Home >> Shaft Seals >> JM Clipper Seals >> JM Clipper Shaft Design

JM Clipper Shaft Design

Proper application design of the shaft assures proper sealing performance. Using the following guide will ensure the best possible sealing environment for your JM Clipper seals.

Shaft Recommendations

Material —

JM Clipper recommends a shaft material of carbon steel with a minimum hardness of Rockwell C30 (30 Rc). Soft materials such as bronze, aluminum or plastic should be avoided because they are susceptible to grooving and will cause premature seal failure. If a soft shaft material must be used, a Daemar Shaft Repair Sleeve can be installed over the soft shaft material to provide a durable sealing surface.

Shaft Finish—

JM Clipper recommends a plunge ground finish of 8 to 17 μin Ra (0.20 to 0.43 μm Ra) with zero lead. A shaft finish significantly smoother or rougher will shorten the service life of the seal.

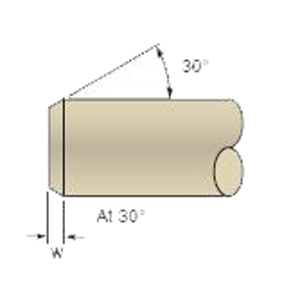

Shaft Profile —

The shaft profile should include a lead-in chamfer per the following example. The leading edge helps prevent lip roll-back and spring dumping. The leading edge and trailing edges should be free of burrs or sharp edges that could cut the contact point of the seal lip. See Table on right for recommended minimum chamfer length.

Chamfer Length

| Shaft Diam. up to and including | Length “w” (inch) | Metric Shaft Diam. upto and Including | Length “w” (mm) |

|---|---|---|---|

| 0.375 | 0.051 | 10 | 1.3 |

| 0.750 | 0.068 | 20 | 2.0 |

| 1.250 | 0.085 | 30 | 2.2 |

| 1.5 | 0.102 | 40 | 2.6 |

| 2.000 | 0.119 | 50 | 3.0 |

| 2.750 | 0.136 | 70 | 3.5 |

| 3.750 | 0.153 | 95 | 3.9 |

| 5.000 | 0.188 | 130 | 4.8 |

| 9.00 | 0.239 | 240 | 6.1 |

| +18.000 | 0.375 | 480 | 10.0 |

Shaft Tolerance —

To ensure the proper lip-to-shaft interference is maintained, shaft diameters should fall within the tolerances specified in Tables 5-1 and 5-2. Shafts significantly over the tolerance will increase the underlip temperatures and lead to premature failure. An undersized shaft compromises the amount of lip interference available to maintain a positive seal.

Table 5-1. Shaft Tolerance for Inch/Fractional

| Shaft Diameter | Tolerance |

|---|---|

| Up to 4.000″ | ±.003″ |

| 4.001 – 6.000″ | ±.004″ |

| 6.001 – 10.000″ | ±.005″ |

| Over 10.000″ “ | ±.006 |

Table 5-2. Shaft Tolerance for Metric*

| Shaft Diameter | Tolerance |

|---|---|

| Up to 10 mm | +0 to -.09 mm |

| Over 10 – 18 | +0 to -.11 mm |

| Over 18 – 30 | +0 to -.13 mm |

| Over 30 – 50 | +0 to -.16 mm |

| Over 50 – 80 | +0 to -.19 mm |

| Over 80 – 120 | +0 to -.22 mm |

| Over 120 – 180 | +0 to -.25 mm |

| Over 180 – 250 | +0 to -.29 mm |

| Over 250 – 315 | +0 to -.32 mm |

| Over 315 – 400 | +0 to -.36 mm |

| Over 400 – 500 | +0 to -.40 mm |