Home >> Blog >> Retaining Rings, the Essential Components that Save Cost & Increase Efficiency

Retaining Rings, the Essential Components that Save Cost & Increase Efficiency

Retaining rings carry out an essential purpose irrespective of the kind of application they are utilized in. Don’t let its small size deceive the importance of these components, as not only do they increase the efficiency of an application but they are also responsible for absorbing vibration, splitting tolerances and optimizing the manufacturing assembly line to save costs.

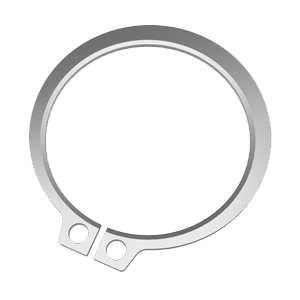

The main purpose of a retaining ring is to hold various components onto a shaft or into a bore. The smooth, round finish of most shafts or bores makes them hard to fasten with alternative means while retaining rings easily clamp around them, creating a shoulder that secures parts in place. This shoulder provides the retaining rings with their functionality and allows them to be installed around the exterior of a shaft or inside a bore.

On the plus side, these components can replace traditional fasteners effectively, putting aside the need for threading, tapping, drilling and other machining processes linked with traditional fasteners like screws, nuts, bolts, washers and more.

They are known greatly reduce production costs as the grooves can be machined with other production processes. Thus, making use of these components is a win-win.

Advantage

Some of the advantages of retaining rings over traditional fasteners include:

- Helps to save costs on raw material and labour

- Reduces the weight and size of finished machine/equipment

- Saves time as shaft/housing preparation is minimal

Uses of Retaining Rings

The retaining ring is one of the most widely used components. Whether manufacturing airplanes or essential biomedical machines, they are an essential component for these products to function correctly. Let’s take a look at their application in some of the industries:

Food & Beverage Industry

During food and beverage processing the product often moves through many filtration processes in order to remove impurities. To achieve the required level of filtration there are many filters installed throughout the manufacturing equipment. The appropriate material and size Retaining Ring is often the method of choice to hold these filters in place. Retaining rings are easy to install and can aid with the alignment of the filters.

Medical Industry

Due to their small size and availability in stainless steel and other special alloys, retaining rings can lend themselves to utilization in surgical instruments, imaging devices and implants. Moreover, they don’t have gaps or lugs making them ideal for tight radial applications.

Automotive Industry

The cars we use today can’t function without the help of retaining rings. They are present in many major and minor components of automobiles. Whether you think of Lifesaving airbags or smooth functioning gear transmission systems, retaining rings play a major role in their functioning. Some of the components where retaining rings are present include: gearboxes, rearview mirrors, steering system, brake pedal assemblies, valves etc.

Oil & Gas Industry

Like other industry applications, retaining rings are very popular in Oil & Gas Industry. Retaining Rings are used in Ball Valves, Gate Valves, Coiled Tubing, Electronic Chassis & Delivery Tools. Often oil and gas industry applications involve extreme environmental conditions, retaining rings are also manufactured in a range of special materials which can withstand these harsh conditions.

The sky is the limit for retaining ring applications, and Daemar is here to help you achieve your goals. With dozens of standard styles and the flexibility of Custom designs, Daemar® Inc. has teamed with a world-class supplier to offer you one-stop shopping for your fastener requirements. To check the range of retaining rings we offer, visit our retaining rings page.

Selecting the right retaining ring for your application can be a tricky process due to a lot of technicalities, but Daemar’s expert team can help you make the right decision. To learn about selecting the correct retaining ring for your operating environment, please contact your local Daemar Technical Sales Representative.