Home >> Blog >> Maximizing Equipment Performance in the Semiconductor Industry: Turcon® Varilip® PDR

Maximizing Equipment Performance in the Semiconductor Industry: Turcon® Varilip® PDR

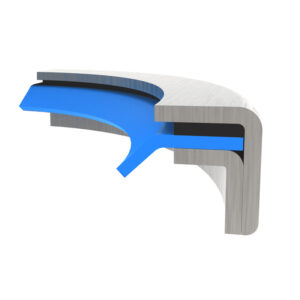

One of the primary features of Trelleborg’s Turcon® Varilip® PDR (Performance, Durability, Reliability) is their ability to operate at

high speeds and under demanding conditions. It is achieved using high-performance materials such as PTFE which are mechanically retained in a precision-machined metal body and are resistant to chemicals, high temperatures, and aggressive media. Additionally, the seals are designed to provide low-friction and stick-slip-free running, which helps to reduce temperature generation, permit higher peripheral speeds and lower power consumption.

.

.

Tests show that Turcon® Varilip® PDR requires only around 50 percent of the torque of a radial oil seal when running in Fomblin® oil, commonly used in semiconductor vacuum pumps. It results in long service life, with a maximized mean time between planned maintenance and greater productivity.

Benefits of Turcon® Varilip® PDR seals include:

- Low friction to facilitate reduced power loss and friction-induced heat

- Unique self-lubricating hydrodynamic feature to further reduce friction

- Advanced geometries engineered to give excellent performance in almost every high-speed rotary situation

- Multiple lip configurations to address most sealing needs

- Material compatible with virtually all media

- High-speed capability up to 100 meters per second / 19,680 feet per minute

- Wide operating temperature range from -60 °C to +200 °C / -76 °F to 392 °F

- Options available for dry-running applications and soft shafts

- Unlimited shelf life with no special storage requirements

In conclusion, Trelleborg Turcon® Varilip® PDR is a must-have for the semiconductor industry. Its unique design, excellent performance, and high resistance to demanding conditions make it the perfect solution for any application that requires a high-performance seal. They are a perfect fit for design engineers looking for reliable, precise and long-lasting solutions for their equipment. Learn more about Trelleborg Seals’ Varilip® PDR and other rotary seals.