Home >> Blog >> Establish a New Supply Chain Resilience in Semiconductors Applications with Turcon® Variseal®

Establish a New Supply Chain Resilience in Semiconductors Applications with Turcon® Variseal®

Seals are commonly used in the semiconductor industry to protect sensitive electronic components and devices from contamination, moisture, and other environmental factors. As the semiconductor industry is experiencing a period of robust growth, driven by the increasing demand for consumer electronics, AI, 5G technology, and the automotive and aerospace industries, higher quality and more efficient seals are required to meet the demanding needs of these breakthrough applications. The quality of the seal being used cannot be compromised as it poses a high risk of operational failure, or worse, sparks or explosions.

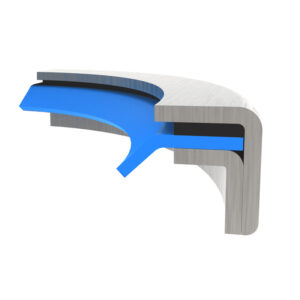

Trelleborg’s New Turcon® Variseals® offers high specific sealing force and is created while keeping the semiconductor industry challenges in mind. They are spring-energized seals for high vacuum and corrosive environments and have been tested to show high performance in extreme gas and liquid handling situations.

Trelleborg’s Turcon® Variseals are offered in different variations to meet the requirements of different kinds of applications. These include:

- Turcon® Variseal® NW: The design of this flange seal, featuring a Turcon® case, completely encloses the energizing spring, preventing any contact between it and the system media. It makes it an ideal choice for semiconductor applications, as it can function effectively in vacuum environments and has been tested and proven in fluorine gas.

- Turcon® Variseal® PS™: This is a high-performing seal which uses a Turcon® PTFE-based sealing body and a polymeric spring. It is engineered to activate at low pressures while maintaining high-pressure sealing capabilities by utilizing the system’s media pressure. Additionally, it has extremely low levels of impurities and minimal outgassing, making it suitable for use in semiconductor wet processing, meeting the SEMI standard F57-0301.

- Turcon® Variseal® Ultra-Clean™: This seal is highly effective in maintaining a clean environment, making it suitable for use in equipment that requires ultra-cleanliness. Its unique design features an enclosed spring that is completely encased in a Turcon® case, preventing any metal extractable from contaminating the system. It is particularly essential in semiconductor manufacturing, where even small amounts of contamination can destroy the effectiveness of wafers.

It is vital to choose an experienced seal manufacturer to ensure authentic quality and performance in accordance with ISO, ASTM, and DIN standards. Trelleborg is known for its quality components and for meeting regulatory compliance. Daemar, authorized Trelleborg distributor, can help you with your requirement for Turcon® Variseal® for extreme semiconductor applications so you can operate your assembly line worry-free and with high efficiency. Thus, establishing a New Supply Chain Resilience in Semiconductors Applications. To learn more about Turcon® Variseal®, please contact your local Daemar Technical Sales Representative.