Home >> Seal >> Trelleborg Sealing Solution >> Hydraulic Wear Rings

Hydraulic Wear Rings

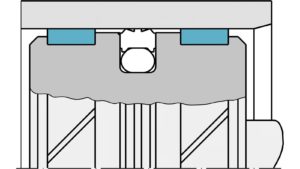

HiMod® Slydring® | Hydraulic Wear Rings | Trelleborg

HiMod® Slydring® | Hydraulic Wear Rings | Trelleborg

Features: Helix, Oscillating and Reciprocating

| Ø – Range | Pressure Range | Temp. range | Velocity |

|---|---|---|---|

| 8 – 915 mm | 50 MPa | -40°C +135°C | 1 m/s |

| 0.315 – 36 in | 7200 psi | -40°F +275°F | 3 ft/s |

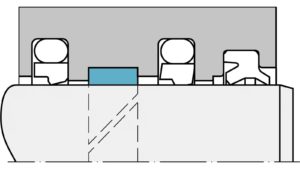

Orkot® Slydring® | Hydraulic Wear Rings | Trelleborg

Orkot® Slydring® | Hydraulic Wear Rings | Trelleborg

Features: Helix, Oscillating and Reciprocating

| Ø – Range | Pressure Range | Temp. range | Velocity |

|---|---|---|---|

| 8 – 1,500 mm | 100 MPa | -40°C +120°C | 1 m/s |

| 0.315 – 59 in | 14,500 psi | -40°F +250°F | 3 ft/s |

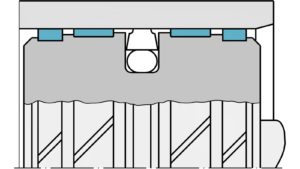

Turcite® Slydring® | Hydraulic Wear Rings | Trelleborg

Turcite® Slydring® | Hydraulic Wear Rings | Trelleborg

Features: Helix, Oscillating and Reciprocating

| Ø – Range | Pressure Range | Temp. range | Velocity |

|---|---|---|---|

| 8 – 4,200 mm | 15 MPa | -60°C +200°C | 15 m/s |

| 0.315 – 165 in | 2200 psi | -75°F +390°F | 50 ft/s |