Home >> Seals >> Braided Packing

Braided Packing

The following is listing of our most popular braided packing styles. In addition, our manufacturers fabricate a wide variety of other constructions designed to meet specific customer requirements. Daemar is a proud Distributor of Chemstar Mechanical Packings.

Technical Resources

To see more Daemar products focused on Food & Beverage Processing applications click here

Braided Packing Construction

Braided Packing Interchange

Competitor Interchange chart provides general comparisons only and should be used as “service equals” only. Manufacturer techniques do vary and when in doubt contact a Daemar Technical Representative.

Mechanical Packing Selection

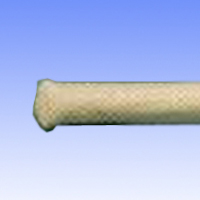

Style 154 FDA

PTFE packing, interlock braid with a break-in lubricant.Food Grade FDA PTFE filaments and break-in lubricant.

Style 154

PTFE packing with PTFE dispersion. A dense firm packing used in valve and slow speed pump applications. Excellent chemical resistance.

Style 154S

PTFE packing treated with an inert lubricant. A soft and resilient packing for chemical pump and valve applications.

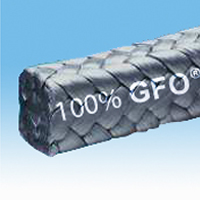

Style 165 (GFO)

GFO graphite filled PTFE fiber with excellent thermal conductivity and chemical resistance. Flexible and pliable and will not harden, swell or become brittle. Packing is stamped with 100% GFO for your reassurance.

Style 165LA

Graphite filled PTFE fibre packing that improves thermal conductivity and will not harden.

Style 170

Aramid fibre packing with an inert lubricant. Extremely durable, highly abrasive resistant packing. Ideal for slurry service.

Style 528

Flax fibre packing, lubricated with tallow and wax. Used for brine, cold water and oil service. Ideal for marine applications.

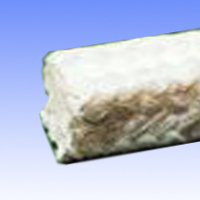

Style 1152

Special syntex fibre, each strand impregnated with PTFE dispersion both prior to and after braiding. Finished packing also has a break-in lubricant. An asbestos replacement packing for general service applications. Good chemical resistance.

Style 1398

Syntex fibre packing impregnated with a high temperature lubricant. Finished packing is surface graphite. An asbestos replacement packing for general service use on pumps and valves.

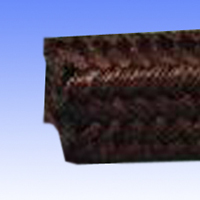

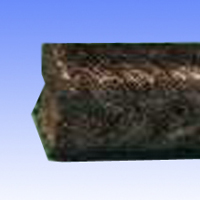

Style 50

Carbon yard packing heavily impregnated with PTFE dispersion. For severe services in pumps or valves handling chemicals, solvents and acids. An ideal packing for paper mill applications.

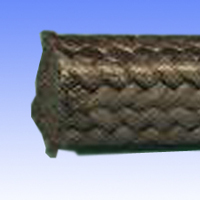

Style 90

Carbon Yarn packing impregnated with graphite dispersion. For severe services in pump and valve applications, including super-heated steam, acids, alkalis, etc.

Style 160

Graphite filament packing impregnated with graphite dispersion. For severe service applications where leakage must be held to a minimum. Excellent chemical resistance.

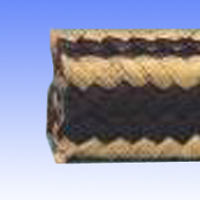

Style 165K

Unique packing combining PTFE graphite with aramid corners. Aramid corners prevent rolls and extrusion. Excellent service packing in severe pump applications. Widely used in paper mills.

Style 182

Spun aramid fiber impregnated with PTFE dispersion and break-in lubricant. Ideal for valves and pumps in abrasive service.

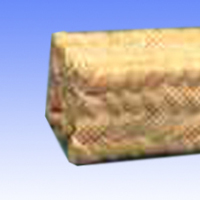

Style 525T

Premier marine service packing made with flax fibers and lubricated with PTFE dispersion. It has low friction and high tensile strength. Excellent for water service and paper mill applications.

Style 1100CR

Braided from a combination of expanded flexible graphite (1100TCP) and high strength carbon fibers (90). Carbon fibers are braided into the corners to provide anti-extrusion and better abrasion resistance in tough applications. Can give virtually leak free performance. 1100CR was independently fire tested to API 589 at API 607 temperatures and pressures.

Style 1100 I

Braided from a combination of expanded flexible graphite and inconel wire. 1100 I retains dimensional stability in high temperature, high pressure environments, and can meet most VOC emission control regulations. 1100 I was independently fire tested to API 589 at API 607 temperatures and pressures.

Style 1100 TCP

Braided from pure expanded graphite. It is resilient, self lubricating, chemically inert and thermally conductive. 1100TCP can be used in both pumps and valves in a wide range of service conditions

Style 1152K

Unique packing combining 1152 and 170 fibers. Aramid corners prevent roll and extrusion. Well suited for abrasive applications and end rings with other packings.

Style 1162IB

Syntex fiber thoroughly impregnated with PTFE, a break-in lubricant is added for start-up. An economical PTFE general service packing.

Style 1190

Special Kynol™ fibers treated with PTFE and break-in lubricant. This is a non-contaminating packing for use in paper mills in almost all pump and valve applications.

Style 1414

High temperature carbon yarn with inconel wire braided over a resilient core thoroughly impregnated with graphite and corrosion inhibitor.

Style 1416

Textured fiberglass fiber packing. It is braided dry with no lubricant. Packing will not swell, shrink and is completely incombustible. Used for sealing over doors. Excellent chemical resistance.

PTFE packing, interlock braid with a break-in lubricant.Food Grade FDA PTFE filaments and break-in lubricant.

Style 1430

Syntex fiber packing treated with a high temperature lubricant and graphite. Soft and pliable for general service on pumps and valves.

Style 2000

Special meta-aramid fiber with PTFE and break-in lubricant. Very conformable and abrasive resistant. highly resistant to degradation and chemical attack. For use in agitators, stock pumps, mixers, etc.

Style 3165

Special blend of PTFE and graphite fibers plus a high temperature lubricant. An economical substitute for style 165. Good chemical and abrasion resistant packing.

Style 4100-Valve Packing

Extruded round valve packing made of 100% expanded virgin PTFE. FDA Suitable (FDA 21 CRR 177.1550)

Style 4200 Joint Sealant

Chemcord 100% expanded virgin PTFE joint sealant. Maximum performance gasket material. FDA approved.