Home >> Shaft Seals >> WAD Seals

WAD Seals

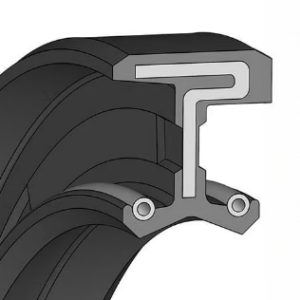

The WAD Seals are highly adaptable sealing component designed with a dual-effect for efficient sealing performance. It features two sealing lips, each supported by spiral springs, providing a secure seal. The outer diameter is covered with an elastomer for a smooth surface, with the option for a ribbed outer diameter available upon request.

The WAD Seal design makes it ideal for various applications, excelling in the separation of two media with its double-lip configuration. This ensures effective sealing and prevents the mixing of different fluids or substances. It provides a reliable static seal within the housing, preventing leaks or contamination, and is particularly suited for housings with high thermal expansion, such as those made of light metals. Additionally, it performs well in shared housings and applications with rougher surfaces. WAD Seals, also, offer protection against fretting corrosion for long-term reliability.

One common application of the WAD Seal is in rotating machine parts, where it ensures the separation of fluids or substances, optimizing performance and preventing cross-contamination.

The standard materials utilized for the WAD Seal include NBR 70 black elastomer for the sealing element, with the springs made of spring steel (DIN EN 10270-1) and the reinforcement ring made of sheet steel (DIN EN 10139). For specialized needs, materials like FKM, silicone, ACM, HNBR, CR, and EPDM elastomers are available. The spring and reinforcement ring can also be made from rust- and acid-resistant steel (1.4301) for enhanced durability.

Operating parameters include a temperature range of -40°C to +100°C, a maximum pressure of 0.02 MPa, and a circumferential speed limit of 6 m/s. For lubrication, mineral and synthetic oils are recommended. Compatibility testing should be done when using synthetic lubricants without empirical data, and the operating temperature should not exceed 80°C for best performance.

Regarding construction, the shaft tolerance follows ISO h11 standards, with a minimum hardness of 45 HRC. The recommended shaft roughness is Ra 0.2-0.8 μm, with an Rz of 1-5 μm and an Rmax of no more than 6.3 μm.

Technical Resources