Home >> Seal >>O-Rings >> Kalrez O-Rings >> Kalrez Case Studies >> O-rings in Pressurized Water Reactor

O-rings in Pressurized Water Reactor

One of the many uses of boiler feed pumps is as part of a Pressurized Water Reactor (PWR) system in nuclear power plants.

In a PWR, the primary coolant (superheated water) is pumped under high pressure to the reactor core. The heated water then transfers thermal energy to a steam generator. Due to the combination of extreme temperature, pressure and chemical environments, an FFKM was used in a series of mechanical seals employed in the operation of boiler feed pumps for PWRs.

The Challenge

Boiler Feed Pump

The temperature and pressure of these pumps are typically 200 °C and 3.5 MPa, with rapid gas decompression in some cases. Media is boiler feed water with dissolved oxygen, ammonia sodium salts and hydrazine. Since the O-rings are mounted in a mechanical seal in pumps connected to the boiler in the secondary unit (i.e., outside of the reactor containment structure), no radiation is present.

The incumbent FFKM O-rings previously used showed signs of thermal and chemical degradation, as well as mechanical degradation. Cracks on the inside of the O-rings indicated that there was high probability that the damage occurred at the time of a rapid gas decompression event, when the pump was switched off. The life time of the seal was less than the required 18 months the customer had specified.

The Solution

The customer tested and specified DuPont™ Kalrez® 0090 parts. Kalrez® 0090 parts offer an excellent combination of chemical, rapid gas decompression (RGD) resistance, and high temperature resistance up to 250 °C for O-ring applications in mechanical seals under these conditions. The use of Kalrez® 0090 parts and components can extend the MTBR (Mean Time Between Repair) of the pumps and reduce leakage which can translate into reduced maintenance costs and increased safety. The customer has replaced all seals that were due for maintenance with Kalrez® 0090.

Features

Standard Kalrez® O-Ring Compounds

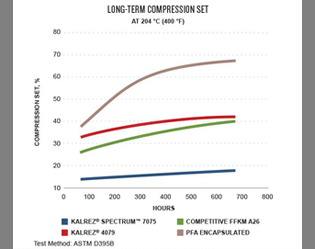

Kalrez® Compounds – 4079

4079 perfluoroelastomer parts are a black, low compression set product for use in many dry and wet semiconductor process environments. It has excellent chemical resistance, good mechanical properties and outstanding thermal stability.

Kalrez® Compounds – 6375

6375 is designed to give outstanding performance in the widest possible range of chemicals and temperatures. This product is an excellent choice for use in acids, bases, amines, steam, ethylene oxide, and many other aggressive chemicals.

Kalrez® Compounds – 7075

7075 is designed for general-purpose use as O-rings or custom sealing components in the chemical and hydrocarbon processing industries. It is a carbon black-filled compound with mechanical properties designed for improved sealing performance in temperature cycling applications. 7075 has improved thermal resistance that extends maximum service temperature to 327 °C (620 F).

Kalrez® Compounds – 0090

0090 perfluoroelastomer parts deliver durable, reliable sealing solutions for applications requiring excellent rapid gas decompression (RGD) properties as well as high hardness and high modulus properties. Some application areas include downhole equipment such as drilling and completion tools as well as industrial equipment including pumps and valves.

Specialty Kalrez® O-Ring Compounds

Kalrez® Spectrum™ – 7375

Kalrez® Compounds -6380

6380 is a non-black product specifically developed for chemical processes involving hot, aggressive amines. It has also been successfully used in applications involving highly oxidizing chemicals. In addition, it has excellent overall chemical resistance. This cream colored product is easily identifiable when selecting an O-ring material for harsh chemical plant services.

Kalrez® Compounds -7090

7090 is a product for uses requiring higher hardness/higher modulus than more typical applications. Kalrez® 7090 perfluoroelastomer parts are well suited for both static and dynamic applications as well as specific sealing applications requiring extrusion resistance at high temperatures.

Kalrez® Compounds -0040

0040 -is a black product specifically designed for low temperature environments where significant chemical resistance is required. Kalrez® 0040 parts maintain elasticity and seal force at temperatures unattainable by other perfluoroelastomers.

Kalrez® Compound – W240

Kalrez® is a registered trademark of E.I. du Pont de Nemours and Company or its affiliates