Home >> Blog >> Curb Fluid Loss with Braided Packing

Curb Fluid Loss with Braided Packing

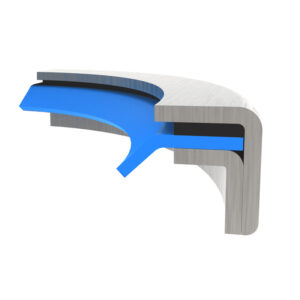

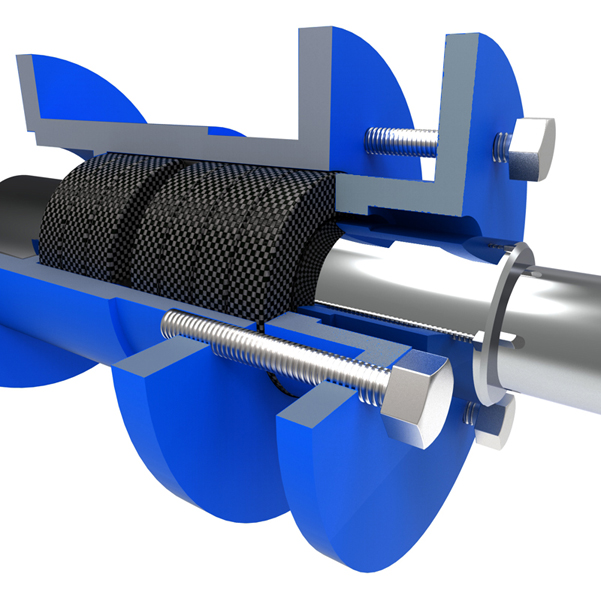

Braided Packing is used as a seal to restrain leakage around rods, shafts, or valve stems and other working parts in machinery requiring the containment of fluids or gases. It is a rope usually woven from relatively soft, flexible materials, the rope is then cut into segments and formed into rings which are placed in the circular space (packing box) between the rotating or reciprocating member and the body of the pump or valve. Once installed, the compression force generated by the tightening of the packing gland produces radial pressure, expanding the rings radially against the side of the packing box and also the reciprocating or rotating member, effecting a seal. Braided packing’s gland tolerances can be more flexible compared to vee packing.

The Right Method of Installing the Braided Packing

Often packing failures are caused by packing being incorrectly installed. The following steps will explain the right way to install packing on pumps to ensure optimal performance:

-

- Remove all the old packing from the packing box: The box and shaft must be cleaned up, and the shaft and sleeves should be checked for wear or scoring. Replace shaft or sleeve if they are extremely worn.

-

- Select the right cross-section of packing or die-forming rings: To determine the correct packing size, measure the diameter of the shaft (inside the packing box area if possible) and then measure the diameter of the packing box (to find the O.D. of the ring). Subtract the I.D. measurement from the O.D. measurement and divide it by two. The result is the needed size.

- Always cut the packing into separate rings if using a coil or spiral packing: Never turn a coil of packing into a packing box. Depending on the construction, rings can be cut with the butt (square), bias or diagonal joints. The most reliable way to cut packing rings is to cut them on a mandrel with a diameter equal to the shaft in the packing box area. If the shaft is not worn, rings can be cut on the shaft outside the packing box. Clasp the packing on the mandrel, but do not stretch a lot. Cut the ring and insert it into the packing box, ascertaining it fits the packing space correctly. All the additional rings can be cut identically, or use the first ring as a master from which the remaining rings are cut. Make sure to cut the rings to the right size. or else the service life is decreased. This is where die-cut rings are advantageous. They provide you with the exact ring size for the I.D. of the shaft and the O.D. of the packing box. There is no loss due to wrongly cut rings.

-

- Install only one ring at a time: Ascertain it is clean of dirt. If desired, lubricate the shaft inside of the packing box. Place rings securely (excluding PTFE filament and Graphite yarn packing, which must be placed very lightly, then tightened slowly after the pump is on stream). Joints of succeeding rings must be staggered and kept at least 90° apart. Every ring must be firmly placed with a tamping tool. When sufficient rings are individually placed so the nose of the gland reaches them, individual tamping must be supplemented by the gland.

-

- Once the final ring is installed, take up bolts finger tight or slightly snugged up. Do not jam the packing into place by a bit much gland loading. Turn on the pump, and take up bolts until leakage is reduced to a bearable minimum. Ascertain gland bolts are taken up equally. Stopping the leakage completely at this point will result in the packing to burn up.

-

- When dealing with a newly packed pump, permit the packing to leak freely: Immoderate leakage during the first hour of operation will allow for a superior packing job over an extended period. Take up slowly on the gland as the packing seats, until leakage is lessened to a bearable level. Never attempt to halt leakage fully, unless it is indicated safe to do so.

-

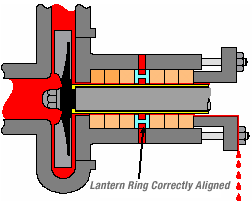

- Give methods of lubricating the shaft & packing for the lantern ring by providing water, oil, grease or liquid handled within the pump. Fittings for this purpose are standard on many pumps (check pump manufacturer’s manual).

-

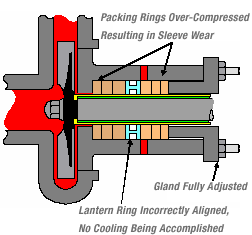

- If the packing box has a lantern ring, check if the lantern ring is slightly behind the fluid inlet in order to allow it to move under the inlet as follower pressure is applied.

-

- Change packing when leakage cannot be withheld by further take-up on the follower gland.

-

- On centrifugal pumps, rotary pumps, and reciprocating pumps, about 80% of damage is on the exterior two packing rings closest to the gland. However, every auxiliary ring does throttle some fluid pressure. It is important to have sufficient rings on the machines so if one fails, another does the sealing, and the machine doesn’t require to be shut down.

Why Packing Fails?

Applications

Braided packing is widely used in the process industries such as steel & paper mills, petrochemical, and in the service industries like marine, utilities, water, sewage, food and nuclear. All kinds of fluids including water, steam, gases, caustics, solutions, acids, oil, gasoline, and various other chemicals over a wide range of temperatures and pressure conditions can be sealed using braided packing.

They are also utilized in centrifugal, rotary, and reciprocating pumps, valves, expansion joints, soot blowers, and lots of other types of machinery. As discussed above braided packing is comparably easy to install and maintain. With proper care, a high degree of successful operation can be expected.

Effective sealing with braided packing is a function of some important associated factors:

- Picking the packing material carefully, which meets the particular application requirements.

- A full assessment of factors like surface speeds, pressures, temperatures, and medium handled.

- Proper regard to appropriate installation and break-in methods.

- Proper measures for equipment maintenance.

To learn about selecting the correct products for your operating environment please contact your local Daemar Technical Sales Representative.