Home >> Blog >> High-Pressure Rotary Shaft Seals

High-Pressure Rotary Shaft Seals

Generally, shaft seals are designed for pressure-free applications. But there are several applications in which machinery operates under high pressures. When high pressure is combined with the rotating motion of the shaft, it puts the rotary seals to the test. They must withstand pressure loads like those in hydraulic cylinders. Moreover, under high pressure, there is more friction between the seal lip and shaft, heat, and wear of the seal lip, which can cause premature or catastrophic seal failure in a very short period. High-Pressure Rotary Shaft Seals should be used for effective and efficient sealing performance to overcome this challenge. These seals feature optimized geometries and design, which help them to perform well under high pressure. Our High-Pressure Rotary Shaft Seals support applications with pressure as high as 25 bar, and their design offer the following features:

- Lower parasitic friction

- Lower heat build-up

- Lower seal and shaft wear

- Lower torque generation

- Lower required power generation

Working

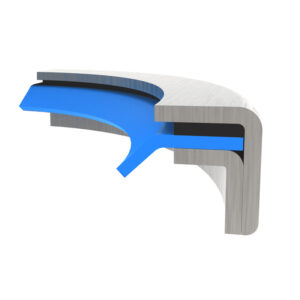

High-Pressure Rotary seals that are used for high-pressure applications have a solid cross-section, are developed to seal a pressurized lubricant, and possess hydrodynamic waves that encounter the pressurized lubricant. These fluid waves pump lubricant into the engaged sealing interface when the shaft spins. This results in reduced friction, wear, and seal-generated heat. The decreased seal temperature indicates better retention of material properties, including high-pressure extrusion resistance.

In applications where the fluid used is not a lubricant, the rotary seal is paired with an oppositely facing seal, and lubricant is added between them that must pressurize to a value equal to or greater than the pressure of the process fluid. This results in one rotary seal creating a partition between the process fluid and the seal lubricant and the other one retaining the lubricant pressure. Both rotary seals are installed in housing grooves and compressed radially against the spinnable shaft.

Any high-pressure rotary seal aims to control fluid loss through the clearance space, which is there between an equipment housing and a shaft. The less the clearance space and the less it changes due to factors like shaft runout and deflection and housing pressure breathing, the better the seal can resist high varying pressure — given the shaft doesn’t rub against the housing and generate sufficient heat to deteriorate the seal.

Factors Affecting Sealing

- Seal carrier’s type

- The clearance opening size

- Material of the seal

- Shaft rotary speed

- Hydrodynamic wave’s belligerence

- Application temperature

- The amount of heat transfer

Medium & High-Pressure Rotary Shaft Seals

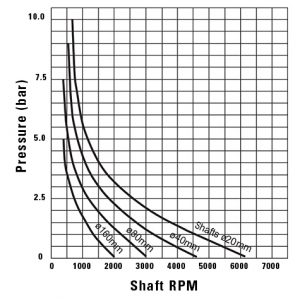

Controlling the leakage of medium to high pressure on a machine with rotary motion is one of the most difficult sealing applications. Daemar offers four different profiles of medium and high-pressure rotary shaft seals, each suitable for different pressure ranges. Each seal is designed to meet needs of specific application requirements. These medium and high-pressure seals are available in a range of O.D. sizes. The design can accommodate surface speeds up to 45 m/s (147.6 ft/s) and temperatures ranging from -90°C to 250°C (130°F to 482°F).

Profiles

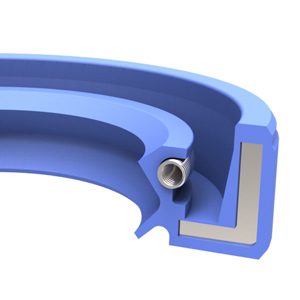

BABSL Premium Medium-Pressure Double-Lip Oil Seal

This seal also features an integrated steel reinforcement element with the dynamic seal lip constructed with NBR 72 Shore A, also available in FKM and HNBR. The OD of the seal is covered with rubber that creates a tight seal with the housing bore. The secondary lip helps in effectively protecting against airside contaminants and also, serves as a lube retainer. Pressure resistant style for use without back-up ring, a retaining device must be used to hold the seal in place when the application pressure is above recommended psi.

Size Range (O.D.): 5.00mm to 1600mm

Pressure: up to 10 bar (depending on other operating conditions)

Surface Speed: Up to 5 m/s

Material: NBR 72 Shore A, also available in FKM and HNBR

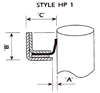

Style HP1

Size Range (O.D.): 30mm to 530mm

Pressure: up to 5 bar

Vacuum: 0.1 torr.

Dimensions: A= 0.5mm B=6mm C=7mm

Metal Parts: Stainless steel

Sealing Elements: Black or White PTFE

Captive Elastomer: Viton (up to 250°C)

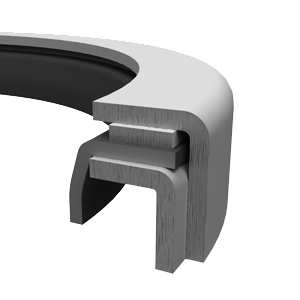

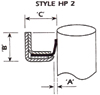

Style HP2

Size Range (O.D.): 30mm to 530mm

Pressure: up to 10 bar

Vacuum: 0.1 torr.

Dimensions: A= 0.25mm B=6mm C=7mm

Metal Parts: Stainless steel

Sealing Elements: Black or White PTFE

Captive Elastomer: Viton (up to 250°C)

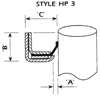

Style HP3

Size Range (O.D.): 46mm to 530mm

Pressure: up to 25 bar

Vacuum: 0.1 torr.

Dimensions: A= 1.5mm B=6mm C=8mm

Metal Parts: Stainless steel

Sealing Elements: Black or White PTFE

Captive Elastomer: Viton (up to 250°C)

Medium Pressure Applications

Pressure: up to 5 bar

Typical Applications

– One-sided pressure sealing

– Sealing in pressurized environments without additional backup rings, for example: rotational pressure sealing in hydraulic pumps, hydraulic motors, hydrodynamic couplings. It is also used in compressors, dispensing heads, machine tools, brakes, clutches, mixers, etc. Particularly suitable for sealing low viscosity and gaseous media.

*Each application has different needs and requires a profile that meets application needs.

High-Pressure Applications

Pressure: up to 10 bar

Typical Applications

– Lesser torque and power consumption, sealing one-sided varying pressure.

– It is also used in equipment like Pumps, motors, rotary couplings, rotary manifolds, slew rings, positioning equipment, compressors, machine tools, brakes, clutches, winches and draw-works, mixers, drilling equipment, downhole tools, swivels, and others.

*Each application has different needs and requires a profile that meets application needs.

Custom Seal Dimensions for your specific application

If your unique application requires custom seals that must meet your application needs, Daemar can supply high-pressure rotary seal profiles with custom dimensions to support your application needs. Fill out our online Seal Design Sheet form with your requirements, and we can try and quote according to your request. Daemar can also manufacture custom seals in short lead times to meet your urgent needs and be your reliable supplier.