Home >> Blog >> The Benefit of Hammer Union Seals

The Benefit of Hammer Union Seals

Hammer Union Seals are utilized in hammer union-style pipe connections to create flow lines and prevent leakage. Hammer unions are especially designed to enjoin mud tanks immediately without managing the flanged connections. In case if the issue is so that the mud tanks are not aligned properly, hammer unions can still be utilized in order to create absolutely non-leak seals that are tightened. They are designed as heavy duty, high pressure flow line connectors and are used in the oil & gas industry, in steel mills, chemical plants, strip mining, and marine dredging.

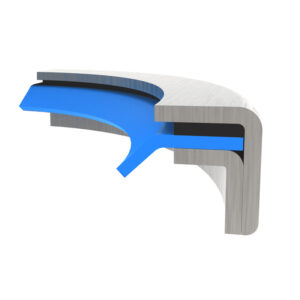

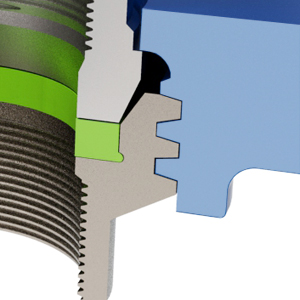

A hammer unions are comprised of a thread end, a nut end and a hammer nut which, when cinched up, compresses a composite seal assembly thereby preventing leakage. The seal assembly comprises a metal insert of a size to pass into the seal groove of conventional hammer unions and a small seal acting between the insert, the thread end and the nut end. The small seal is conveniently an O-ring or a Hammer Union Seal (Lip Seal) and is of a size that is compressed when the seal assembly is inserted into the thread end of the hammer union.

Proven Seal Designs

-

-

High-Pressure Services (6,000 to 20,000 psi)

Hammer Unions for high-pressure services feature a replaceable, lip-type seal ring in the female sub. This primary seal protects the secondary metal-to-metal seal from abrasion and corrosion while minimizing flow turbulence.

-

-

-

Non-Pressure Seal Thread Hammer Union

This type is especially designed for abrasive, high-pressure (15,000 psi) Hammer Union services where welded connections are undesirable. This design provides strong, permanent end connections without butt welding. The union ends are shop assembled to pipe or tubing. An epoxy thread compound is used to secure the connection. Since all threads are isolated from the fluid line, the resulting smooth bore assures minimum turbulence, decreased washout and reduced buildup around pipe ends of acid, sand, cement or chemicals. Connecting threads are API 10 round.

-

Cold Weather Applications of Hammer Union Seals

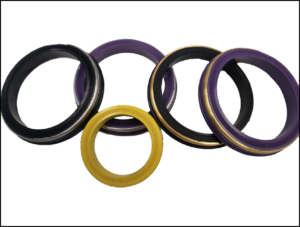

Our Hammer Union Seals are available in a range of configurations and materials to match the specific performance requirements of your demanding operating enivronments.

- For cold weather applications we offer both a low temperature rated (-50°C to +120°C) NBR and HNBR elastomers.

- Our NBR is availabe with a Brass reinforcing ring and both our HNBR and Viton Hammer Unions Seals are available with a Stainless Steel reinforcing ring.

- A range of elastomer hardnesses from 70 to 90 durometer.

- Other Hammer Union Seal elastomers include PTFE and a Yellow Viton.

Recommended service: Cementing, fracturing, acidizing, testing, and choke-and-kill lines

Positive sealing: Primary elastomer seal and metal-to-metal seal combine to deliver positive sealing throughout the stated pressure range.

Hammer unions use a special rubber seal ring for positive sealing with minimum torque. This ring snap-fits into a detent within the hub to prevent its loss. Hammer unions are available in 1 in. to 4 in. line pipe sizes.

Seal Size: 1”, 1-1/4”, 1-1/2”, 2”, 2-1/2”, 3”, 4”

Seal Material: NBR, HSN, Viton and PTFE

To learn about selecting the correct products for your operating environment please contact your local Daemar Technical Sales Representative or checkout our Hammer Union Seals.