hardness and high modulus properties. Some application areas include downhole equipment such as drilling and completion tools as well as industrial equipment including pumps and valves.

Specialty Kalrez® O-Ring Compounds

Kalrez® Spectrum™ – 7375

Kalrez® Compounds -6380

6380 is a non-black product specifically developed for chemical processes involving hot, aggressive amines. It has also been successfully used in applications involving highly oxidizing chemicals. In addition, it has excellent overall chemical resistance. This cream colored product is easily identifiable when selecting an O-ring material for harsh chemical plant services.

Kalrez® Compounds -7090

7090 is a product for uses requiring higher hardness/higher modulus than more typical applications. Kalrez® 7090 perfluoroelastomer parts are well suited for both static and dynamic applications as well as specific sealing applications requiring extrusion resistance at high temperatures.

Kalrez® Compounds -0040

0040 -is a black product specifically designed for low temperature environments where significant chemical resistance is required. Kalrez® 0040 parts maintain elasticity and seal force at temperatures unattainable by other perfluoroelastomers.

Kalrez® Compound – W240