Home >> Blog >> Important Things to Consider When Choosing Masking Products for the Industrial Applications

Important Things to Consider When Choosing Masking Products for the Industrial Applications

Highly finished products make all the difference in the appearance of the final product, thus creating a positive image of the product in the customers’ mind. It saves a lot of time and effort when a product is finished with masking compared to a product finished without masking, as cleaning up paint or powder where it doesn’t belong is a hard process.

The masking product you select should offer these characteristics for an effective and high-quality finish along with protecting your products from damage:

- Ability to tolerate high-temperature environments: Several industries, especially the automotive industry, perform operations in high-temperature environments. Masking products should retain their shape and form in high temperatures for a properly finished end product.

- Easy Removability: The masking products should be easily removable so that they do not damage the end product or leave any residue on their surface. Any damage or residue will negatively impact the appearance, defeating the purpose of masking.

- Clean and effortless tearing: When it comes to masking tapes, they should be easy to tear. It helps in a neater finish and saves time.

- Cost-Effective: The masking product that suits your finishing industry needs to be inexpensive so that it doesn’t add substantial costs to finish your products.

Daemar offers a complete line of masking products for the finishing industry. Our standard product line consists of caps, plugs, stoppers, tapes, tubing and sheeting. This product is available in a range of materials that include Silicone, EPDM and High-Temperature Vinyl. In addition, Daemar can provide custom solutions with custom moulded parts, and custom dies as well as custom kits. Contact us for a custom solution.

Masking Caps

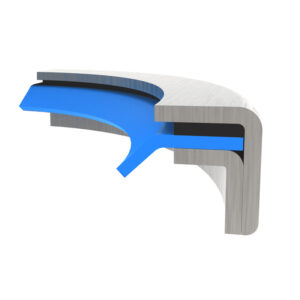

Masking Caps: Our standard product line of masking caps is available in a range of materials that include: Silicone, EPDM, Paper, and High-Temperature Vinyl.

Masking Plugs

Our standard product line of masking plugs is available in a range of materials that include: Silicone, EPDM, Cork, and High-Temperature Vinyl.

Masking Tapes

Our standard product line of masking tapes is available in a range of materials that include: Polyimide, Polyester, Crepe, Glass Cloth and Silicone Rubber.

Masking Die Cuts

Our standard product line of masking die cuts is available for a range of applications with materials that include: Aluminum Foil, Electroplaters vinyl, Glass Cloth, Polyimide, Polyester, Lead Foil, and Teflon.

You can also review our masking hooks guide if you require masking hooks and want to make the correct selection.

To get more information about Daemar’s range of masking products, contact your local Daemar Technical Sales Representative.