Home >> Seal >>O-Rings >> Kalrez O-Rings >> Kalrez Case Studies >> Kalrez® Parts Extend Service Life for Process Instrument

Kalrez® Parts Extend Service Life for Process Instrument

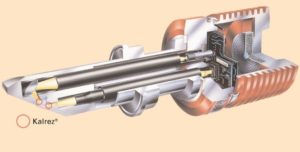

Delicate digital detector circuits and fibre optics in the sensor head of K-Patents’“PR-01-S” process refractometer are sealed from attack by aggressive process media, temperatures from –20 ° to +220 °C, and pressures from –0,7 to +25 bar, by two DuPont™ Kalrez® gaskets situated either side of the vital Spinel prism.

The Challenge

By switching from gasket seals of PTFE to custom gaskets of DuPont™ Kalrez® perfluoroelastomer parts in the sensor head of a process instrument refractometer used by the food, pulp and paper and chemical industries, process instrument manufacturer K-Patents Oy, Vantaa, Finland, was able to dramatically extend instrument service life, increase reliability and safety, and reduce costs for the company and its customers.

The Solution

Aggressive environment

Through permanent in-line fluids immersion, K-Patents’ “PR-01-S” refractometer is exposed to temperatures from –20 ° to +220 °C, pressures from –0,7 to +25 bar, and some 500 process fluids and chemicals, many of which are extremely aggressive. Delicate digital detector circuits and fiber optics in the sensor head are sealed by two gaskets from attack by aggressive fluids. Because of inherent inelasticity, the original PTFE gaskets could not withstand the dynamic temperature fluctuations of many food, pulp and paper and chemical manufacturing processes, creating a leak path allowing process media to enter and damage the device. As a result, costly replacement of the PTFE seal became necessary approximately every 6–12 months.

Key Advantages

No leakage in 10 years with DuPont™ Kalrez®

Esko Kamrat, Design Engineer at K-Patents, decided to replace the PTFE seals with gaskets of Kalrez®. He reports that, due to its elasticity and outstanding chemical and heat resistance, the perfluoroelastomer is now achieving as much as 10 years service life without leakage. Frequency of costly repair of the “PR-01-S” refractometer has also been much reduced. Kalrez® perfluoroelastomer parts have provided superior performance in a wide variety of demanding sealing applications. Kalrez® resists more than 1800 chemicals and is thermally stable up to 327 °C.

Features

Standard Kalrez® O-Ring Compounds

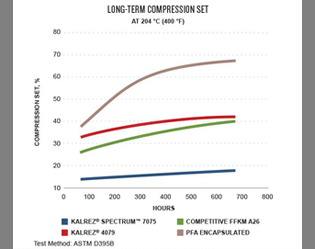

Kalrez® Compounds – 4079

4079 perfluoroelastomer parts are a black, low compression set product for use in many dry and wet semiconductor process environments. It has excellent chemical resistance, good mechanical properties and outstanding thermal stability.

Kalrez® Compounds – 6375

6375 is designed to give outstanding performance in the widest possible range of chemicals and temperatures. This product is an excellent choice for use in acids, bases, amines, steam, ethylene oxide, and many other aggressive chemicals.

Kalrez® Compounds – 7075

7075 is designed for general-purpose use as O-rings or custom sealing components in the chemical and hydrocarbon processing industries. It is a carbon black-filled compound with mechanical properties designed for improved sealing performance in temperature cycling applications. 7075 has improved thermal resistance that extends maximum service temperature to 327 °C (620 F).

Kalrez® Compounds – 0090

0090 perfluoroelastomer parts deliver durable, reliable sealing solutions for applications requiring excellent rapid gas decompression (RGD) properties as well as high hardness and high modulus properties. Some application areas include downhole equipment such as drilling and completion tools as well as industrial equipment including pumps and valves.

Specialty Kalrez® O-Ring Compounds

Kalrez® Spectrum™ – 7375

Kalrez® Compounds -6380

6380 is a non-black product specifically developed for chemical processes involving hot, aggressive amines. It has also been successfully used in applications involving highly oxidizing chemicals. In addition, it has excellent overall chemical resistance. This cream colored product is easily identifiable when selecting an O-ring material for harsh chemical plant services.

Kalrez® Compounds -7090

7090 is a product for uses requiring higher hardness/higher modulus than more typical applications. Kalrez® 7090 perfluoroelastomer parts are well suited for both static and dynamic applications as well as specific sealing applications requiring extrusion resistance at high temperatures.

Kalrez® Compounds -0040

0040 -is a black product specifically designed for low temperature environments where significant chemical resistance is required. Kalrez® 0040 parts maintain elasticity and seal force at temperatures unattainable by other perfluoroelastomers.

Kalrez® Compound – W240

Kalrez® is a registered trademark of E.I. du Pont de Nemours and Company or its affiliates