Home >> Seal >> O-Rings >> Metal Detectable O-Rings >> Material Detection in the field

Material Detection in the Field

As a result of excessive use, shearing and damage can occur to equipment causing undetectable product contamination. Metal detectables can eliminate product recall, lower product loss and decrease the risk of elastomers consumed in finished product.

A common problem with component and filler parts is excessive wear and tear. When rubber breaks off a moving part it can migrate through your system and into your product. Searching for and locating fragmented rubber parts is a costly, time consuming and inconclusive process requiring expensive x-ray equipment, manual observation and an extensive maintenance program. Not locating a worn and lost rubber piece can have an even costlier outcome. By manufacturing a standard elastomer with a metal impregnated compound, displaced rubber material can now be located by an in-line metal detector. This alarm enables your system to instantly reject contaminated product.

Material Detection in the field.

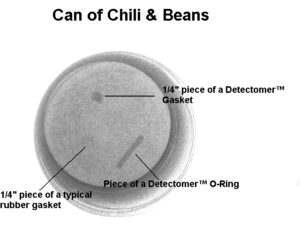

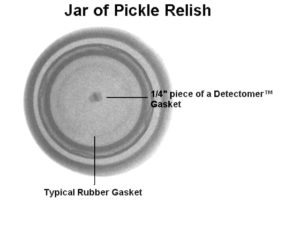

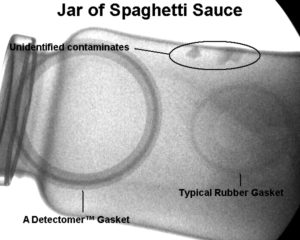

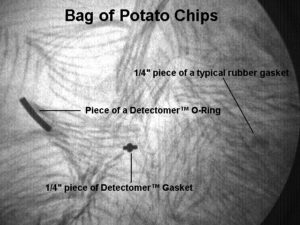

Example(s) of 1/4″ of Detectomer gasket in the field can be viewed on the images below.

View Detectable Material Scans pdf for more images.

Detectable O-Ring Materials:

- Buna

- EPDM

- FKM

- Silicone

- Tuf-Steel™

Meets Industry Standards:

- Elastomers meet Title 21 CFR 177.2600

- Tuf-Steel meets Title 21 CFR 177.1550

- Meets USDA Hazard Analysis and Critical Control points.

- Detectable metal additive meets the latest revision of the Food Chemicals Codex*

- Animal Derived Ingredient Free†* The Food Chemicals Codex Project is an activity of the food and nutrition board of the Institute of Medicine and is supported by the U.S. Food and Drug Administration.™ Tuf-Steel and ADI Free are trademarks of Rubber Fab Technologies Group.† Buna is not an ADI Free elastomer