Home >> Retaining Rings >> Retaining Rings Design Considerations

Retaining Rings Design Considerations

Technical Resources

Reduce your fastener assembly costs by designing in a Retaining Ring. Consider replacing costly traditional fasteners with retaining rings and enjoy savings you didn’t know were possible. Retaining Rings can also handle many “Non-Traditional” fastener requirements for even greater savings. Before you designate a retaining ring for your application, follow these simple design considerations steps.

STEP 1 – DETERMINE THE RING TYPE

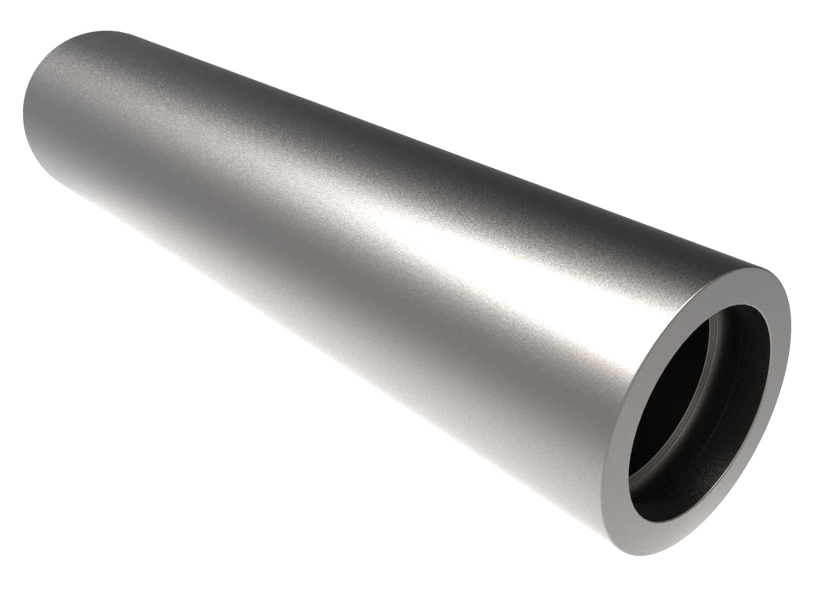

Axial Retaining Ring: If the assembly you must retain is in a housing/bore, then you need an internal type or HOUSING (HO) ring or axial retaining ring.

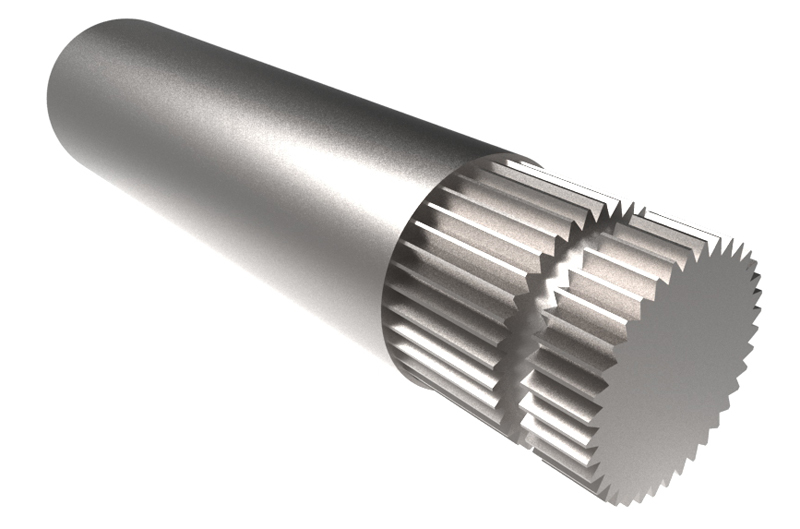

Radial Retaining Ring: If the assembly you must retain is on a shaft, then you need an external type or SHAFT (SH) ring or radial retaining ring.

If you are looking for a retaining ring to act as a spring or as a preload on parts to reduce chatter or vibration, then you need either a bowed (BHO, BSH for resilient end-play take up) or a beveled (VHO, VSH for rigid end-play take up) retaining ring. These are available for both internal and external applications.

There are two other important variations of both HO internal rings and SH external rings. The “Bowed” HO (BHO)…

…and “Bowed” SH (BSH), so named because they are shaped like a bow, and are used to compensate for accumulated tolerances.

If the assembly you must retain is characterized by very little thrust load, consider a self-locking retaining ring. These require no groove and are ideal for use on shaft/housing diameters of 1″ or less.

RG style “Radial Grip Ring

STEP 2 – INSTALLATION CONSIDERATIONS – AXIAL VERSUS RADIAL

How the ring is to be installed will affect the type of ring you select. If the installation is axial, (along the axis or center point of a shaft/housing), you will need an Axial Retaining Ring. These include HO, SH, HOI, SHI, SHR, SHM rings, which can viewed on our website.

Axial, along the center point of a shaft or housing.

If installation is radial, (along the radius of a circle), you will need a Radial Retaining Ring. These include E, RE, C, PO/POL, LC rings listed in the radial section of the catalog.

STEP 3 – RING SIZE

Measure the diameter of the housing or shaft. This dimension will give you the size retaining ring you will need. Retaining rings are made to Inch, DIN, and ANSI Metric standards. “E” retaining rings are also available to JIS (Japanese) standards.

STEP 4 – MATERIAL

Select the right retaining ring material for your application.

STEP 5 – FINISHES

Select the right retaining ring finish for your application.

Check out materials, finishes or packaging sections.

STEP 6 – INSTALLATION TOOLS

- This important step is all too often overlooked. Selecting the right tool for your assembly needs should be a high priority. Don’t wait until your rings are delivered before looking into installation issues.

- Rotor Clip retaining rings can be installed using any of a variety of manual and automatic tools, including pliers and pneumatic tools for axial retaining rings, and applicators and dispensers for radial retaining rings. Many of these feature ergonomic designs that reduce the risk of Carpal Tunnel Syndrome. Avoid using fingers, hammers and makeshift devices as these can cause injury as well as damage to the application.

Example

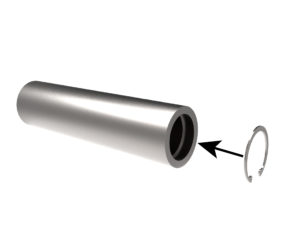

Based on steps 1-6, you conclude that your application calls for retaining an assembly in a housing, where end-play is not a problem. The housing diameter is .500″. Installation will be in an axial direction. Material will be carbon spring steel, with a Zinc Dichromate Finish, since corrosion protection will be a factor in preserving your assembly from rust.

The catalog calls out an axially installed HO-0050. Since installation will be manual, you select an RP-100 retaining ring plier as the primary installation tool. Bulk packaging will be sufficient.

You now have all the specifications related to that ring listed in the catalog. Be sure to review them carefully.

Other Considerations

Standard Versus Custom

Selecting a standard retaining ring will always be more cost effective than designing a custom retaining ring. It will also save on engineering time, eliminate production problems and ensure timely delivery of product. Daemar technical sales engineer can help you find a suitable standard replacement for a custom retaining ring.

Standard Versus Inverted

If you have another assembly that must pass through the housing of your application. Check the Clearance Diameters “L1” and “L2” dimensions. This will tell you if the lugs of the ring will interfere with this assembly. If this is the case, you can switch the ring to an HOI (Housing Inverted) (or SHI Shaft Inverted for a shaft application). This ring features inverted lugs for better clearance.

Axial Versus Radial

If your application can accept either an axial or a radial retaining ring, shoulder size, thrust load and RPM may determine which type you use. Be sure to check these specifications carefully before making your selection. (Keep in mind that radial rings offer enlarged shoulders for part retention and generally cost less than standard axial rings).

E Verus RE Rings

If you selected an E ring and later discovered that it cannot withstand the RPM generated by your application, you can change it to a standard RE ring. RE rings fit into the same grooves as E rings and can be easily interchanged without re-designing the application.

Different E Ring Designations

The “E” ring specification pages in the Daemar catalog list many variations. For example, E-18, SE-18, YE-18 and ZE-18 are not “specials” but simply different parts that can be used on the same shaft size. They will function in applications having either different groove diameters/groove depths for the same size shaft (3/16″). They also offer optional geometry for a specific shaft size. Often, the O.D., ring thickness and groove dimensions vary for SE, YE and ZE part numbers.

PO Versus POL

This ring series offers a similar advantage as the E and RE. The PO is complemented by a “light duty” series known as POL that is thinner than the standard PO rings.

SH Versus SHR

An SHR is a heavy duty version of an SH ring with increased thickness and minimum/maximum sections that will give you increased thrust load and RPM limits. Keep in mind that an SHR requires a wider groove than an SH before you make the switch.

Duplicate Ring Designations

Some retaining rings are listed twice in the catalog (Ex. HO-156). This means that the same ring will function in two separate applications that have different housing/shaft and groove sizes.

Installation Considerations

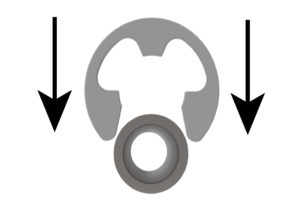

An external axial ring (SH, SHI, etc.) can be over expanded during installation. To prevent this, take a pin gauge 1% larger than the nominal shaft diameter of your application. Using a Rotor Clip retaining ring plier and safety goggles, expand the ring and release it on the gauge. With the tips still in the lugs, adjust the stop to this opened condition.

To learn about selecting the correct products for your operating environment please contact your local Daemar Technical Sales Representative.