EN | FR | ES

Home >> Shaft Seals >> DMR Bearing Isolators >> LW Series Bearing Isolator

LW Series - Bearing Isolator

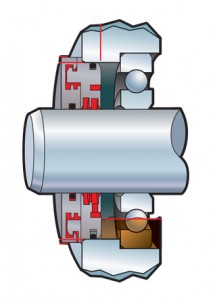

LW – Enhanced standard isolator with wraparound mount

Wrap-around non-contact, labyrinth design with enhanced geometry provides unsurpassed bearing protection for rotary equipment. Constructed of proprietary PTFE, retains heavy oil splash and excludes aggressive contaminants in non-flooded applications.

Technical Specifications

- OPERATION TYPE: Non-Flooded

- MAXIMUM SURFACE SPEED: Up to 5,000 fpm (25 m/s)

- PRESSURE RATING: 0 psi

- AXIAL MOVEMENT: 0.020 inch (0.51 mm)

- ECCENTRICITY: 0.020 inch (0.51 mm)

- OPERATING TEMPERATURE: -40° to 250 °F / -40° to 121 °C

- SHAFT DIAMETER: 0.492 to 10.000 inch (12.5 to 254 mm)

- BORE DIAMETER: 0.886 to 11.575 inch (22.5 to 294 mm)

- SEAL MATERIAL: PTFE

- O-RING MATERIAL: FKM is standard. Alternates available

Performance Advantages

Machine downtime due to bearing failure is costly. By keeping lubrication in and contaminants out, ProTech™ bearing isolators provide reliable, two-way sealing protection of rotating equipment for extended bearing life. Labyrinth sealing technology applied to high performance materials allows the ProTech LW Profile bearing isolator to operate far beyond the shaft speed limits of standard radial lip seals and avoids shaft wear. Because it is a precision-machined seal, costs can be eliminated on tooling charges, allowing retrofit of most shaft and bore combinations.

The non-contact design has virtually no torque consumption, will not wear or groove shafts, and allows for non-lubricated dry running. It also accommodates the greatest axial movement in the industry, reducing a major factor that causes labyrinth seal failure.

We can custom engineer solutions to meet exacting specifications for either new or retrofit applications. When used to replace seals during planned or unplanned rebuilds, the LW Profile lowers shaft cost due to liberal surface finish specifications.

Design

The LW Profile with its wrap-around geometry and enhanced rotor design features a more robust and aggressive labyrinth profile over standard designs. Enhanced drainback and internal oil splash grooves manage heavy oil splash in the bearing cavity. An external O-ring on the outside diameter of the ProTech stator allows for easy seal installation, maintains a press fit in the seal housing, and provides a static seal against the bore for lubricant retention. The stator has a sophisticated series of grooves to retain oil splash, the most effective design for oil retention when compared to various competitor designs.

The rotor uses an external O-ring to maintain a static press fit on the shaft. Since the rotor spins with the shaft, it will not wear, groove, or damage the shaft. This eliminates costs associated with having to recondition the sealing surface of the shaft.

The rotor and stator are assembled at Parker’s factory where they are permanently unitized, allowing for a one-piece installation. This unitized design also maintains the seal’s integrity by keeping high-pressure water spray, vibration or axial movement from separating or increasing the gap between the rotor and stator.

Applications

The LW profile is an enhanced design for applications with aggressive oil splash and heavy contamination. It is ideal for sealing and protecting the bearing housings of electric motors, pumps, mixers, gear boxes, blowers and custom equipment against heavy water spray and dry contaminants. The flange seats against the housing and acts as an installation guide by ensuring the seal alignment is correct.

The LW design is excellent for retaining grease and oil splash, however the oil level must be below the inboard oil drainback (non-flooded). The LW Profile is recommended over alternate profiles where contamination is heavy, but is not compatible with oil lubricated vertical down systems.

Total Eccentricity: 0.020” (0.51 mm)

Shaft speed: Up to 3,000 fpm (15 m/s). Contact Parker for speeds >3,000 fpm (15 m/s).

Maximum internal pressure: 0 psi (0 bar)

Axial Movement: 0.020” (0.51 mm) Special designs up to 0.070” (1.78 mm)

Shaft/Bore: Tolerances: ±0.002” (±0.0 5mm)

The LW Profile shaft mounting positions and respective compatible lubrication types are:

- Horizontal Mounting: Compatible for grease, oil and dry

- Vertical Up Mounting: Not recommended. Consider LX Profile without drain port.

- Vertical Down: Compatible for grease, and dry. Not compatible for oil.

Materials

Stator & Rotor: ProTech uses proprietary PTFE compounds making it well suited for harsh environments, such as citric acids and strong caustics. This superior chemical resistance allows for the standardization of a single material within a plant, eliminating the cost associated with stocking duplicate sizes in expensive stainless steel or other exotic materials.

Characteristics of the various PTFE materials offered:

- Temperature range: -40 to 250 F (-40 to 121 C)

- Higher temperature applications can be handled with alternate materials.

- Low wear, low coefficient of friction. Superior for dynamic applications.

- FDA compliant

- Anti-microbial

- USDA 3S sanitary standards for food and dairy product contact

O-Rings: Come standard as FKM, but are also available in:

- NBR

- FDA silicone

- Fluorosilicone

- EPDM

- Aflas®

Size Range

The LW Profile is manufactured in standard shaft diameters ranging from 0.492” to 10” (12.5 mm to 254 mm). Because this is a precision machined seal, we can manufacture virtually any configuration.