Home >> Shaft Seals >> JM Clipper Seals >> JM Clipper Material

JM Clipper Material for Seals

JM Clipper Oil Seals are available in a wide range of materials. The following general material descriptions are for the OD material “H” and corresponding lip material “L”.

OD and Lip Materials

H1L5 & H1L7 — Nitrile (NBR)

Standard Nitrile is the most commonly used polymer in the rotary shaft seal industry. NBR has very good resistance to oil, fuel and alkali solutions. Nitrile offers excellent resistance to petroleum-based hydraulic fluids and is resistant to hydrocarbon solvents. Standard Nitrile has poor resistance to ozone, ketones, automotive or aircraft brake fluid, and steam or hot water. Standard Nitrile is recommended for operating in temperatures ranging from -20 to +250 °F (-29 to +121 °C) and offers good mechanical properties and abrasion resistance.

H1L50 & H1L70 — Low Temp Nitrile (NBR)

Nitrile compounds can be formulated for applications in extreme cold weather environments. These special formulations of Nitrile allow for operation at minimum temperatures ranging down to -70 °F (-57 °C), while maintaining good chemical and abrasion resistance, but the upper temperature limit is lowered to 212 °F (100 °C).

H1L20 — Carboxylated Nitrile (XNBR)

XNBR is formulated to greatly enhance tear and abrasion resistance over standard Nitrile, while maintaining similar chemical compatibility. It is used in applications where abrasive materials may collect at the point of shaft contact. XNBR is less resilient and flexible at low temperature, and offers poorer compression set resistance than standard Nitrile. Carboxylated Nitriles are recommended for operation at temperatures ranging from -30 to +250 °F (-34 to +121°C).

H1L30 — Hydrogenated Nitrile (HNBR)

Hydrogenated Nitriles offer improved abrasion resistance, excellent chemical resistance and higher operating temperatures than standard NBR. Ozone and weather resistance, as well as resistance to hot water are also increased. HNBR compounds are recommended for operating temperatures ranging from -40 to +300 °F (-40 to +149 °C).

H1L8 — Neoprene (CR)

Neoprene offers very good resistance to weather, ozone and natural aging as well as good flame resistance while maintaining moderate resistance to oil and gasoline. Good abrasion, flex and cracking resistance is available with the Neoprene material. Neoprene is recommended for operating temperatures ranging from -45 to +250 °F (-43 to +121 °C).

H1L21 — Ethylene Propylene (EPDM)

EPDM offers excellent heat, ozone and sunlight resistance. EPDM offers very good low temperature flexibility, good resistance to alkalis, acids (such as acetic), and oxygenated solvents (such as MEK). Provides improved resistance to water and steam in applications where NBR and FKM exhibit poor service life. Good replacement for FKM where solvents are a problem. It is not recommended for petroleum oil. EPDM is recommended for operating temperatures of -60 to +300 °F (-51 to +149°C).

H5L16 — Fluoroelastomer (FKM)

FKM provides excellent resistance to oils, fuels and hydraulic fluids at temperatures that far exceed standard Nitrile. It also has very good resistance to flame and excellent impermeability to gases and vapors. FKM is recommended for operating temperatures that range from -40 to +400 °F (-40 to +204 °C).

Case Materials

H1, H3 — Neoprene/Aramid Composite

The aramid fiber-reinforced composite shell will fit a wide range of bore tolerances and provides a rustproof gasket-type seal at the OD. The composite case also will fill slight imperfections in the bore housing, reducing machining cost. Usually combined with a Nitrile lip material.

H5 — Fluoroelastomer/Aramid Composite

Offers the same construction benefits mentioned above. Usually combined with a Fluoroelastomer lip material.

Spring Materials

Clipper Oil Seal designs are furnished with 302 stainless steel springs as standard. Other spring materials are available at an additional cost.

| Wire Type | Max Service Temperature (°C) |

Max Service Temperature (°F) |

Application |

|---|---|---|---|

| Carbon Steel | 120 | 250 | General purpose |

| Monel 400 | 230 | 450 | Saltwater |

| Inconel 750 | 675 | 1250 | Extreme temperature |

| Phosphor Bronze | 95 | 200 | Saltwater |

| 302/304 Stainless Steel | 260 | 500 | Corrosion resistance |

| 316 Stainless Steel | 315 | 600 | Hi-temp corrosion resistance |

Spring Type

For lip loading, the Clipper Oil seal uses a coil wire spring (garter spring).

Garter spring benefits:

• Provides a more uniform load to sealing lip

• Heat treated — stress relieved

• Constant load with minimum load variations

• Able to adjust the spring in the field to increase load

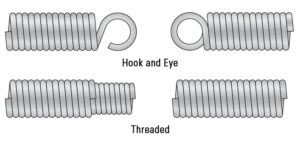

Two types of spring connections are used:

1. Threaded type is used on most solid seals.

2. Hook and eye type are used on splits seals because they are easier for the end user to connect during installation.

Clipper Oil Seal Standard Material

| Matl. Code Case/Lip |

Material Description | Abrasion Resistance |

Min. Temp |

Cont. Temp |

Peak. Temp |

|---|---|---|---|---|---|

| H1L5 | Nitrile (75 Duro NBR) Standard NBR offering.

The NBR lip material has very good resistance to oil and gasoline. Superior resistance to petroleum-based hydraulic fluids. Good resistance to hydrocarbon solvents. Very good resistance to alkalis and solvents. Poor resistance to oxygenated solvents. |

Very Good | -20 °F

-29 °C |

212 °F

100 °C |

250 °F

121 °C |

| H1L7 | Nitrile (85 Duro NBR)

The L7 lip material has a lower minimum temperature capability than the L5 material. |

Very Good | -30 °F

-34 °C |

212 °F

100 °C |

250 °F

121 °C |

| H1L20 | Carboxylated Nitrile (83 Duro XNBR)

The XNBR lip material is generally tougher and more resistant to tear and abrasion than standard NBR. |

Outstanding | -30 °F

-34 °C |

212 °F

100 °C |

250 °F

121 °C |

| H1L30 | Hydrogenated Nitrile (75 Duro HNBR)

The HNBR lip material offers improved abrasion resistance, chemical resistance, higher operating temperature and better ozone resistance than standard NBR. |

Outstanding | -40 °F

-40 °C |

250 °F

121 °C |

300 °F

149 °C |

| ALLL5 | Nitrile (75 Duro NBR)

Homogenous NBR material without aramid fiber OD provides a very pliable seal that can be stretched over flanges or other obstructions on the shaft. A cover plate is recommended to keep the seal retained in the housing bore. |

Very Good | -20 °F

-29 °C |

212 °F

100 °C |

250 °F

121 °C |

| H1L50 | Arctic Nitrile (85 Duro Low Temp NBR)

Low temperature Nitrile lip material allows for lower minimum temperatures while providing good chemical and abrasion resistance. |

Very Good | -50 °F

-46 °C |

200 °F

93 °C |

212 °F

100 °C |

| H1L70 | Alaska Nitrile (75 Duro Low Temp NBR)

Same characteristics as L50, but softer with lower minimum temperature range. |

Very Good | -70 °F

-57 °C |

200 °F

93 °C |

212 °F

100 °C |

| H5L16 | Fluoroelastomer (90 Duro FKM)

FKM lip material offers outstanding resistance to high heat. Excellent resistance to oil, gasoline, petroleum hydraulic fluids and hydrocarbon solvents. Very good impermeability to gases and vapours. Very good resistance to flame, weather, oxygen, ozone and sunlight. Very little resistance to oxygenated solvents. Poor tear resistance. |

Good | -40 °F

-40 °C |

325 °F

163 °C |

400 °F

204 °C |

| H5L89 | Fluoroelastomer (90 Duro FKM)

Improved steam resistance. |

Good | -40 °F

-40 °C |

325 °F

163 °C |

400 °F

204 °C |

| N/P | PTFE bonded to NBR lip — PTFE layer provides improved dry running capability, chemical resistance, and reduces torque consumption. | Very Good | -20 °F

-29 °C |

212 °F

100 °C |

250 °F

121 °C |

| F/P | PTFE bonded to FKM lip | Very Good | -40 °F

-40 °C |

325 °F

163 °C |

400 °F

204 °C |

| H1L21 | Ethylene Propylene (75 Duro EPDM)

Excellent heat, ozone and sunlight resistance. Very good low temperature flexibility, good resistance to alkalis, acids (such as acetic) and oxygenated solvents (such as MEK). Provides improved resistance to water and steam in applications where NBR and FKM exhibit poor service life. Good replacement for FKM where solvents are a problem. Not recommended for petroleum oil. |

Very Good | -60 °F

-51 °C |

250 °F

121 °C |

300 °F

149 °C |