Home >> Blog >> The Best Springs you Haven’t Tried Yet

The Best Springs You Haven’t Tried Yet

Flat wire wave springs offer the best balance of size and spring force. Here’s what you need to know to design with these high-performance alternatives to traditional springs.

Even if you routinely use spring elements in your designs, chances are you haven’t tried wave springs yet. You’re not alone. Most engineers have plenty of experience with traditional coil and disc springs, while single- and multi-turn wave springs remain something of a mystery. Yet wave springs particularly those made from flat wire, should be better known given their compelling engineer advantages.

Chief among these advantages is an excellent force-to- work height ratio. Well-designed wave springs can produce the same or even greater forces as coil springs whose work heights are up to twice as large.

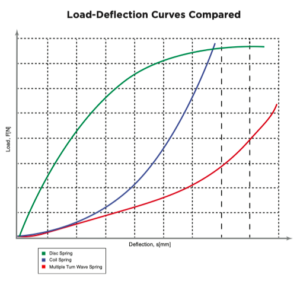

Good wave springs also produce a more consistent force across a wide range of deflections. Their deflection curves have a wider, flatter linear force region than either coil or disc springs. Wave springs transmit those spring forces only in the intended axial direction. They don’t suffer from the torsional loading and twisting that can make conventional coil springs less effective.

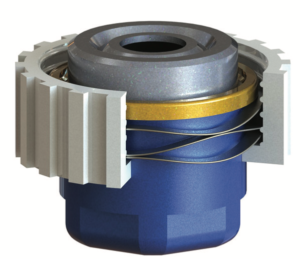

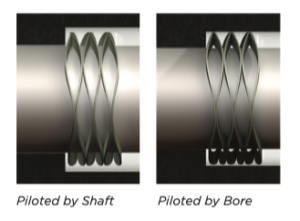

In addition to their favorable force characteristics, wave springs have assembly advantages. Many wave springs have the ability to self-locate in bored holes or on shafts. And a single multi-turn wave spring can frequently replace an entire stack of disc springs, eliminating an assembly step.

As drop-in replacements for traditional spring elements, wave springs can improve the performance of spring- loaded components. But to maximize the engineering potential of wave springs, you should design around their unique qualities, which include:

Axial Space Savings. The most immediately noticeable quality of wave springs is just how much axial space they can save. In static applications, a wave spring will typically need just 50% of the work height of coil spring to deliver an equivalent force. In dynamic applications, the work height advantage is typically about 30%, less than static applications but still substantial. The reason for the difference comes down to the fundamentals of multi-turn wave spring design. To minimize the bending stresses in dynamic applications, the wave spring will typically require more turns than in a static application. And more turns result in additional work height.

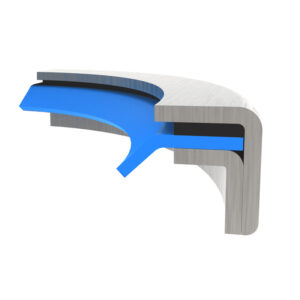

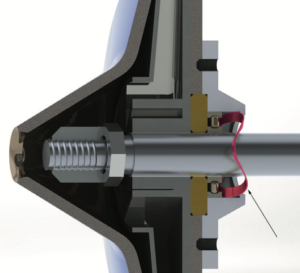

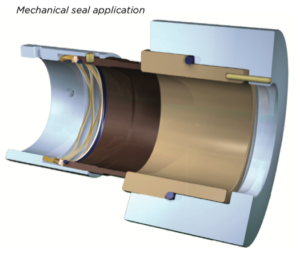

Consistent Spring Force. Spring elements typically exhibit both linear and non-linear force behaviours, depending on their deflection. This linear behaviour can be graphically shown on the spring’s load- deflection curve. In general, the broader and flatter linear region of the curve, the easier it is to hit specific spring force requirements. Wave springs have a clear advantage in this department. They typically have a linear force between 30 and 70% deflections. Both coil and disc spring have much narrower linear force regions (See Figure 1). Predictable spring forces can be a big benefit in many applications. Mechanical seals, for example, successfully use wave springs to preload the sealing surfaces. Having a predictable spring force allows the seal designer to strike the balance between excess wear from too high a preload and leaks from too low a preload.

Dimensional Tolerances Improvements. A side benefit of a wave spring’s predictable forces involves dimensional tolerances for the cavities and shafts that hold spring elements. These tolerances are often driven by the need to accommodate the spring’s force-to-work height requirements. By specifying wave springs whose force is relatively consistent across a range of deflections, it’s often possible to loosen dimensional tolerances on spring cavities and shafts. This ability represents a major, but often overlooked, cost factor in favour of wave springs.

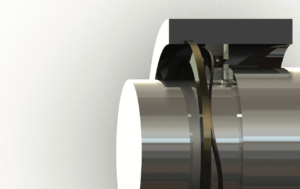

No Torsional Loads. Whenever you compress a coil spring to its work height, loads are not just in the axis of compression but also torsional. These torsional loads can cause the pre-loaded component to rotate in use, potentially resulting in excess wear. Torsional loads can also decrease the spring’s working load. Many applications, including seals, can suffer from this rotational wear problem. Wave springs don’t have this issue. Their wave forms can only compress axially, in some cases changing their diameter slightly.

Increased Travel. When compared to a traditional disc spring, multi-turn wave springs offer far more travel. A single multi-turn wave spring can easily replace the assemblies the use multiple disc springs to achieve the necessary travel. Most applications require relatively short travel distances, usually less than 1 mm. But to give you an idea of what’s possible, we’ve engineered multi-turn wave springs that offer up to 50-mm of travel. Replacing a stacked disc spring assembly with one wave spring can result in both cost and quality benefits. Not only will the single spring cost less to install than the stacked disc springs, but it also reduces the chance that the the wrong number of disc springs will make it into a finished assembly.

Dial in Required Stiffness. Wave spring stiffness is determined by thickness and type of spring material as well as by the number of waves per turn of spring. You can easily dial in a required stiffness by optimizing the number of waves per turn using well-known design formulas (see Sidebar). Increasing the number of waves per turn does have an influence on free height and compressed diameter of the wave spring. More turns also increases the hysteresis since each waves has some friction associated with it. All these effects are easily offset. You can account for free-height and diameter effects during design. And hysteresis can be eliminated by presenting the wave spring—that is, compressing to its work height over several cycles.

Fast Customization. Unlike stamped produces, which require tooling, wave springs can be customized on the fly—by changing the parameters of the coiling equipment. This ability allows you to specify custom wave springs without worrying about cost or delays associated with custom tooling. This capability is yet another cost factor weighing in favour of wave springs.

WAVE SPRINGS ARE NOT CREATED EQUAL

All the advantages we’ve laid out for wave springs assume that the springs are made from high-quality materials, manufactured in a controlled environment and properly designed for the application at hand. Our wave springs are produced in a vertically integrated manufacturing environment—in which we roll our own flat wire and form it in our own machines. Vertical integration allows to adjust to batch to batch variations in our raw materials, which include a variety of steels and other alloys. It also allows us to keep tight statistical control on all the rolling and coiling processes.

When it comes to wave springs, the importance of this manufacturing expertise can’t be understated. Even small variations in wire thickness, wave geometry or metallurgy can all have drastic effects on a wave spring’s performance in the field. Force characteristics in particular can suffer if the spring hasn’t been made properly. So it pays to specify high-quality springs. If you do, you’ll be able to take advantage of all the design benefits waves springs can offer.

Check out the Formulas for Spiral Wound Wave Springs here.

To learn about selecting the correct products for your operating environment please contact your local Daemar Technical Sales Representative.