Home >> Seal >>O-Rings >> Kalrez O-Rings >> Kalrez Case Studies >> Pharmaceutical Seals for CIP and SIP

Pharmaceutical Seals for CIP and SIP

Clean in Place Service benefits from Kalrez® O-rings

Hilge-Pumpen AG, Swiss subsidiary of Philipp-Hilge GmbH, Bodenheim, Germany, selected Kalrez® 6221 perfluoroelastomer parts to seal its Euro-Hygia®, Hygiana-HT and Contra pump series, to meet the stringent safety, cleanliness and sterilization requirements demanded by the pharmaceutical, biotechnology and cosmetics industries.

The Challenge

Pumps used in pharmaceutical, biotechnological and sterile processes are subject to some of the highest standards and safety requirements worldwide. In addition to ease of operation they must also provide maximum biological safety without any unfavorable hydraulic characteristics that could adversely influence sensitive products.

Strict compliance is required with standards set by the FDA, GMP and 3A-Sanitary. In Europe the draft “DIN EN 12462 Biotechnology” sets out performance criteria for pumps in terms of cleanability and sterilization, leakage, materials and their surfaces, and design details in relation to CIP (clean in place) and SIP (sterilization in place) capabilities.

Specific attention must also be paid to the surface roughness of pump construction materials in order to reduce bacterial growth to an absolute minimum and facilitate cleaning processes. Stainless steel used in the pump is therefore carefully selected and electrochemically finished to achieve a smooth, almost particle-free surface.

Pump and process engineers must therefore take special care in selecting appropriate sealing materials. In addition to hygienic installation and production requirements, they must consider:

- Expected sealing life

- Chemical resistance

- CIP and SIP capabilities FDA compliance status.

The Solution

In view of the demanding purity and performance criteria, Hilge-Pumpen AG selected Kalrez® O-rings to for its Euro-Hygia®, Hygiana-HT and Contra pump to meet the rigorous safety requirements of the pharmaceutical, biotechnology and cosmetics industries.

DuPont™ Kalrez® 6221 perfluoroelastomer parts comply with FDA requirements for repeated use in food contact with extractable levels below 0.2 milligrams per square inch, and meet stringent requirements for pharmaceutical and high-purity chemical applications.

The perfluoroelastomer parts are specified to reduce the risk of leakage of chemicals and ultra-pure water used, for example, during CIP and SIP procedures at temperatures up to 160 °C. Kalrez® parts combine the outstanding sealing properties of a perfluoroelastomer with the attributes of PTFE to help provide an effective solution for processes requiring minimal contamination, as well as longer sealing life.

Key Advantages

The surface finish of Kalrez® parts works in harmony with the stainless steel to help provide an optimum sealing environment for reduced contamination. This is aided by the low extractable levels of Kalrez® seals measured in various chemical environments — similar to those of PTFE.

Features

Standard Kalrez® O-Ring Compounds

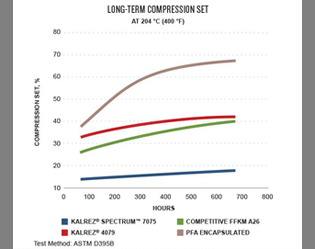

Kalrez® Compounds – 4079

4079 perfluoroelastomer parts are a black, low compression set product for use in many dry and wet semiconductor process environments. It has excellent chemical resistance, good mechanical properties and outstanding thermal stability.

Kalrez® Compounds – 6375

6375 is designed to give outstanding performance in the widest possible range of chemicals and temperatures. This product is an excellent choice for use in acids, bases, amines, steam, ethylene oxide, and many other aggressive chemicals.

Kalrez® Compounds – 7075

7075 is designed for general-purpose use as O-rings or custom sealing components in the chemical and hydrocarbon processing industries. It is a carbon black-filled compound with mechanical properties designed for improved sealing performance in temperature cycling applications. 7075 has improved thermal resistance that extends maximum service temperature to 327 °C (620 F).

Kalrez® Compounds – 0090

0090 perfluoroelastomer parts deliver durable, reliable sealing solutions for applications requiring excellent rapid gas decompression (RGD) properties as well as high hardness and high modulus properties. Some application areas include downhole equipment such as drilling and completion tools as well as industrial equipment including pumps and valves.

Specialty Kalrez® O-Ring Compounds

Kalrez® Spectrum™ – 7375

Kalrez® Compounds -6380

6380 is a non-black product specifically developed for chemical processes involving hot, aggressive amines. It has also been successfully used in applications involving highly oxidizing chemicals. In addition, it has excellent overall chemical resistance. This cream colored product is easily identifiable when selecting an O-ring material for harsh chemical plant services.

Kalrez® Compounds -7090

7090 is a product for uses requiring higher hardness/higher modulus than more typical applications. Kalrez® 7090 perfluoroelastomer parts are well suited for both static and dynamic applications as well as specific sealing applications requiring extrusion resistance at high temperatures.

Kalrez® Compounds -0040

0040 -is a black product specifically designed for low temperature environments where significant chemical resistance is required. Kalrez® 0040 parts maintain elasticity and seal force at temperatures unattainable by other perfluoroelastomers.

Kalrez® Compound – W240

Kalrez® is a registered trademark of E.I. du Pont de Nemours and Company or its affiliates