Home >> Seal >>O-Rings >> Elastomers Temperature and Durometer

Elastomers Temperature and Durometer

The chart matches the general rubber properties required in most O-ring applications with the capabilities of commonly used elastomers. Since no one elastomer is rated “excellent” for all properties, compromises are sometimes necessary when selecting an elastomer for a specific O-ring application. Start with the most critical properties to narrow your choices.

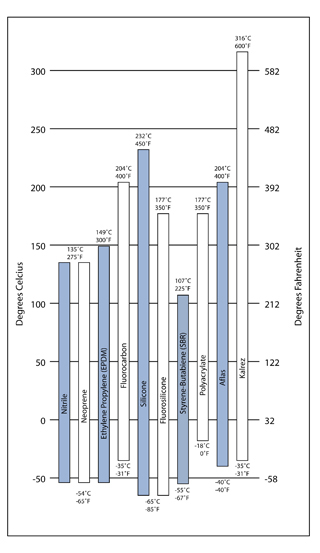

Temperature Range

The temperature range for any compound is determined by the base elastomer used. This chart depicts the maximum temperature range for each elastomer. The temperature range for a specific compound may not reach these maximum limits. Higher temperatures may be considered if exposure is short term or intermittent.

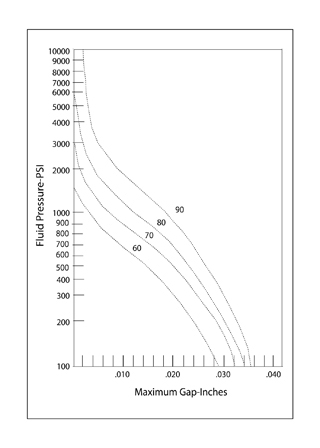

Durometer Chart

The hardness of rubber compounds is commonly measured by the Shore ‘A’ durometer; the higher the durometer number, the harder the compound. 70-durometer hardness should be used wherever possible as it offers the best combination of properties for most O-Ring applications. Softer compounds stretch easier and seal better on rough surfaces. Harder compounds offer greater abrasion resistance and resistance to extrusion. Extrusion must always be considered where high pressures are used. The proper hardness may be selected from this chart by matching the fluid pressure with the maximum extrusion gap.