Home >> Blog >> Self-Lubricating Bearings vs Standard Bearings: When to Make the Switch

Self-Lubricating Bearings vs Standard Bearings: When to Make the Switch

Bearings rarely get much attention until something goes wrong. A sudden failure, unexpected downtime, or constant maintenance can quickly turn a small component into a big operational problem. One of the most common questions engineers and maintenance teams ask is simple. Should we continue with standard bearings, or is it time to move to self-lubricating bearings?

At Daemar, we help customers make bearing decisions that improve uptime, reduce maintenance, and support long-term performance. This guide breaks down the real differences between standard and self-lubricating bearings, and how to know when making the switch makes sense.

At Daemar, we help customers make bearing decisions that improve uptime, reduce maintenance, and support long-term performance. This guide breaks down the real differences between standard and self-lubricating bearings, and how to know when making the switch makes sense.

Understanding the Difference

Standard Bearings

Standard bearings rely on external lubrication, usually grease or oil, to reduce friction and wear. In many applications, they perform well, but only when lubrication is applied correctly and consistently.

Over time, teams often run into issues such as frequent relubrication, grease washout in wet environments, inconsistent performance, and higher risk of contamination in sensitive applications.

Self-Lubricating Bearings

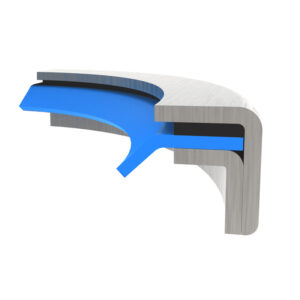

Self-lubricating bearings are designed with solid lubricants built directly into the bearing material. As the bearing operates, lubrication is released gradually, keeping friction low without the need for manual greasing.

This results in cleaner operation, more consistent performance, and far less maintenance over the life of the bearing.

Key Differences at a Glance

|

Feature

|

Standard Bearings

|

Self-Lubricating Bearings

|

| Lubrication method | Manual | Built-in solid lubricant |

| Maintenance needs | High | Low |

| Downtime risk | Moderate to high | Significantly reduced |

| Clean operation | Limited | Excellent |

| Washdown resistance | Inconsistent | Reliable |

| Long-term cost | Higher over time | Lower total cost |

When Does It Make Sense to Switch?

- Maintenance Is Becoming a Burden

If your team is spending too much time on lubrication schedules or replacing bearings earlier than expected, self-lubricating bearings can free up both labor and resources. - Wet or Washdown Environments

In food processing, beverage lines, and packaging equipment, frequent washdowns can strip grease from standard bearings. Self-lubricating bearings continue to perform even when exposed to moisture and cleaning chemicals. - Contamination Is a Real Concern

Grease leaks can create safety and quality issues in regulated industries. Self-lubricating bearings help maintain cleaner equipment and support compliance with hygiene and safety standards. - Bearings Are Hard to Access

When bearings are installed in enclosed or elevated equipment, routine lubrication becomes difficult and risky. Eliminating the need for relubrication improves safety and reduces downtime. - Operating Conditions Are Demanding

Applications involving high loads, continuous operation, or temperature extremes often push standard bearings beyond their limits. Self-lubricating options are better suited for these challenging conditions.

Most Used In

- Food and beverage processing

- Packaging and automation

- Pharmaceutical manufacturing

- Material handling and conveyors

- Industrial machinery

Are Self-Lubricating Bearings the Right Long-Term Choice?

While self-lubricating bearings may come with a higher upfront cost, they often deliver a lower total cost of ownership through reduced downtime, minimal maintenance, longer service life, and more reliable performance. With Daemar’s wide range of self-lubricating bearing solutions, engineers and maintenance teams can confidently select the right bearing based on load, environment, compliance requirements, and lifecycle cost. Making the switch is not just a maintenance upgrade, it is a strategic move toward cleaner operations, improved reliability, and predictable performance when lubrication challenges begin to impact your operation.

Explore Daemar’s full Slide Components lineup here.