Home >> Seal >>O-Rings >> Kalrez O-Rings >> Kalrez High-Heat And-Fuel Resistant Aircraft Engine Seals

Kalrez® Aircraft Engine Seals

High-Heat And-Fuel Resistant Aircraft Engine Seals

Kalrez® O-rings and seals combine the chemical and thermal stability of a fluoropolymer with the seal resilience of an elastomer.

DuPont™ Kalrez® perfluoroelastomer parts began being selected broadly for aircraft engine seals with the commercialization of Kalrez® 4079AMS to meet AMS 7257 specification in the 1980s.

Now, DuPont continues to develop its product offering, developing more elastomers and formulations that have been demonstrated to provide exceptional performance within aerospace and aircraft engine applications.

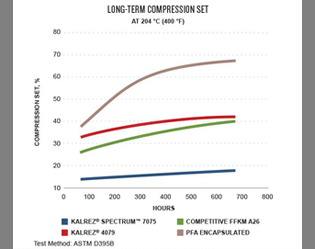

The properties of Kalrez® parts have helped provide time tested reliability for aerospace seals and O-rings, which must withstand high temperatures, corrosive fuels and lubricating oils. The durability of Kalrez® aerospace seals can help minimize unscheduled downtime, for longer meantime between repair, and reduce overall operating costs.

Proven Durability

Kalrez® seals are formulated to provide exceptional performance in aerospace and aircraft engine applications. Kalrez® AeroSealTM 7777 and 7797 parts were successfully tested for over 8000 hours by a major equipment maker, putting parts in contact with high thermo-oxidative stability lubricants. Both products exhibit excellent High Thermo-oxidative Stability (HTS) resistance. With a maximum continuous service temperature of 325º C (617º F), Kalrez® AeroSeal™ 7777 and 7797 demonstrated low compression set, improved stress relaxation and improved temperature cycling performance.

The latest product for aircraft and aerospace engines is Kalrez® AeroSeal™ 7800 parts. The parts provide ultra-low titanium corrosion and low compression set. Kalrez® 7800 parts meet AMS 7257D.

Engineered for Aerospace Applications

Kalrez® parts are engineered with properties that withstand aggressive aerospace fluids, including jet fuels, engine lubricating oils, hydraulic fluids, rocket propellants and oxidizers. They exhibit excellent sealing performance and mechanical properties for both static and dynamic applications.