Home >> Seal >>O-Rings >> Kalrez O-Rings >> Kalrez Case Studies >> Kalrez® Spectrum™ 6380 Offers Amine Resistance to Improve MTBR

Kalrez® Spectrum™ 6380 Offers Amine Resistance to Improve MTBR

A major chemical company switched to DuPont™ Kalrez® Spectrum™ 6380 perfluoroelastomer parts for amine resistance and increased mean time between repairs (MTBR). MTBR improved 3x in a mechanical seal for hot, aggressive amines.

The Challenge

A.W. Chesterton was challenged to improve the mean time between repairs (MTBR) in a mechanical seal for a hot, primary amine service at a major chemical facility in Texas. Realizing that elastomer performance was a critical component in improving seal lifetime, A.W. Chesterton contacted DuPont to provide a technologically advanced O-ring solution.

The Solution

Hot, primary amines are extremely aggressive towards elastomers causing their performance to degrade prematurely. Aware of these incompatibilities, DuPont developed a product that would outperform existing elastomers in oxidizing media as well as hot, aggressive amines. The result was Kalrez® Spectrum™ 6380, a cream-colored perfluoroelastomer part.

Based on the Texas facility’s process conditions, Kalrez® Spectrum™ 6380 was the natural choice for the application. Kalrez® Spectrum™ 6380 seal was installed and still in service after one year. The Texas facility had previously tried numerous perfluoroelastomer parts from various manufacturers, but none were able to improve MTBR beyond four months. Due to the 3x improvement in MTBR, the Texas facility continues to specify Kalrez® Spectrum™ 6380 as the preferred elastomer seal in their amine service.

Application Summary

- Temperature: 410 °F (210 °C)

- Incumbent Seal: Various perfluoroelastomers from different manufacturers lasted only 4 months

- MTBR after Kalrez® Spectrum™ 6380: >1 year

As seal lifetime becomes more predictable, production facilities can operate more safely using reliable preventative maintenance schedules that go beyond their current performance levels.

Key Advantages

Every Kalrez® perfluoroelastomer part is formulated to meet the demands of the chemical processing industry using proprietary technology developed by DuPont™, and is involved in the manufacture of Kalrez® perfluoroelastomer parts from the time raw materials are procured until the time finished parts are shipped. This ensures that each Kalrez® part is of the highest quality and satisfies ISO 3601-3 and AS568C requirements.

DuPont™ Kalrez® Spectrum™ 6380 is part of the Kalrez® Spectrum™ family of perfluorelastomer seals known for their high performance in a broad range of chemical processing environments. Kalrez® Spectrum™ 6380 excels in hot, aggressive amines and oxidizing media. 6380 is offered in all standard AS568 and metric sizes and is also available in various custom O-ring sizes and shapes.

Features

Standard Kalrez® O-Ring Compounds

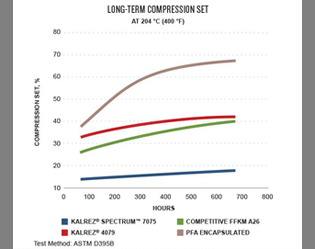

Kalrez® Compounds – 4079

4079 perfluoroelastomer parts are a black, low compression set product for use in many dry and wet semiconductor process environments. It has excellent chemical resistance, good mechanical properties and outstanding thermal stability.

Kalrez® Compounds – 6375

6375 is designed to give outstanding performance in the widest possible range of chemicals and temperatures. This product is an excellent choice for use in acids, bases, amines, steam, ethylene oxide, and many other aggressive chemicals.

Kalrez® Compounds – 7075

7075 is designed for general-purpose use as O-rings or custom sealing components in the chemical and hydrocarbon processing industries. It is a carbon black-filled compound with mechanical properties designed for improved sealing performance in temperature cycling applications. 7075 has improved thermal resistance that extends maximum service temperature to 327 °C (620 F).

Kalrez® Compounds – 0090

0090 perfluoroelastomer parts deliver durable, reliable sealing solutions for applications requiring excellent rapid gas decompression (RGD) properties as well as high hardness and high modulus properties. Some application areas include downhole equipment such as drilling and completion tools as well as industrial equipment including pumps and valves.

Specialty Kalrez® O-Ring Compounds

Kalrez® Spectrum™ – 7375

Kalrez® Compounds -6380

6380 is a non-black product specifically developed for chemical processes involving hot, aggressive amines. It has also been successfully used in applications involving highly oxidizing chemicals. In addition, it has excellent overall chemical resistance. This cream colored product is easily identifiable when selecting an O-ring material for harsh chemical plant services.

Kalrez® Compounds -7090

7090 is a product for uses requiring higher hardness/higher modulus than more typical applications. Kalrez® 7090 perfluoroelastomer parts are well suited for both static and dynamic applications as well as specific sealing applications requiring extrusion resistance at high temperatures.

Kalrez® Compounds -0040

0040 -is a black product specifically designed for low temperature environments where significant chemical resistance is required. Kalrez® 0040 parts maintain elasticity and seal force at temperatures unattainable by other perfluoroelastomers.

Kalrez® Compound – W240

Kalrez® is a registered trademark of E.I. du Pont de Nemours and Company or its affiliates