Home >> Seal >>O-Rings >> Kalrez O-Rings >> Kalrez Case Studies >> Kalrez® Spectrum™ 6375 O-rings for PTFE replacement

Kalrez® Spectrum™ 6375 O-rings for PTFE replacement

The Challenge

The filling line at Dow AgroSciences plant in Drusenheim, France – a global leader in pest management and biotechnology products – processes aggressive solvents, surfactants and concentrated herbicides at temperatures ranging from 10 to 45 °C, and pressures from 1.5 to 3.5 bars Eff. Filling machine valves on the line were fitted with dynamic PTFE O-rings, while the machine hoses were equipped with static O-rings, also of PTFE.

Each time the mechanical maintenance team performed a clean-in-place procedure at 80 °C, or made a product change on the filler, the PTFE seals became mechanically damaged. This meant they had to change the PTFE O-rings on a daily basis, since seal lifetime never extended beyond 24 hours before replacement.

In a different application at the same plant, seals of FEP/FKM, fitted to the piston rod of a Type SRC Alfa Laval valve, failed regularly after only 8 hours operation.

The cost to Dow AgroSciences in extra performance time and maintenance had become unacceptable, and the company sought a much more resilient sealing material that would better withstand frequent cleaning and product changes.

The Solution

Dow Agro Sciences S.A. installed Kalrez® Spectrum™ 6375 perfluoroelastomer O-rings to replace the PTFE seals, with dramatic and immediate improvement.

They managed to extend the lifetime of dynamic and static seals fitted to their product filling line from one day to an average of two months, an improvement of some 6000%.

Also the seals of FEP/FKM, fitted to the piston rod of a Type SRC Alfa Laval valve, were replaced by Kalrez® perfluoroelastomer parts. Operating lifetime has increased from 8 hours to between 8–12 months!

Kalrez® Spectrum™ 6375 parts are designed specifically for the chemical process industry. They provide outstanding performance in an extremely wide range of chemicals including acids, bases, amines and steam. The innovative patented curing system allows for continuous upper service temperatures of up to 275 °C in applications such as mechanical seals, valves, flanges and pumps where elastomeric sealing is critical.

In addition, Kalrez® is a thermoset perfluoroelastomer part and offers excellent elastic properties and resistance to mechanical damage, unlike PTFE which is a thermoplastic and appears to lack the necessary resilience to withstand mechanical shock in a process application such as this.

Key Advantages

Since switching to custom Kalrez® Spectrum™ 6375 O-rings Dow AgroSciences S.A. reports an average seal lifetime of two months. That’s an increase of approximately 6,000% over the previously fitted PTFE seals.

The operating lifetime of the seals fitted to the piston rod of a Type SRC Alfa Laval valve increased from 8 hours to between 8–12 months.

Switching to Kalrez® Spectrum™ 6375 parts allowed Dow AgroSciences to increase the operating uptime of their filling machines and to improve overall reliability of their packing line. They have also significantly reduced the time spent in O-ring replacement. The Mechanical Maintenance Manager also reported cost savings as a result of major improvements in safety and reliability, and in reduced maintenance.

Features

Standard Kalrez® O-Ring Compounds

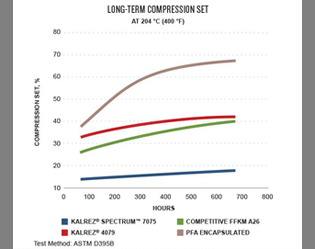

Kalrez® Compounds – 4079

4079 perfluoroelastomer parts are a black, low compression set product for use in many dry and wet semiconductor process environments. It has excellent chemical resistance, good mechanical properties and outstanding thermal stability.

Kalrez® Compounds – 6375

6375 is designed to give outstanding performance in the widest possible range of chemicals and temperatures. This product is an excellent choice for use in acids, bases, amines, steam, ethylene oxide, and many other aggressive chemicals.

Kalrez® Compounds – 7075

7075 is designed for general-purpose use as O-rings or custom sealing components in the chemical and hydrocarbon processing industries. It is a carbon black-filled compound with mechanical properties designed for improved sealing performance in temperature cycling applications. 7075 has improved thermal resistance that extends maximum service temperature to 327 °C (620 F).

Kalrez® Compounds – 0090

0090 perfluoroelastomer parts deliver durable, reliable sealing solutions for applications requiring excellent rapid gas decompression (RGD) properties as well as high hardness and high modulus properties. Some application areas include downhole equipment such as drilling and completion tools as well as industrial equipment including pumps and valves.

Specialty Kalrez® O-Ring Compounds

Kalrez® Spectrum™ – 7375

Kalrez® Compounds -6380

6380 is a non-black product specifically developed for chemical processes involving hot, aggressive amines. It has also been successfully used in applications involving highly oxidizing chemicals. In addition, it has excellent overall chemical resistance. This cream colored product is easily identifiable when selecting an O-ring material for harsh chemical plant services.

Kalrez® Compounds -7090

7090 is a product for uses requiring higher hardness/higher modulus than more typical applications. Kalrez® 7090 perfluoroelastomer parts are well suited for both static and dynamic applications as well as specific sealing applications requiring extrusion resistance at high temperatures.

Kalrez® Compounds -0040

0040 -is a black product specifically designed for low temperature environments where significant chemical resistance is required. Kalrez® 0040 parts maintain elasticity and seal force at temperatures unattainable by other perfluoroelastomers.

Kalrez® Compound – W240

Kalrez® is a registered trademark of E.I. du Pont de Nemours and Company or its affiliates