Home >> Seal >>O-Rings >> O-Ring Groove Design

Technical Resources

- O-Ring Catalogue

- Comparison of Properties

- Temperature & Durometer

- Elastomers

- Fluid Compatibility Selector

- Shelf Life and Storage

- Causes of O-Ring Failure

- O-Ring Design & Lubrication

- Glossary of O-Ring Terms

| RING SIZE | CROSS-SECTION | Dynamic Recommended Gland Depth “C”

|

Static Recommended Gland Depth “C” | Axial Groove Width “D” | Groove Eccentricity (TIR) | |||||

|---|---|---|---|---|---|---|---|---|---|---|

| (inches) | (mm) | (inches) | (mm) | (inches) | (mm) | (inches) +.005 / -.000 | (mm)

+.005 / -.000 |

(inches) | (mm) | |

| Q4004 – Q4050 | .070 +/- .003 | 1.78 +/- 0.08 | .061 | 1.55 | .056 | 1.42 | .080 | 2.03 | .002 | 0.05 |

| Q4102 – Q4178 | .103 +/- .003 | 2.62 +/- 0.08 | .094 | 2.39 | .089 | 2.26 | .115 | 2.92 | .002 | 0.05 |

| Q4201 – Q4284 | .139 +/- .004 | 3.53 +/- 0.10 | .128 | 3.25 | .122 | 3.10 | .155 | 3.94 | .003 | 0.08 |

| Q4309 – Q4395 | .210 +/- .005 | 5.33 +/- 0.13 | .196 | 4.98 | .188 | 4.78 | .240 | 6.10 | .004 | 0.10 |

| Q4425 – Q4475 | .275 +/- .006 | 6.99 +/- 0.15 | .256 | 6.50 | .244 | 6.20 | .310 | 7.87 | .005 | 0.13 |

1. Cross-section

Select a Quad-Ring cross section size from the available standard size.

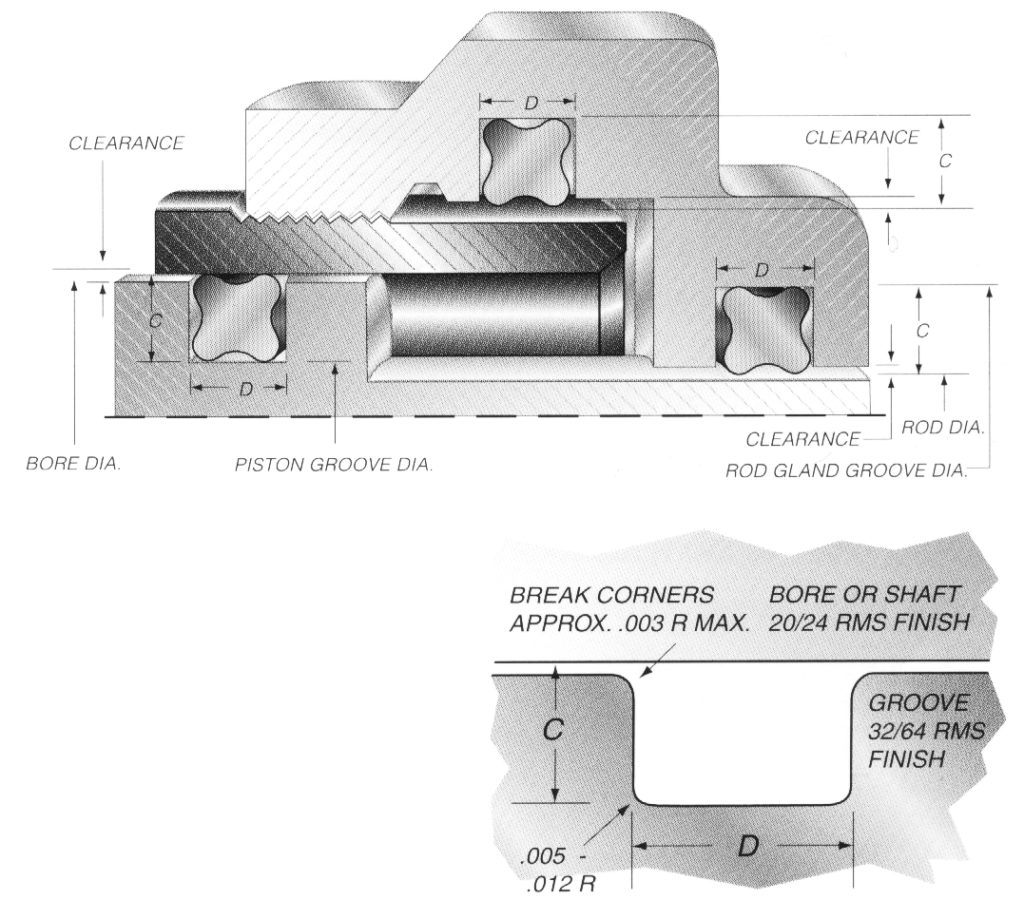

2. Clearance

Determine the maximum clearance present in your application. For a radial seal, subtract the minimum rod (shaft) diameter. For a face seal, subtract the distance between the sealing surface and the mating surface.

3. Check the Clearance

Determine if the clearance is acceptable for the application pressures and the material hardness being used. Standard-line products are made from materials having a hardness of 70 Shore A. If the clearance is unacceptable, component tolerance will have to be tightened, a harder material will have to be special ordered, or a back-up ring will have to be used.

4. Calculate Quad-Ring Groove Dimensions

Using the table above, determine the maximum recommended gland depth for your application. Then, calculate the Quad-Ring groove diameter as follows:

a. For a rod (shaft seal:

Quad-Ring Groove Diameter = Min Shaft Diameter + (2 X Recommended Gland Depth)

b. For a bore (piston) seal:

Quad-Ring Groove Diameter = Max Bore Diameter – (2 X Recommended Gland Depth)

c. For face seal:

Quad-Ring Groove Depth = Recommended Gland Depth – Application Clearance

With a face seal, if the two surfaces to be sealed are in direct contact (such as with a cover), the seal groove depth is simply the Recommended Gland Depth.

5. Groove Width

Refer to the table above to determine the groove width for the Quad-Ring cross-section size you have selected. If you are using a back-up ring in your application, increase the groove width by the maximum thickness of the back-up ring.

6. Percent Gland Fill

If the gland fill exceeds 100%, the groove wil have to be redesigned. A good “rule of-thumb” is to not exceed about 90% gland fill.

7. Calculate the Seal Squeeze

The recommended gland values in the table above have been developed to create a proper range of squeeze for many applications involving oil, hydraulic fluid, or normal lubricants, providing component tolerances are sufficiently controlled.

In applications involving high pressure, large component tolerances, the need for very low frictional forces, or other types of fluids, the seal and groove design should be verified through

an acceptable method, such as testing or engineering analysis.

8. Select the Seal

If the bore or shaft size you are using is not listed, select the Quad-Ring with and inside diameter just smaller than the shaft you are using. If you are designing a face seal, select the Quad-Ring with and inside diameter which will position the Quad-Ring on the side of the groove opposite the pressure. Note: If the seal stretch is greater than 3% you may have to use the next size up.

9. Detail the Groove

Complete the groove design by specifying the proper radii and finish as indicated in the figure above.