Home >> Seal >> Trelleborg Sealing Solution >> Trelleborg Aircraft Seals & Aerospace Seals >> AIRCRAFT MIL GROOVES

AIRCRAFT MIL GROOVES

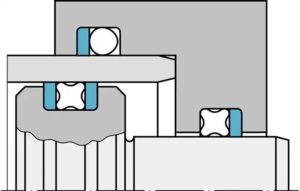

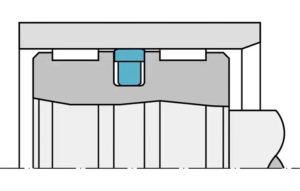

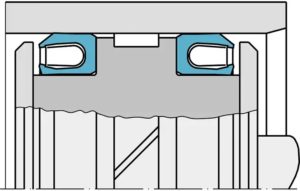

Back-up Ring | Aircraft MIL Grooves | Trelleborg

Back-up Ring | Aircraft MIL Grooves | Trelleborg

Features: Reciprocating and Static

| Ø – Range | Pressure Range | Temp. range | Velocity |

|---|---|---|---|

| 0.5 mm | 200 MPa | -60°C +200°C | 0.5 m/s |

| 0.02 in | 29000 psi | -75°F +390°F | 1.6 ft/s |

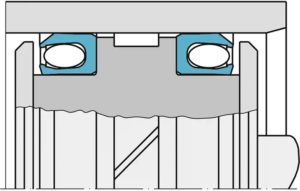

Grooved Turcon® Plus Seal® II | Aircraft MIL Grooves | Trelleborg

Grooved Turcon® Plus Seal® II | Aircraft MIL Grooves | Trelleborg

Features: Reciprocating

| Ø – Range | Pressure Range | Temp. range | Velocity |

|---|---|---|---|

| – | – | – | – |

| – | – | – | – |

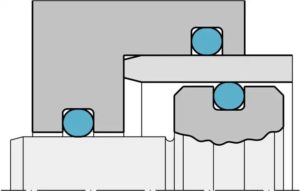

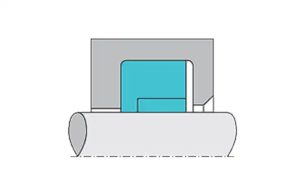

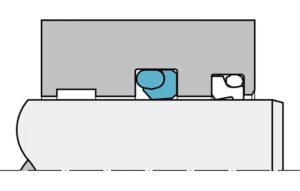

Aircraft O-Ring | Aircraft MIL Grooves | Trelleborg

Aircraft O-Ring | Aircraft MIL Grooves | Trelleborg

Features: Helix, Oscillating, Reciprocating and Static

| Ø – Range | Pressure Range | Temp. range | Velocity |

|---|---|---|---|

| 0.5 mm | 200 MPa | -60°C +200°C | 0.5 m/s |

| 0.02 in | 29000 psi | -75°F +390°F | 1.6 ft/s |

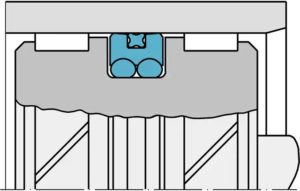

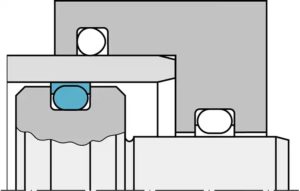

Turcon® AQ Seal® 5 | Aircraft MIL Grooves | Trelleborg

Turcon® AQ Seal® 5 | Aircraft MIL Grooves | Trelleborg

Features: Reciprocating

| Ø – Range | Pressure Range | Temp. range | Velocity |

|---|---|---|---|

| 40 – 700 mm | 60 MPa | -30°C +200°C | 3 m/s |

| 1.5 – 27.5 in | 8700 psi | -22°F +390°F | 10 ft/s |

Turcon® CX(D) Seal | Aircraft MIL Grooves | Trelleborg

Turcon® CX(D) Seal | Aircraft MIL Grooves | Trelleborg

Features: Reciprocating

| Ø – Range | Pressure Range | Temp. range | Velocity |

|---|---|---|---|

| – | – | – | – |

| – | – | – | – |

Turcon® CX(S) Seal | Aircraft MIL Grooves | Trelleborg

Turcon® CX(S) Seal | Aircraft MIL Grooves | Trelleborg

Features: Reciprocating

| Ø – Range | Pressure Range | Temp. range | Velocity |

|---|---|---|---|

| – | – | – | – |

| – | – | – | – |

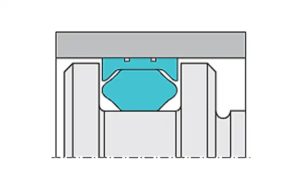

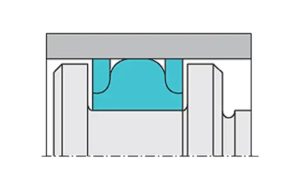

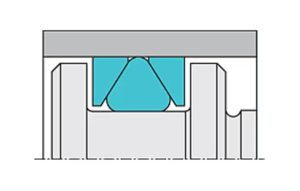

Turcon® Double Delta® II | Aircraft MIL Grooves | Trelleborg

Turcon® Double Delta® II | Aircraft MIL Grooves | Trelleborg

Features: Reciprocating

| Ø – Range | Pressure Range | Temp. range | Velocity |

|---|---|---|---|

| 4-2,700 mm | 35 MPa | -45°C +200°C | 15 m/s |

| 0.157-105 in | 5075 psi | -50°F +390°F | 50 ft/s |

Turcon® T-Seal | Aircraft MIL Grooves | Trelleborg

Turcon® T-Seal | Aircraft MIL Grooves | Trelleborg

Features: Reciprocating

| Ø – Range | Pressure Range | Temp. range | Velocity |

|---|---|---|---|

| – | – | – | – |

| – | – | – | – |

Turcon® Variseal® M2 | Aircraft MIL Grooves | Trelleborg

Turcon® Variseal® M2 | Aircraft MIL Grooves | Trelleborg

Features: Helix, Oscillating, Reciprocating and Rotary

| Ø – Range | Pressure Range | Temp. range | Velocity |

|---|---|---|---|

| 3 – 3,300 mm | S:40 D:20 MPa | -70°C +300°C | L: 15 R/O/H: 1.3 m/s |

| 0.118 – 130 in | S:5,800 D:2,900 psi | -95°F +570°F | L: 50 R/O/H: 4.2 ft/s |

Turcon® Variseal® W2 | Aircraft MIL Grooves | Trelleborg

Turcon® Variseal® W2 | Aircraft MIL Grooves | Trelleborg

Features: Reciprocating

| Ø – Range | Pressure Range | Temp. range | Velocity |

|---|---|---|---|

| 3 – 3,300 mm | S:40 D:20 MPa | -70°C +300°C | L: 15 R/O/H: 1.3 m/s |

| 0.118 – 130 in | S:5,800 D:2,900 psi | -95°F +570°F | L: 50 R/O/H: 4.2 ft/s |

Turcon® VL Seal® | Aircraft MIL Grooves | Trelleborg

Turcon® VL Seal® | Aircraft MIL Grooves | Trelleborg

Features: Reciprocating

| Ø – Range | Pressure Range | Temp. range | Velocity |

|---|---|---|---|

| 6 – 2,600 mm | 60 MPa | -45°C +200°C | 15 m/s |

| 0.236 – 102 in | 8700 psi | -50°F +390°F | 50 ft/s |

Turcon® Wedgpak® | Aircraft MIL Grooves | Trelleborg

Turcon® Wedgpak® | Aircraft MIL Grooves | Trelleborg

Features: Reciprocating

| Ø – Range | Pressure Range | Temp. range | Velocity |

|---|---|---|---|

| – | – | – | – |

| – | – | – | – |