Home >> Seal >> Trelleborg Sealing Solution >> Turcon® Variseal® >> Hardware Design Considerations

Hardware Design Considerations

The best way to obtain optimum Variseal ® performance is to plan ahead during the design phase of your product. The initial phase should bring into alignment the three factors having the greatest impact on seal performance – the hardware design, the service conditions, and the seal design.

Design issues such as gland style, mating surface hardness and surface finish, and dynamic alignment should be reviewed and adjusted to work with the intended service conditions and to suit the selected seal design. The information in this section is primarily intended as a guide for the design of new hardware, however, it is completely applicable to the task of reviewing or modifying existing hardware to improve seal performance.

A primary goal in selecting a basic gland style is to be able to install the seals without damaging them. The first half of this section describes the various gland types and installation procedures.

Once the issue of seal installation has been addressed, the goal of hardware design is then to improve seal performance in terms of wear life, leakage rate, friction, and so on.

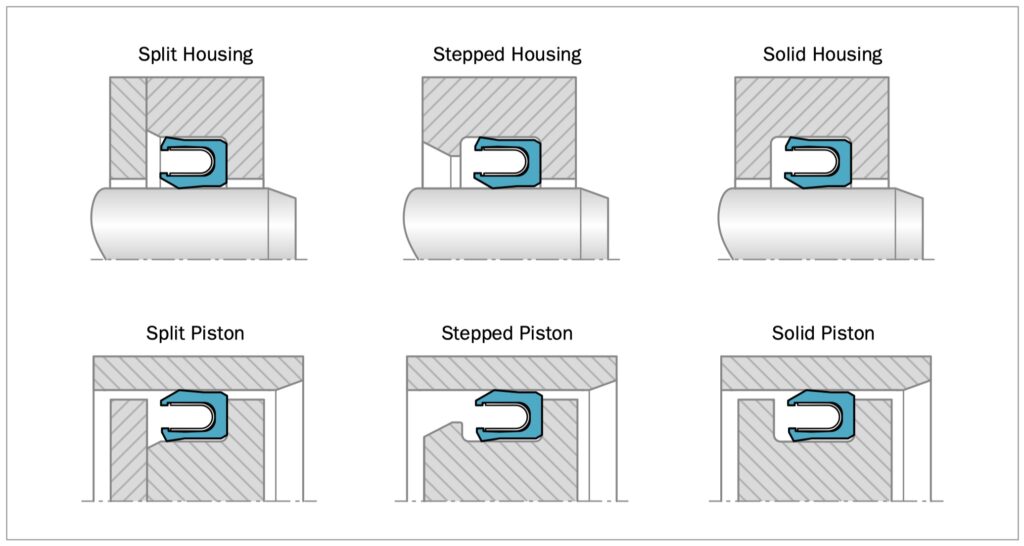

Basic Gland Styles

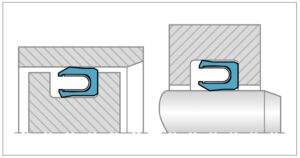

There are three basic gland styles to be considered – split, stepped, and solid (see Figure below). The gland required for a radial Variseal ® is similar to an O-Ring gland with one major difference – an O-Ring gland has a typically solid (one piece) construction with a full gland wall on each side. Since the Variseal ® is made from polymers, which do not stretch like elastomers, installation in such glands can be difficult – or in many cases impossible. To install the Variseal ® easily requires either the split gland or the stepped gland. The solid groove is sometimes used, but only when no other option exists and then only with certain diameter restrictions described later in the Groove Design section.

When retrofitting an existing solid gland for which the hardware cannot be modified, the solution might involve a special seal design or installation tools. Our engineering and technical support personnel are always available to assist you with these situations. To discuss your application, please contact your local Customer Solution Center.

The basic gland styles shown above are described in further detail below.

Basic Gland Types

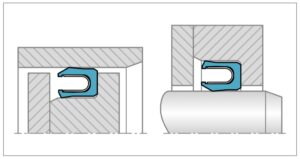

Split Gland

The best way to obtain optimum Variseal ® performance is to plan a split gland. A split gland designates hardware that is separated or “split” into two pieces to allow assembly without deforming the seal. The split gland minimizes potential damage to the seal. Its advantages include:

- No stretching of the seal

- Repeated installation without damage

- No special installation tools

The disadvantage is that a second piece such as an end plate is required to retain the seal. This might also involve a third piece such as a bolt to secure the end plate.

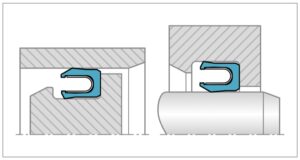

Stepped Glands

A stepped gland has a small “step” or ledge, which retains the seal. The step height is small, so that the seal can be pushed past it easily. See the Groove Design section for recommended step heights. In most cases, no special tooling or installation procedures are required.

The stepped gland has the advantage of being a simpler configuration (with fewer pieces than the split gland) while maintaining relative ease of assembly. The stepped gland is an excellent configuration for piston seal applications.

Solid Glands

Because the Variseal ® does not stretch like an elastomeric O-Ring, it is difficult to install in a solid radial groove. This gland is not recommended for new designs, but is often encountered when retrofitting existing glands. It can be used in cases where the ratio of seal diameter to seal cross-section is large enough.

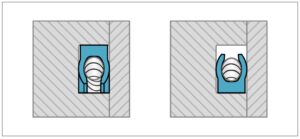

Face Seal Glands

Face seal glands for the Variseal ® are typically the same as O-Ring glands, with no problems installing the seal. One advantage of the Variseal ® in face seal applications is that it does not require a full gland wall on the pressure side of the seal.