Home >> Slide >> Fiber-Lube Bushings >> Ultracomp Series >> Design Considerations

Design Considerations

Load

All Ultracomp products have very high compressive strength and can carry a sustained static load of over 50,000 psi. However, it is important to remember that dynamic loads must consider compressive yield factors to determine the maximum operating potential. Please contact Daemar for design assistance.

All Ultracomp products have very high compressive strength and can carry a sustained static load of over 50,000 psi. However, it is important to remember that dynamic loads must consider compressive yield factors to determine the maximum operating potential. Please contact Daemar for design assistance.

Lubrication

While Ultracomp is classified as a self lubricating material the use of lubrication will, in most cases, enhance the long term performance of the bearings. Friction is reduced and thus heat buildup so wear life is extended. In high load, oscillating applications the lubricating additives in the Ultracomp are drawn to the surface and maintain a continuous source of low friction lubrication film. The use of heavy greases can cause debris to become trapped and result in a lapping effect on the bearing. Daemar recommends a light weight oil or grease if your application requires any lubrication.

While Ultracomp is classified as a self lubricating material the use of lubrication will, in most cases, enhance the long term performance of the bearings. Friction is reduced and thus heat buildup so wear life is extended. In high load, oscillating applications the lubricating additives in the Ultracomp are drawn to the surface and maintain a continuous source of low friction lubrication film. The use of heavy greases can cause debris to become trapped and result in a lapping effect on the bearing. Daemar recommends a light weight oil or grease if your application requires any lubrication.

Friction

Coefficient of friction is directly affected by load and speed of the application. As a rule, the coefficient of friction values of Ultracomp are between 0.08 and 0.15. The higher the working load, the lower the friction values will be. Stick slip is virtually eliminated after break in of the bearing and ongoing static and dynamic friction will be consistent from that point on. For more specific frictional values contact Daemar.

Coefficient of friction is directly affected by load and speed of the application. As a rule, the coefficient of friction values of Ultracomp are between 0.08 and 0.15. The higher the working load, the lower the friction values will be. Stick slip is virtually eliminated after break in of the bearing and ongoing static and dynamic friction will be consistent from that point on. For more specific frictional values contact Daemar.

Mating Surfaces

For optimum wear and friction performance, Daemar recommends a 12-16rms surface finish on the dynamic mating surface. The static surface of the hardware should be 32 rms for improved bearing retention. Minimum hardness of the dynamic mating component should be 45RC or harder. We recommend against chrome plate as it can increase wear of the bearing. ENP, Plasma and other hard coat processes are desirable. Stainless steel can be used with Ultracomp products in certain conditions but we recommend you call Daemar to review the particulars of your application.

For optimum wear and friction performance, Daemar recommends a 12-16rms surface finish on the dynamic mating surface. The static surface of the hardware should be 32 rms for improved bearing retention. Minimum hardness of the dynamic mating component should be 45RC or harder. We recommend against chrome plate as it can increase wear of the bearing. ENP, Plasma and other hard coat processes are desirable. Stainless steel can be used with Ultracomp products in certain conditions but we recommend you call Daemar to review the particulars of your application.

Installation of Ultracomp Bearings

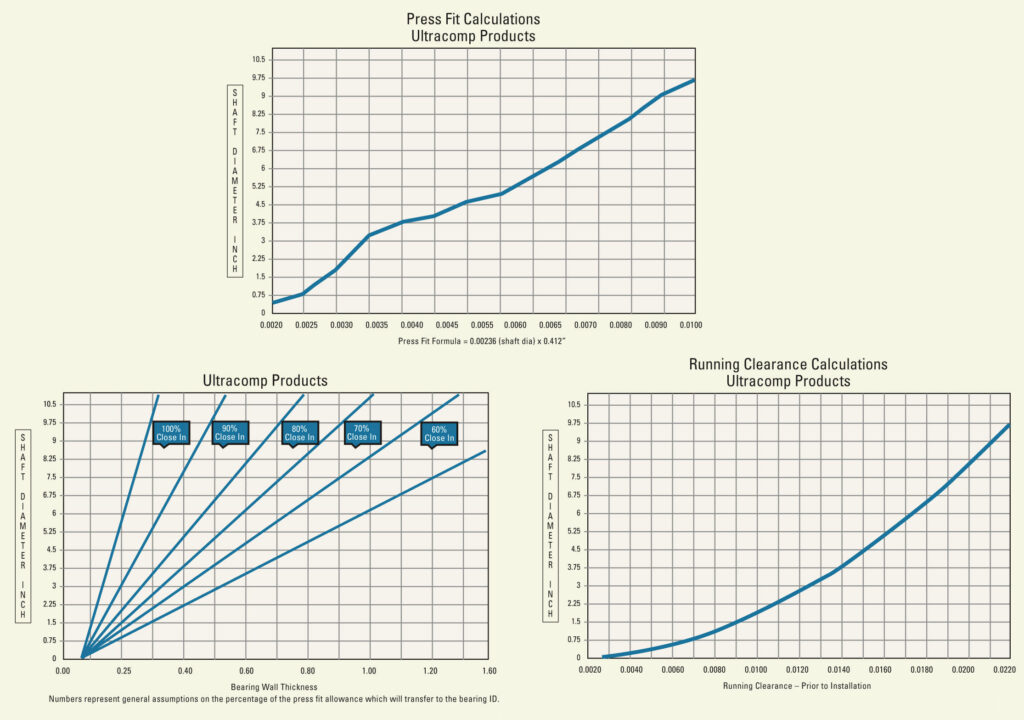

There are several factors to take into consideration for the proper fit of Ultracomp bearing materials is dependent upon close adherence to these design factors. Please refer to Charts 1 thru 3 on page 6 for Press Fit, Close In and Running Clearance data. Ultracomp bearings can be freeze fitted or adhesively bonded in certain applications. Contact Daemar for any questions regarding fit and finish.

There are several factors to take into consideration for the proper fit of Ultracomp bearing materials is dependent upon close adherence to these design factors. Please refer to Charts 1 thru 3 on page 6 for Press Fit, Close In and Running Clearance data. Ultracomp bearings can be freeze fitted or adhesively bonded in certain applications. Contact Daemar for any questions regarding fit and finish.

Speed

In most cases, the maximum sustained speed for Ultracomp is 15 sfpm. Since Ultracomp is a insulative material, frictional heat generation does not allow for high rotational speeds. In lubrication, speeds can be dramatically higher. Due to the heat transfer properties of the fluid. Water is an excellent lubricating media for Ultracomp as are all greases and oils. Daemar has other options available for higher speed applications so please consult our Technical Team for further assistance.

In most cases, the maximum sustained speed for Ultracomp is 15 sfpm. Since Ultracomp is a insulative material, frictional heat generation does not allow for high rotational speeds. In lubrication, speeds can be dramatically higher. Due to the heat transfer properties of the fluid. Water is an excellent lubricating media for Ultracomp as are all greases and oils. Daemar has other options available for higher speed applications so please consult our Technical Team for further assistance.

Chemical Resistance

Ultracomp products are resistant to most chemicals including acids and bases. Active solvents, however, can be a problem. Ultracomp is UV stable and is recommended for long term outdoor use.

Ultracomp products are resistant to most chemicals including acids and bases. Active solvents, however, can be a problem. Ultracomp is UV stable and is recommended for long term outdoor use.

Electrical and Magnetic

Ultracomp products are excellent dielectric materials and can be used in power switchgears, dielectric standoffs, thrust rings and similar gear. Ultracomp is nonmagnetic and will not sustain a static charge.

Insulation Resistance – 2,000 MegaOhms

Dielectric Strength – 210 V/mil.

Thermal Expansion

Since Ultracomp products are insulative by nature, it is very important to consider thermal expansion values during the design process. Press fits and running clearances can be affected dramatically by thermal cycling and, when combined with frictional heat, can be the difference between success or failure of the bearing.

Since Ultracomp products are insulative by nature, it is very important to consider thermal expansion values during the design process. Press fits and running clearances can be affected dramatically by thermal cycling and, when combined with frictional heat, can be the difference between success or failure of the bearing.