Home >> Blog >> Align Shafts for Rotating Equipment with Slotted Shim

Align Shafts for Rotating Equipment with Slotted Shim

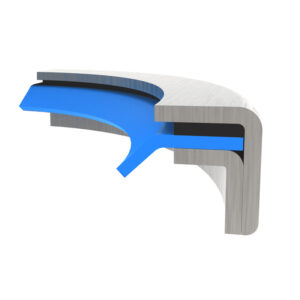

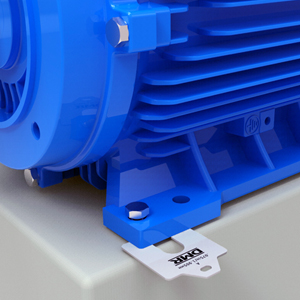

Slotted Shims are used for shaft alignment of rotating equipment. The power source (motor/engine) shaft must be aligned with the mating equipment shaft (pump, compressor, gearbox, etc). Without proper alignment, equipment may experience damaging vibration or excessive shaft and bearing wear, all resulting in a mechanical breakdown. Additionally, for installations where the mounting surface is uneven, slotted shims allow each foot/flange to be independently supported and tightly bolted to the rigid foundation, thus preventing excessive vibration at the mounts.

The convenient slot enables the shim to be inserted, removed, and adjusted without disassembling the machinery and the tabs on the shims allow for easy insertion and removal. Thus, saving your maintenance teams time and ensuring your equipment runs smoothly.

Daemar Slotted Shim Advantages

Daemar slotted shims have the tightest tolerances in the industry. Shims .001″ through .031″ are as tight as the stainless steel industry can supply us. Sizes .050″ through .125″ are made from re-rolled material which reduces thickness tolerances to +/- .002″. Our shims are not only the tightest in the industry they are also the flattest.

Slotted shim is utilized for alignment in many industries and applications including:

- Fans

- Pumps

- Blowers

- Turbines

- Die Stampers

- Compressors

- Punch Presses

- Gearboxes

- Journal Boxes in Steel Mills

- And in machinery in chemical plants, paper mills, power plants, refineries, and HVAC facilities.

Guidelines for Installing Slotted Shims

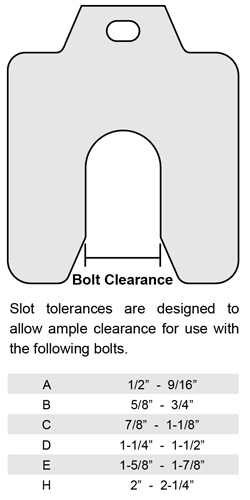

Daemar’s slotted shims come in several sizes – A, B, C, D, E, and H. When selecting the size of shim the first consideration must be the diameter of the bolt. The shim should fit around the bolt with enough clearance to keep the threads from biting into the shim, yet should not have a gap bigger than the washer used on the foot bolt. If the gap is too large, the foot may tend to bend while tightening. (See figure 1)

Shim stacks must be measured with a micrometre or calliper. Never just go solely by the numbers printed on the shim. When measuring shims for replacement, try to remove the entire stack of shims, being careful not to disturb the stack while removing. Measure the entire stack with a micrometer or caliper. The best place to measure is normally in the inside radius of the shim.

Use fewer, thicker shims – not a large number of thinner shims. Try to use no more than 3 or 4 shims under each foot whenever possible. If the machine needs a large amount of shim, try to use one thick steel block, and a small number of shims. The block can be drilled, milled, or torched out, but should be ground flat before use.

When placing shims under machine feet, “sandwich” slimmer shims in between thicker shims whenever feasible.

Ensure the shims are clean and flat. As well, debris such as dirt, rust, paint and sand between the foot and the base will take up space and effect the required shim stack height. Whenever possible clear all debris and use clean stainless steel shims

Shims must be placed under the motor feet until they contact the bolt and then be pulled back slightly. This is so the bolt threads do not bend the shim as bolts are tightened.

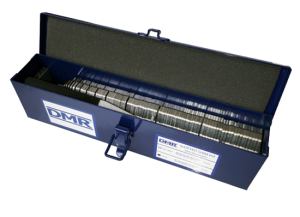

Slotted Shim Kit Features

DMR slotted shim kits were developed to make the shaft alignment process easier. Kits are available in each of the standard sizes: A (2″x2″), B (3″x3″), C (4″x4″), D (5″x5″), E (6″x6″), and H (8″x8″) and each kits contain 20 shims in each of the following thickness: .001, .002, .003, .004, .005, .010, .015, .020, .025, .050, .075, .100, .125. The convenient carrying case is of sturdy steel construction, to keep the kit organized the thicknesses are grouped and separated by dividers. The case features Shim Lock to prevent the shims from moving around in transport. A Shim Removal Tool is included to aid in the removal of old shim. Visit our Catalog to view various kit and size options.

Slotted Shim Replacement Packs

For Detailed Specification and Various Shim Sizes you can also check the links below:

To learn about selecting the correct products for your operating environment please contact your local Daemar Technical Sales Representative.