Home >> Blog >> Versatile V-Rings for Shaft Seal Applications

Versatile V-Rings for Shaft Seal Applications

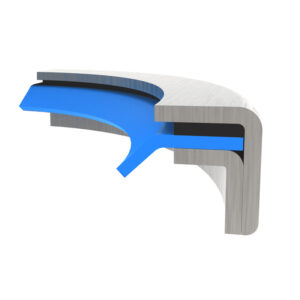

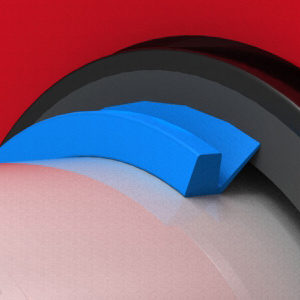

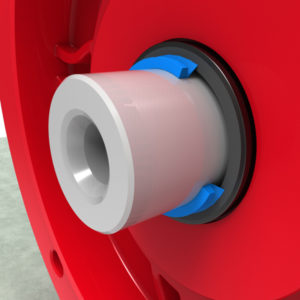

A V-Ring is a solid axial shaft seal that uses centrifugal slinger action to prevent dirt, moisture, and other unwanted contaminants from entering an oil seal or the housing while simultaneously keeping lubricants inside. The V-Ring rotates with the shaft and holds itself in position by its flexible fit on the shaft. Sealing is induced by the contact between the seal lip and the counterface. V-rings work well on their own but are mostly used in combination with other seals like radial shaft seals, and sometimes they are also used as pre-sealing material for bearings.

Advantages of V-Rings

V-Rings are very versatile and offer many advantages.

- They help in reducing the wear and extending the service life of oil seals, shafts, and bearings.

- Since they are made of rubber and have an elastic nature, they can be easily stretched over flanges or other components for easy installation with minimal machine disassembly. Just ascertain the shaft is clean and dry, administer a bit of lubricant to the V-ring lip and slide the v-ring down until the elastic lip touches the counterface. The lip presses against the counterface with minute pressure and friction.

- V-rings offer very little torque drag and heat built up and do not require costly countersurface preparation.

- Functions nicely in dry applications, on spinning shafts and oscillating shafts, and at high velocities above 3000 FPM.

- Wide tolerations permit a single v-ring to fit numerous shaft sizes and to solve significant shaft misalignment and eccentricity in the shaft. Its durability assures a prolonged work life and that it won’t be damaged while installation.

DMR V-Ring Profiles & Their Applications

V-rings are very versatile for pressure-less application usage and are mostly used in rolling mills, farm machinery and electric motors. Daemar offers V-Rings in 4 profiles (VA, VS, VL and VE) and two materials; Buna ‘N’ and Viton. V-Rings constructed of NBR (temperature range: – 40 to + 100°C) and FKM (temperature range: – 20 to + 200°C) exhibit good chemical resistance to numerous greases and mineral oils.

VA V-Rings

Standard style, VA seal has a straight back for shaft from 3 mm to 2000 mm.

Typical applications: Ideal for conveyor rollers and appliances.

Competitor types: VR1

VS V-Rings

Widebody (angled back) for higher speed applications.

Typical applications: Commonly used in automotive and agricultural applications.

Competitor types: VR2

VL V-Rings

Narrow cross-section where space is limited.

Typical applications: used in pillow block applications.

Competitor types: VR3

VE V-Rings

Heavy-duty design for large diameter applications (longer lip can accommodate greater shaft misalignment).

Typical applications: Commonly used in rolling mills as a dirt/water excluder seal.

Competitor types: VR4

Contact your local Daemar Technical Sales Representative for more information on V-Rings