Home >> Blog >> How to Choose Between Slotted Shims, Shim Rolls, and Custom Shim Sheets for Precise Machinery Alignment

How to Choose Between Slotted Shims, Shim Rolls, and Custom Shim Sheets for Precise Machinery Alignment

Misalignment is one of the leading causes of machinery breakdowns. Even a tiny height variation under a motor foot can create soft foot, causing vibration, energy loss, and premature failure of bearings or seals. Shims are the simple but critical solution—yet many teams struggle to pick the right type.

This blog breaks down the pros, cons, and best uses of slotted shims, shim rolls, and custom shim sheets, helping you decide the best fit for your equipment and maintenance strategy.

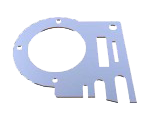

Slotted Shims: Speed and Precision

What they are:

Pre-cut stainless steel “horseshoe” shaped shims that slip under machine feet without removing hold-down bolts.

Best for:

- Quick, repeatable alignments in pumps, fans, compressors, gearboxes, and motors

- Maintenance crews that need organized, ready-to-use kits

Advantages:

- Insert/remove without disassembly – saves hours during shutdowns

- Manufactured to tight tolerances (as low as ±0.00008″)

- Kits come organized by size and thickness with removal tools for safety

- Reduce soft foot risk by using fewer, thicker shims rather than stacking many thin ones

Watch-outs:

- Fixed sizes may not cover non-standard bolt patterns

- Stacking more than 3–4 shims under one foot can reduce stability

Daemar’s advantage: Offers stainless steel slotted shim kits (A–H sizes, .001″–.125″ thicknesses) with rugged cases, Shim Lock, and removal tools.

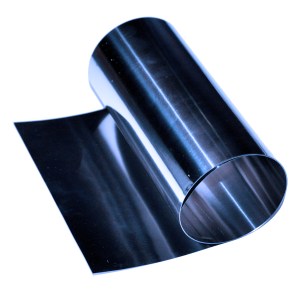

Shim Rolls & Sheets: Flexibility On-Demand

What they are:

Rolled or sheet stock in various metals and plastics, available in different sheet thicknesses, can be cut to any required shape.

Best for:

- Custom or odd-shaped machine feet

- Facilities needing a broad range of shim options on hand

- Low-volume or non-time-sensitive jobs

Advantages:

- Wide material choices: stainless, brass, steel, aluminum, copper, plastic

- Thicknesses from ultra-thin (.0005″) to medium (.032″)

- Cost-effective if you need occasional custom sizes

Watch-outs:

- Cutting on-site can introduce burrs or inconsistent thickness – leading to poor alignment

- Labor-intensive compared to pre-cut shims

Daemar’s advantage: Carries shim rolls in multiple materials with clear labeling, boxed packaging, and easy handling for shop or field use.

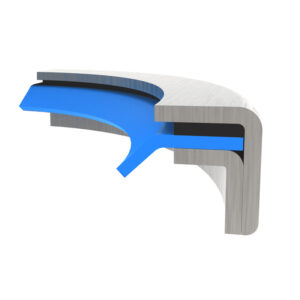

Custom Shim: Precision Without Compromise

What they are:

Shims manufactured to your exact dimensions, thickness, and material requirements.

Best for:

- Complex bolt patterns

- High-value machinery where downtime costs a lot of money

- Harsh environments (corrosive, high-temp, chemical exposure)

Advantages:

- Perfect fit eliminates the need for on-site modifications

- Wide choice of materials: stainless, brass, steel, polyester film, polypropylene, and more

- Reduces installation errors and ensures precision & reliability

Watch-outs:

- Higher upfront cost than standard kits or rolls

- Lead time (though Daemar delivers quotes in 24–48 hrs, with most orders in 2–3 weeks)

Daemar’s advantage: Precision manufacturing to top industry standards, with custom packaging and labeling that make inventory and installation effortless.

Quick Comparison Table

| Application Need | Best Choice | Why |

| Fast, precise maintenance alignments | Slotted Shims | Pre-cut, tight tolerance, organized kits |

| Variety & flexibility for unique shapes | Shim Rolls/Sheets | Cut-to-size versatility, many material options |

| Critical precision & unique requirements | Custom Shims | Tailored, ready-to-install, no on-site cutting |

Key Factors in Choosing the Right Shim

- Time Sensitivity – If downtime is costly, pre-cut slotted shims save the most time.

- Machine Geometry – Odd bolt patterns? Shim rolls or custom shims fit better.

- Environment – Corrosive or chemical exposure? Stainless steel or plastic may be required.

- Thickness Needs – Rolls provide ultra-thin options; custom shims cover precise dimensions.

- Budget vs Risk – Rolls may be cheaper up front, but slotted/custom shims prevent costly misalignment errors.

Best Practices for Alignment Success

- Limit stacking: Use no more than 3–4 shims under a foot—replace with thicker options instead.

- Clean surfaces: Dirt or paint under shims throws off precision.

- Measure accurately: Verify thickness with calipers, don’t just trust labels.

- Match shim size to bolt diameter: Prevents bending or stress during torque.

Final Thoughts

Shims may be small, but they have a big impact on the health of rotating machinery.

- Use slotted shims for speed and reliability.

- Keep shim rolls for on-the-spot flexibility.

- Invest in custom shims when precision and downtime savings matter most.

By matching the shim type to your alignment needs, you’ll extend equipment life, reduce vibration, and save costs long term.

Explore Daemar’s full Align Components lineup here.