Home >> Caplugs by Product Type >> Caplugs by Material

Select By Material

Aluminum

Offered by Caplugs as a cap or plug for use in the Aerospace, Automotive and Fluid Power industries or as an extruded channel for the Converting industry.

Flex500

Flex500® was developed as an economical alternative to silicone for the Masking industry. While silicone offers extreme durability and resilience, their cost requires you to clean and reuse the parts to justify the expense – this can be labor-intensive, costly and risks future contamination. Flex500® is 1/3 the cost of silicone, making it ideal for one-time use in a high temperature finishing process.

Paper

Our “Environmentally friendly” natural paper is formulated from a blend of 90% virgin pulp and 10% post-consumer recycled paper. It is 100% recyclable. Closures made from this material will withstand intermittent temperatures up to 400° F (204° C) making it ideal for high-temperature applications which may degrade typical plastic caps and plugs.

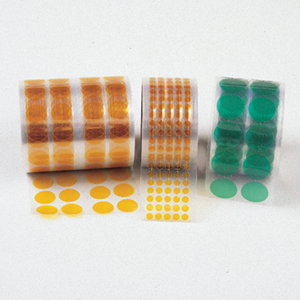

PETG

Our “Environmentally friendly” natural paper is formulated from a blend of 90% virgin pulp and 10% post-consumer recycled paper. It is 100% recyclable. Closures made from this material will withstand intermittent temperatures up to 400° F (204° C) making it ideal for high-temperature applications which may degrade typical plastic caps and plugs.

Nylon

Polyamides “Nylon” are one of the most widely used technical thermoplastics. They offer an excellent combination of mechanical performance and cost. There are many grades of Polyamides available today, the most common being PA6 (Nylon 6) and PA66 (Nylon 6/6).

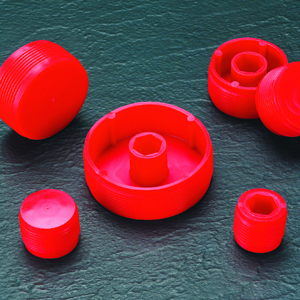

Polypropylene

A high strength, rigid plastic which has high resistance to chemicals and has excellent machine qualities. Resistant to intermittent temperatures up to 250° F.Available in 3 standard colors: Red, Black, Natural/Translucent (color dependent upon specific product series).

Silicone Rubber

Silicone rubber is an inorganic synthetic elastomer. Made from a cross-linked silicone based polymer that is reinforced with filler, it offers a combination of properties that make it the ideal choice for many applications. Silicone Rubber provides longer service life in adverse environments and a wider operating temperature range from -148ºF to 600ºF (-100ºC to 316ºC).

Vinyl

Polyvinyl chloride (PVC) more commonly referred to as Vinyl, is now the world’s second most used plastic and it is one of the most valuable products of the chemical industry. Vinyl’s properties can enhanced by compounding it with additives or modifiers to meet the needs of the application. Caplugs engineers have the experience to help determine the best material for your application.