Home >> Seal >>O-Rings >> Kalrez O-Rings >> Kalrez Photovoltaic Manufacturing Seals

Kalrez® Photovoltaic Manufacturing Seals

Photovoltaic Manufacturing Seals Help Improve Uptime

Kalrez® seals can help increase uptime and raise production quantity and quality in bulk crystalline silicon and thin-film photovoltaic processes.

DuPontTM Kalrez® perfluoroelastomer partsresist over 1,800 chemicals andoffer excellent thermal stability, making them an appropriate choice for photovoltaic cell manufacturing.

DuPont™ Kalrez® Perfluoroelastomer (FFKM) parts provide the highest levels of chemical resistance, outstanding thermal & steam resistance and low contamination from extractables for demanding applications in the life sciences sector where FDA compliance is required.

Kalrez® parts deliver optimal sealing solutions through longer seal life versus lower performing elastomers, cleanliness, and high levels of resistance to chemicals and high temperatures. They are resistant to 1800 chemicals and solvents and retain high levels of elasticity and recovery, even after long-term exposure to elevated temperatures. All this results in longer, more effective performance and increased safety and efficiency in production.

Performance in Cell Manufacturing

Kalrez® W240 and 9100 parts for photovoltaic cell manufacturing offer excellent resistance to both chlorine and fluorine gas, as well as other dry-process chemistry. The seals have excellent mechanical strength properties, and are well-suited for both static and dynamic sealing applications.

The performance properties of Kalrez® seals can help improve reliability, leading to more consistent photovoltaic manufacturing quality, and also more efficient production, with the potential for less down-time.

Chemical Resistance

The aggressive chemicals used in many photovoltaic manufacturing processes can affect the sealing performance of elastomers. Choosing Kalrez® W240 parts as an upgrade over fluoroelastomers and silicone can help prevent or reduce unplanned maintenance and safety incidents as a result of incompatible sealing materials.

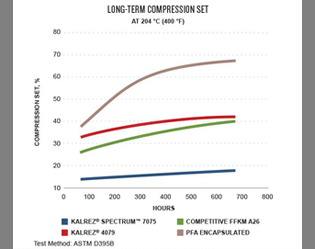

Thermal Stability

With heat resistance to temperatures of up to 325O C, Kalrez® PV8070 parts have been designed to incorporate properties that take the heat where fluoroelastomer (FKM) and silicone (VMQ) under-perform. In a comparison of PV8070, FKM and VMQ for over 336 hours at 250°C, Kalrez® seals maintained excellent recovery properties. FKM and VMQ completely lost resilience after 336 hours.

Features