Home >> Seal >> Trelleborg Sealing Solution >> Trelleborg Aircraft Seals & Aerospace Seals >> AIRFRAME SEALS AND OTHER SPECIAL AIRCRAFT SEALS

AIRFRAME SEALS AND OTHER SPECIAL AIRCRAFT SEALS

Download Trelleborg’s Aerospace Sealing Systems Product Catalogue & Engineering Guide.

Download Trelleborg’s Product Range Aerospace sealing solutions Catalogue

Download Trelleborg’s Airseal Catalogue

Airframe Seals | Trelleborg Sealing Solutions

Airframe Seals | Trelleborg Sealing Solutions

This is a broad family of products, individually developed and manufactured for unique applications. In general, these seals are static and offer low friction and good abrasion resistance characteristics. They are typically used for the aerodynamic sealing of doors, windows, ailerons, spoilers, canopies, hatches and panels. Airframe seals are typically bonded into place and can be made conductive. They can also be strategically reinforced, to offer the load and deformation properties required for variable working conditions. An FEA (Finite Element Analysis) service is available to assist in design of this seal type.

Features: Static

| Ø – Range | Pressure Range | Temp. range | Velocity |

|---|---|---|---|

| – | – | – | – |

| – | – | – | – |

–

Bonded Seals | Special Aircraft Seals | Trelleborg

Bonded Seals | Special Aircraft Seals | Trelleborg

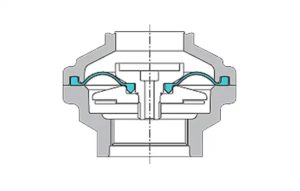

The Bonded Seal comprises a metal annulus, square or rectangular in section, to which an elastomeric ring of trapezoidal section is bonded. Developed to replace copper type washers in high-pressure hydraulic and pneumatic threaded connections, the metal ring resists the pressure bursting forces and limits the deformation of the elastomeric element. This prevents over-compression and extrusion.The standard type Bonded Seal is supplemented by a range of self-centering Bonded Seals that eliminate the possibility of leakage, by ensuring it is properly centered during assembly. Available in a wide range of aerospace and defense released materials. Custom designs are also available.

Features: Static

| Ø – Range | Pressure Range | Temp. range | Velocity |

|---|---|---|---|

| M2.5 – M125 mm | 100 MPa | -30°C +200°C | — |

| 1/8 – 2 1/2 in | 14500 psi | -20°F +390°F | — |

Custom Mouldings and Extrusions | Aircraft Seals | Trelleborg

Custom Mouldings and Extrusions | Aircraft Seals | Trelleborg

A wide range of custom molded and extruded products can be made in a variety of elastomeric and thermoplastic materials. Components for all areas of Aerospace applications can be offered with the assistance of the Trelleborg Sealing Solutions design department. Alternatively, products can be manufactured to customer drawings. Typical components include environmental bellows, facemasks, protective covers, bonded plates, inflatable seals, extrusions and assemblies combining rubber, metal and plastic parts.

Features: Static

| Ø – Range | Pressure Range | Temp. range | Velocity |

|---|---|---|---|

| – | – | – | – |

| – | – | – | – |

Diaphragms | Special Aircraft Seals | Trelleborg

Diaphragms | Special Aircraft Seals | Trelleborg

All diaphragms are custom designed to suit the requirements of an application and can either be manufactured from fabric-reinforced or thin membrane rubber-only material. Higher pressures can be accommodated, by increasing the burst resistance, with synthetic fabric reinforcement. This also gives the advantages of extended product life, reduced deformation and allows the use of thinner sections to improve sensitivity of control. Diaphragms are commonly used in aircraft fuel systems, for example in control and metering valves.

Features: Static

| Ø – Range | Pressure Range | Temp. range | Velocity |

|---|---|---|---|

| — | 0.05-10 MPa | -50°C +325°C | — |

| — | 7-1,450 psi | -55°F +615°F | — |

Environmental Seals | Special Aircraft Seals | Trelleborg

The Bonded Seal comprises a metal annulus, square or rectangular in section, to which an elastomeric ring of trapezoidal section is bonded. Developed to replace copper type washers in high-pressure hydraulic and pneumatic threaded connections, the metal ring resists the pressure bursting forces and limits the deformation of the elastomeric element. This prevents over-compression and extrusion.The standard type Bonded Seal is supplemented by a range of self-centering Bonded Seals that eliminate the possibility of leakage, by ensuring it is properly centered during assembly. Available in a wide range of aerospace and defense released materials. Custom designs are also available.

Features: Static

| Ø – Range | Pressure Range | Temp. range | Velocity |

|---|---|---|---|

| – | – | – | – |

| – | – | – | – |

Fire Seals | Special Aircraft Seals | Trelleborg

Fire Seals | Special Aircraft Seals | Trelleborg

These are dual-purpose components, acting as pressure seals, as well as being barriers for fire containment. Fire seals are elastomeric, with glass or ceramic reinforcement. They are commonly tested to ISO 2685, which dictates that the seals withstand an applied flame of 1100°C for 15 minutes, without failure. Fire seals can also be made in conductive variants for RFI screening.

Features: Static

| Ø – Range | Pressure Range | Temp. range | Velocity |

|---|---|---|---|

| – | – | – | – |

| – | – | – | – |

Grease Seal | Special Aircraft Seals | Trelleborg

Grease Seal | Special Aircraft Seals | Trelleborg

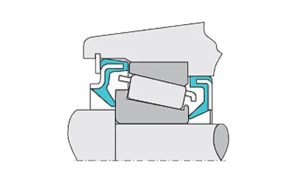

Grease Seals are bespoke products used to protect and prolong the service life of aircraft wheel bearings. They are usually custom designed rubber rotary lip seals, designed to restrict bearing grease loss and prevent water and dirt ingress, during normal service and cleaning conditions. Snap-fitting Polytetrafluoroethylene (PTFE) variants are also available. Grease Seals can be located in a number of ways either designed to: incorporate retention features, press-fit into the wheel hub or axially locate with circlips or sleeves. They have been designed and tested to include 1 mm variances in axial bearing face location. Grease Seal types are offered for both inboard and outboard-of-bearing positions. They can also be designed specifically to aid their assembly as original equipment or insubsequent retrofitting.

Features: Static

| Ø – Range | Pressure Range | Temp. range | Velocity |

|---|---|---|---|

| – | – | – | – |

| – | – | – | – |

Inflatable Seals , Aerospace Seals, Airframe Seals | Trelleborg

Inflatable Seals , Aerospace Seals, Airframe Seals | Trelleborg

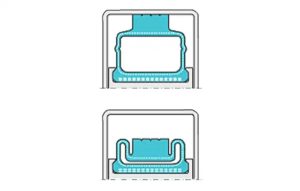

Inflatable seals are individually designed and manufactured to satisfy exacting customer specifications, with applications including canopy seals for military aircraft. The seals are either bonded in position or designed to be mechanically restrained by the use of retaining plates. Inflatable seals normally include fabric reinforcement and can also be made conductive. An FEA (Finite Element Analysis) service is available to assist in design of this seal type.

Features: Static

| Ø – Range | Pressure Range | Temp. range | Velocity |

|---|---|---|---|

| – | – | – | – |

| – | – | – | – |