Home >> Blog >> Achieving Peak Performance with High-Pressure PTFE Seals

Achieving Peak Performance with High-Pressure PTFE Seals

In today’s industrial landscape, where machinery operates under increasingly demanding conditions, the importance of reliable sealing solutions cannot be overstated. High-pressure and extreme temperatures can wreak havoc on equipment if not adequately protected. This is where High-Pressure PTFE Seals step in, offering a robust, high-performance solution engineered for extreme conditions.

Engineered for Excellence

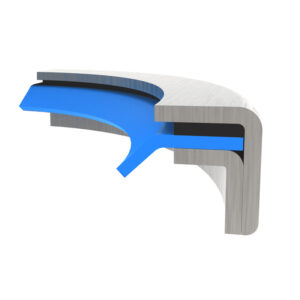

DMR High-Pressure PTFE Seals are purpose-built to thrive in the most challenging environments. They feature PTFE Sealing Lip and are Metallic Spring-Free. For demanding situations, we can even make the casings in stainless steel. These seals are designed to excel in the face of extreme temperatures, high pressures, high speeds, corrosive liquids & gases and more.

- Chemical Inertness: PTFE is highly resistant to a wide range of chemicals, acids, and bases, making it suitable for use in aggressive environments.

- Low Friction: PTFE has an extremely low coefficient of friction, which reduces wear and ensures smooth operation, especially in high-pressure dynamic applications.

- High Temperature Resistance: PTFE can withstand extreme temperatures, ranging from cryogenic conditions to over 482°F (250°C), without losing its sealing capabilities.

- Excellent Insulation Properties: PTFE is an excellent electrical insulator, which makes it suitable for sealing in electrical and high-voltage applications.

- Non-Stick Surface: PTFE’s non-stick surface properties make it easy to clean and prevent buildup of contaminants.

- High-Speed Operations: Operating at high speeds of up to 45 m/s, these seals maintain their integrity and effectiveness.

Applications of High-Pressure PTFE Seals

High-pressure PTFE seals find applications in a variety of industries where reliable sealing is essential, including:

- Oil and Gas: PTFE seals are used in valves, pumps, and pipelines to prevent leaks and maintain the integrity of high-pressure systems in the oil and gas industry.

- Aerospace: Aircraft and spacecraft require seals that can withstand extreme temperatures and pressures. PTFE seals are used in critical components such as hydraulic systems and fuel pumps.

- Chemical Processing: PTFE seals are a go-to choice in the chemical industry, ensuring the containment of aggressive chemicals in pumps, valves, and reactors.

- Pharmaceuticals: High-pressure PTFE seals are utilized in pharmaceutical manufacturing equipment, where cleanliness and chemical resistance are paramount.

- Food and Beverage: In the food and beverage industry, PTFE seals are used in high-pressure homogenizers and pumps for processing and packaging.

Benefits of High-Performance PTFE Seals

When implemented correctly, high-pressure PTFE seals offer several benefits:

- Reduced Downtime: Reliable sealing minimizes the risk of leaks and equipment failure, reducing costly downtime for maintenance and repairs.

- Increased Efficiency: PTFE’s low friction properties reduce energy consumption in high-pressure systems, improving overall efficiency.

- Extended Equipment Lifespan: PTFE seals can significantly extend the lifespan of components and equipment, resulting in a better return on investment.

- Enhanced Safety: In industries dealing with hazardous materials, PTFE seals contribute to safety by preventing leaks and releases.

High-pressure PTFE seals are a testament to the remarkable properties of this versatile material. Their ability to maintain integrity and perform under extreme conditions makes them indispensable in various industries. When designing systems for high-pressure applications, investing in quality PTFE seals is a wise choice to ensure peak performance, reliability, and safety. With the right material selection and design considerations, these seals can truly shine in the harshest environments, demonstrating their worth in high-performance applications.

So, whether you’re in the market for seals that can handle the toughest conditions in pumps, agitators, blowers, compressors, mixers, or any other industrial equipment, our High-Pressure PTFE Seals are your go-to solution. Invest in durability, reliability, and performance – invest in High-Pressure PTFE Seals. Please don’t hesitate to contact your local Daemar sales representative if you have any questions.