Home >> Slide >> Fiber-Lube Bushings >> CJ/FCJ Fiber-Lube Installation

CJ/FCJ Fiber-Lube Installation

Proper installation of components is critical to achieving the best results. Daemar recommends the following methods to ensure optimum bearing material performance.

Installation

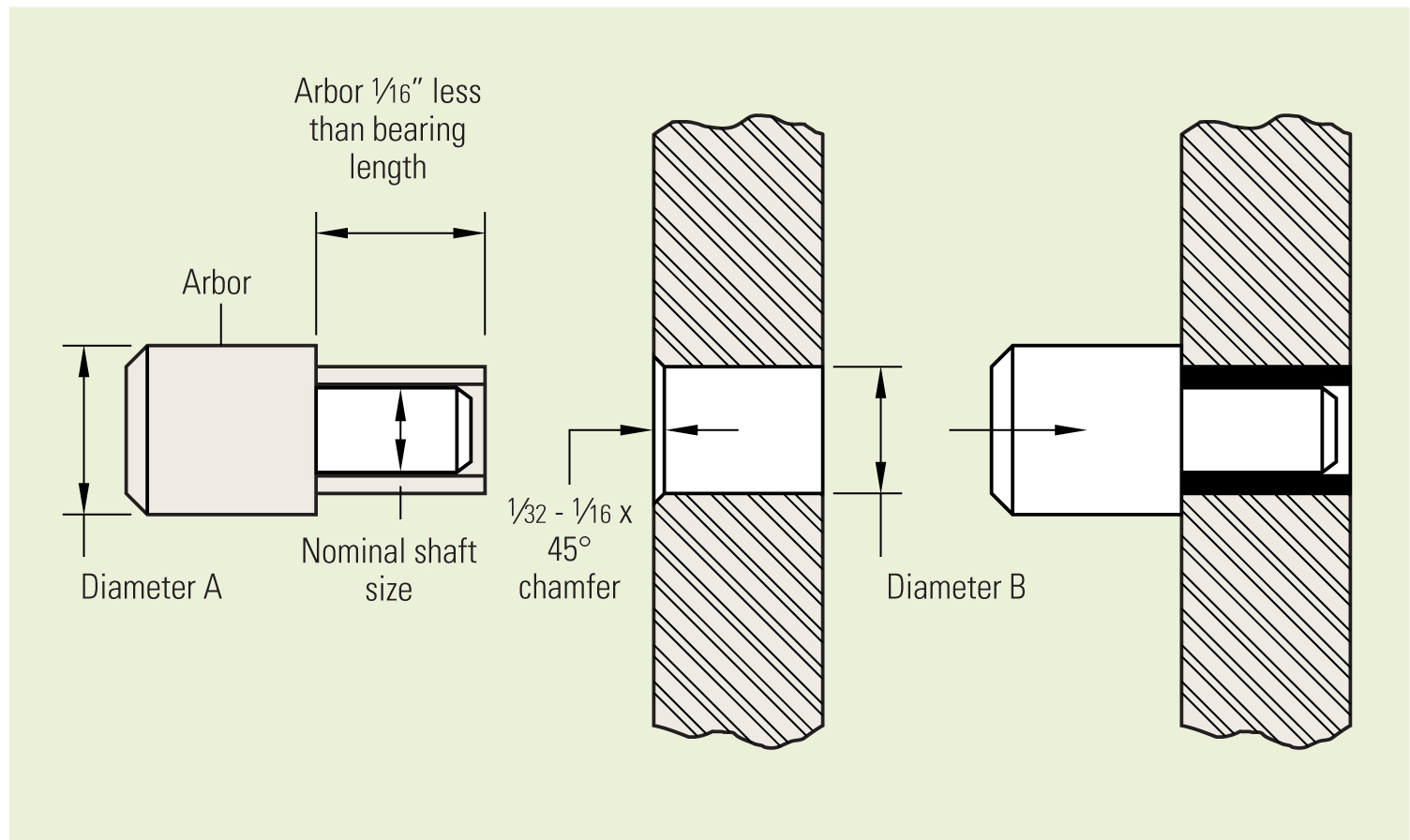

Composite bearings install easily. Use a shouldered arbor plug for standard press-fit installation. The diagram below shows arbor, housing, bearing, and shaft relationships.

Press Fit Installation Using Standard Housings

The dimensions recommended here ensure proper interference fits. Using these standard bearing, shaft, and housing dimensions usually eliminates the need for further machining or reaming of the bearing.

Press Fit Installation Using Non-Standard Housings

When using non-standard housings, you can machine a small amount of material from the O.D. of CJ bearings.

Be sure the bearing is mounted on a pin of the proper diameter to prevent out-of-roundness. Daemar recommends carbide or diamond tipped tool bits.

When replacing only the bearing, be sure to clean the existing housing. Thoroughly machine it to size if necessary. Take care to remove sharp edges and add proper chamfers.

Other Installation Methods

You can use other means of retention like staking, retainer rings, or bonding.

Fabrication & Machining Fabric Lined Bearings

O.D. Machining: CJ bearings can be ground or turned to finished size. Daemar recommends carbide or diamond tipped tools for cutting.

Drilling: Cross drilling is acceptable for lubrication and installation, but take care not to damage the synthetic fiber/PTFE liner. Contact Daemar for assistance in drilling radial through holes.

Cutoff: Daemar recommends using a diamond wheel for abrasive cutoff. Chamfer I.D. and O.D. edges with a high-speed grinder.

I.D. Machining: Machining the l.D. of CJ bearings is not recommended. Broaching, reaming, grooving, honing or boring destroy the synthetic fiber/PTFE liner. If the bore must be modified, contact Daemar for guidance.

Bonding: Bond to housing using standard epoxies. No special surface treatment is required. Clean and degrease prior to bonding.

Read about Bearing Wear (CJ/FCJ Series) and Lubrication Requirements.