Home >> Seal >>O-Rings >> Kalrez O-Rings >> Kalrez Case Studies >> Metal O-rings Replacement

Metal O-rings Replacement

Kalrez® O-rings Solve Metal O-ring Deformation

The Challenge

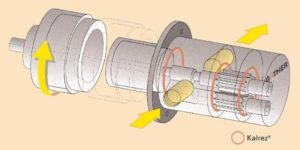

Gather Industrie GmbH, Mettmann, Germany, was facing metal seal deformation problems at high temperatures in gear pumps designed to operate in temperature up to 300 °C and pressure of 100 bar, which was causing leakage at the sealing surfaces and compromising chemical industry safety requirements.

Key markets for pumps, centrifuges and quick-couplings manufactured by Gather are the chemical process and aircraft industries in Austria, Germany and Switzerland. The company’s gear pumps are also used in reactors and other difficult operating environments.

The Solution

By replacing metal O-rings with Kalrez® O-rings from DuPont in gear pumps designed to operate in temperatures up to 300 °C and pressure of 100 bar, Gather Industrie GmbH, Mettmann, Germany, has solved the problem of seal deformation at high temperatures, which was causing leakage at the sealing surfaces and compromising chemical industry safety requirements.

Kalrez® Withstands Extremes

According to Dipl. Eng. Klaus Lübke, the company’s Technical Manager, only Kalrez® O-rings were able to withstand long-term exposure to aggressive chemicals at such extremes of heat and pressure. In numerous other cases, Kalrez® parts fitted up to ten years ago are still working without problem.

Key Advantages

Cost savings with DuPont™ Kalrez®

Unlike metal O-rings, Kalrez® perfluoroelastomer parts also compensate for the uneven internal sealing forces within the asymmetric gear pumps, maintaining a leak-free seal, explains Mr. Lübke. He also reports that by switching to Kalrez®, pump assembly and dismantling has been made easier, leading to cost savings through reduced maintenance and production down time. As a result, Kalrez® seals are now fitted as standard equipment in most of Gather’s extensive range of gear pumps.

Kalrez® perfluoroelastomer parts have provided superior performance in a wide variety of demanding sealing applications. Kalrez® resists more than 1800 chemicals and is thermally stable up to 327 °.

Features

Standard Kalrez® O-Ring Compounds

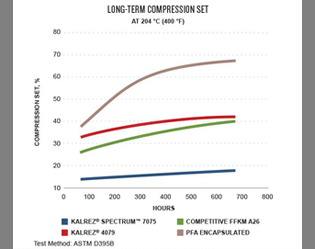

Kalrez® Compounds – 4079

4079 perfluoroelastomer parts are a black, low compression set product for use in many dry and wet semiconductor process environments. It has excellent chemical resistance, good mechanical properties and outstanding thermal stability.

Kalrez® Compounds – 6375

6375 is designed to give outstanding performance in the widest possible range of chemicals and temperatures. This product is an excellent choice for use in acids, bases, amines, steam, ethylene oxide, and many other aggressive chemicals.

Kalrez® Compounds – 7075

7075 is designed for general-purpose use as O-rings or custom sealing components in the chemical and hydrocarbon processing industries. It is a carbon black-filled compound with mechanical properties designed for improved sealing performance in temperature cycling applications. 7075 has improved thermal resistance that extends maximum service temperature to 327 °C (620 F).

Kalrez® Compounds – 0090

0090 perfluoroelastomer parts deliver durable, reliable sealing solutions for applications requiring excellent rapid gas decompression (RGD) properties as well as high hardness and high modulus properties. Some application areas include downhole equipment such as drilling and completion tools as well as industrial equipment including pumps and valves.

Specialty Kalrez® O-Ring Compounds

Kalrez® Spectrum™ – 7375

Kalrez® Compounds -6380

6380 is a non-black product specifically developed for chemical processes involving hot, aggressive amines. It has also been successfully used in applications involving highly oxidizing chemicals. In addition, it has excellent overall chemical resistance. This cream colored product is easily identifiable when selecting an O-ring material for harsh chemical plant services.

Kalrez® Compounds -7090

7090 is a product for uses requiring higher hardness/higher modulus than more typical applications. Kalrez® 7090 perfluoroelastomer parts are well suited for both static and dynamic applications as well as specific sealing applications requiring extrusion resistance at high temperatures.

Kalrez® Compounds -0040

0040 -is a black product specifically designed for low temperature environments where significant chemical resistance is required. Kalrez® 0040 parts maintain elasticity and seal force at temperatures unattainable by other perfluoroelastomers.

Kalrez® Compound – W240

Kalrez® is a registered trademark of E.I. du Pont de Nemours and Company or its affiliates