Home >> Blog >> Extending Seal Life Starts with Proper Selection

Extending Seal Life Starts with Proper Selection

Although not often the most expensive component in a bearing assembly the proper selection of the radial shaft seal can be crucial to ensuring bearing longevity and reducing system maintenance costs of gear boxes, pumps, motors and other power transmission devices.

Rotary shaft seals have two primary functions; the first is to retain system lubricants and therefore allowing for proper operation with optimal levels of lubrication. The seal’s second primary function is to exclude contaminants from entering the system, if allowed to enter the contaminants will eventually cause the bearings to fail.

Assessing the Operating Environment

Proper seal selection begins by understanding and assessing the demands of the operating environment of the particular application. The key factors to consider are:

- Operating temperature for the seal

- Pressure (typically between 3 and 7 psi for rotary shaft seals)

- Fluid Compatibility with the lubricant and the process fluid

- Type of shaft motion (constant, intermittent)

- Shaft Eccentricity (shaft-to-bore misalignment, dynamic run-out)

- Shaft surface speed

- Contaminants in the operating environment

- Geometry of the Shaft and housing bore (lead-in chamfers, dimensions and tolerances)

- Shaft hardness and surface finish

Component Material and Design

To successfully achieving its intended goal the shaft seal must create a seal between either i) a rotary component and a stationary component or ii) between components in relative motion.

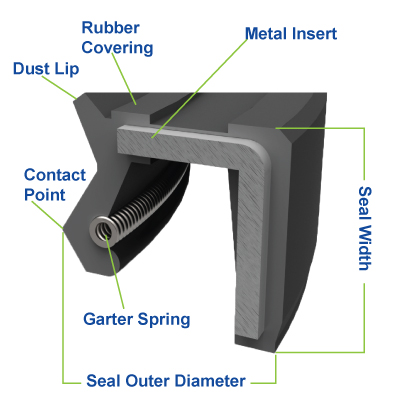

After completing the operating environment assessment the specifications for the individual elements of the seal are determined based on the application data. Each of the seal’s components have a role to play in the overall performance of the seal;

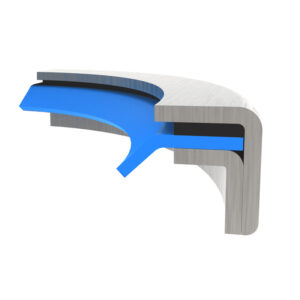

- The Casing provides structure and rigidity and creates a static seal with the bore, typically constructed of carbon steel (may or may not be rubber covered) and press fits into the housing bore. There are many variations of casing designs depending on the specific geometric requirements of the application.

- The Sealing Lip and the garter spring (design dependent) maintain a dynamic seal with the shaft. Based on the operating environment assessment the most compatible elastomer is selected. The spring and the geometry of the lip help preload the lip on the shaft, as the shaft starts rotating a thin layer of media (.00015”) forms between the shaft and the lip contact point. This reduces friction between the shaft and the sealing lip and helps minimize shaft wear.

Once the correct seal is selected it is important to familiarize yourself with the proper seal installation procedures as they can help reduce future seal failures (refer to our article Sealed Right, Sealed Tight). To aid in installation the shaft and bore should each have lead in chamfers and be free from sharp edges and burrs.